Casting part isolation cooling device

A technology for cooling devices and castings, which is applied in the field of cooling equipment to achieve the effects of reducing workload, easy repair and maintenance, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

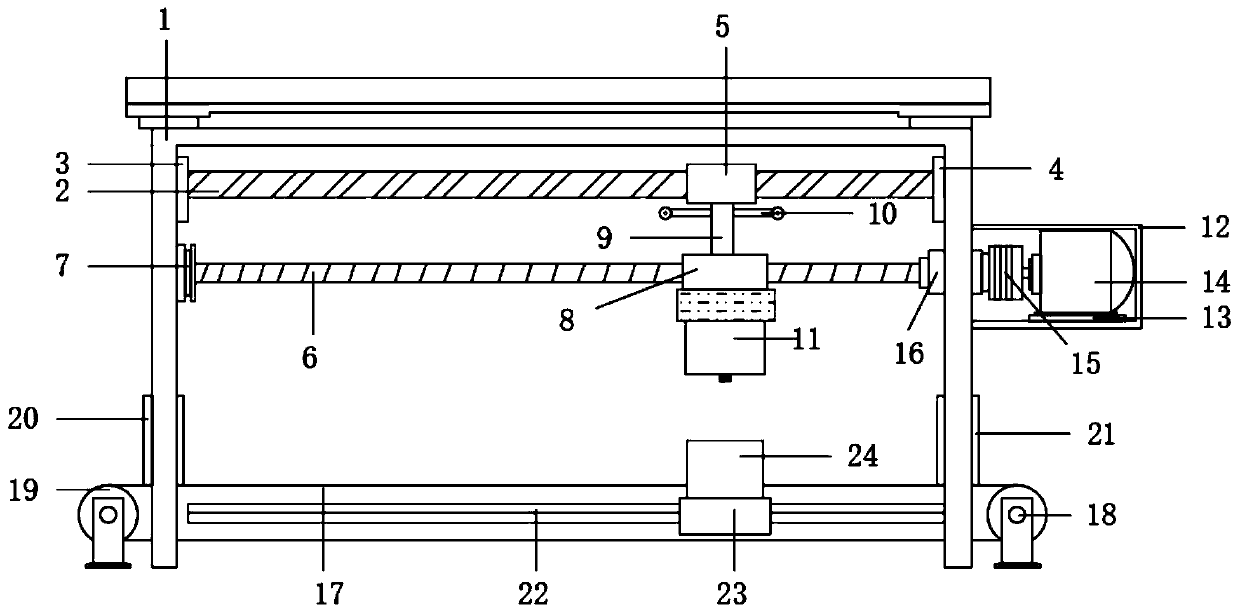

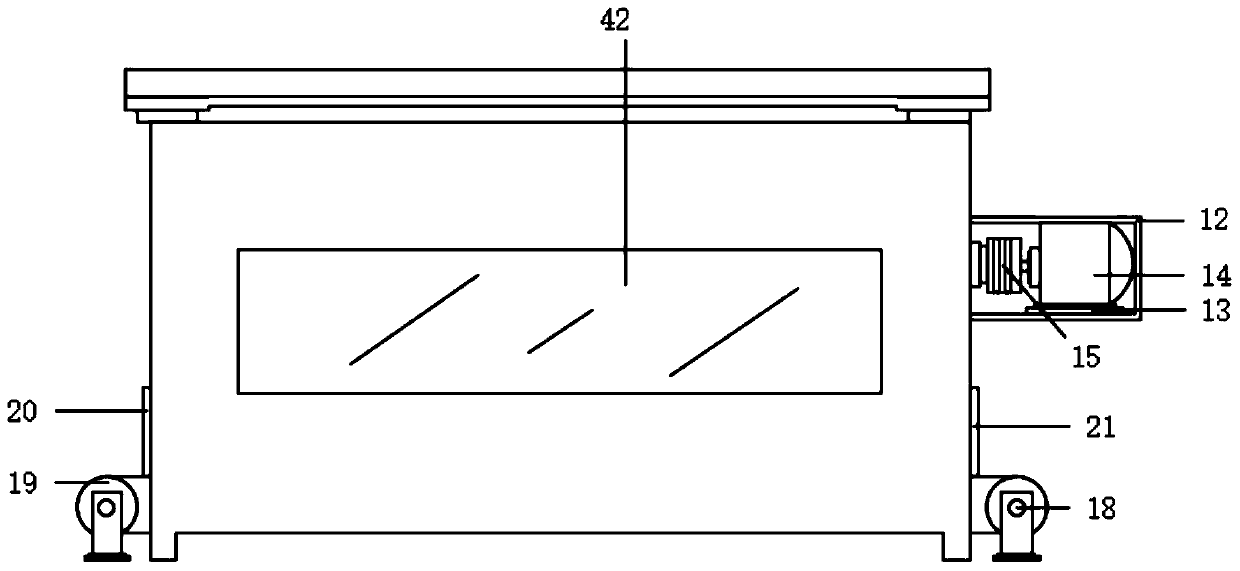

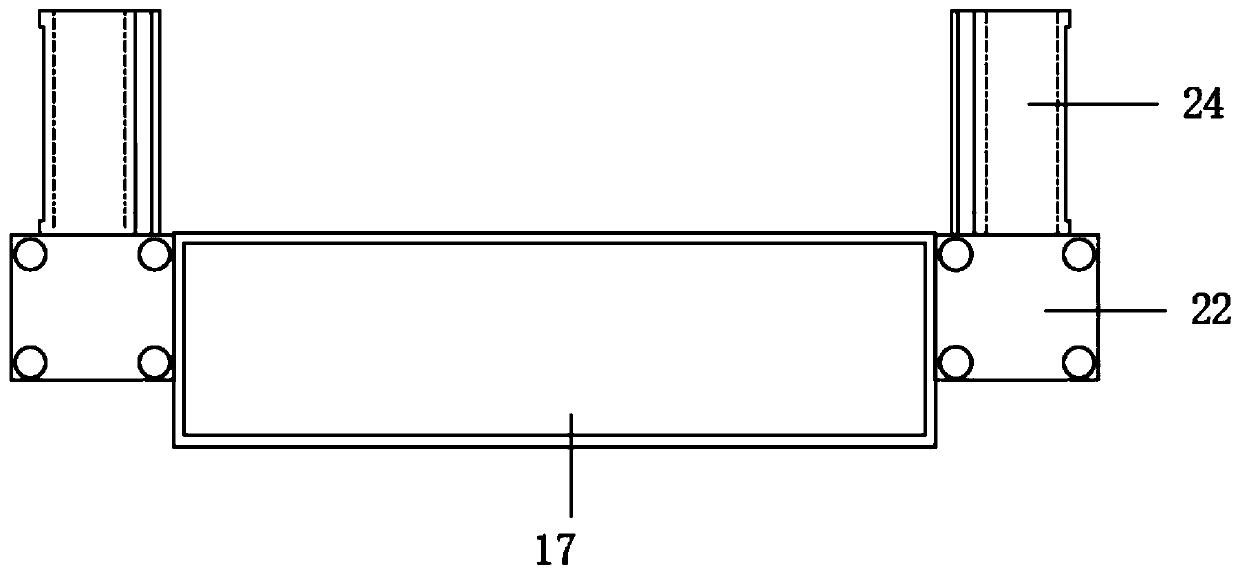

[0026] Such as Figure 1-5 As shown, this specific embodiment adopts the following technical solutions: an isolation cooling device for castings, including a cooling box 1, a transparent observation window 42 is provided on the outer side of the cooling box 1, and a bottom side of the cooling box 1 is provided. There is a No. 2 box door 20, a No. 2 box door 21 is provided on the other side of the cooling box 1 away from the No. 1 box door 20, and a horizontal conveyor belt is provided under the No. 1 box door 20 and the No. 2 box door 21. 17. The end of the horizontal conveyor belt 17 close to the No. 1 box door 20 is connected with a driven wheel 19, and the end of the horizontal conveyor belt 17 close to the No. 2 box door 21 is connected with a driving wheel 18. Both the driving wheel 18 and the driven wheel 19 are Located outside the cooling box 1, the driving wheel 18 is connected to the driven wheel 19 through a horizontal conveyor belt 17, and both sides of the horizont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com