Column type porcelain insulator for high-voltage line

A technology for porcelain insulators and high-voltage lines, which is applied in the direction of insulators, supporting insulators, circuits, etc., and can solve the problems affecting the reliability and safety of high-voltage transmission lines, the fracture and damage of the connection between the body and the base of the porcelain insulator, and the bending moment resistance of the connection body To improve mechanical strength and tensile properties, improve operational reliability and safety, and improve service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

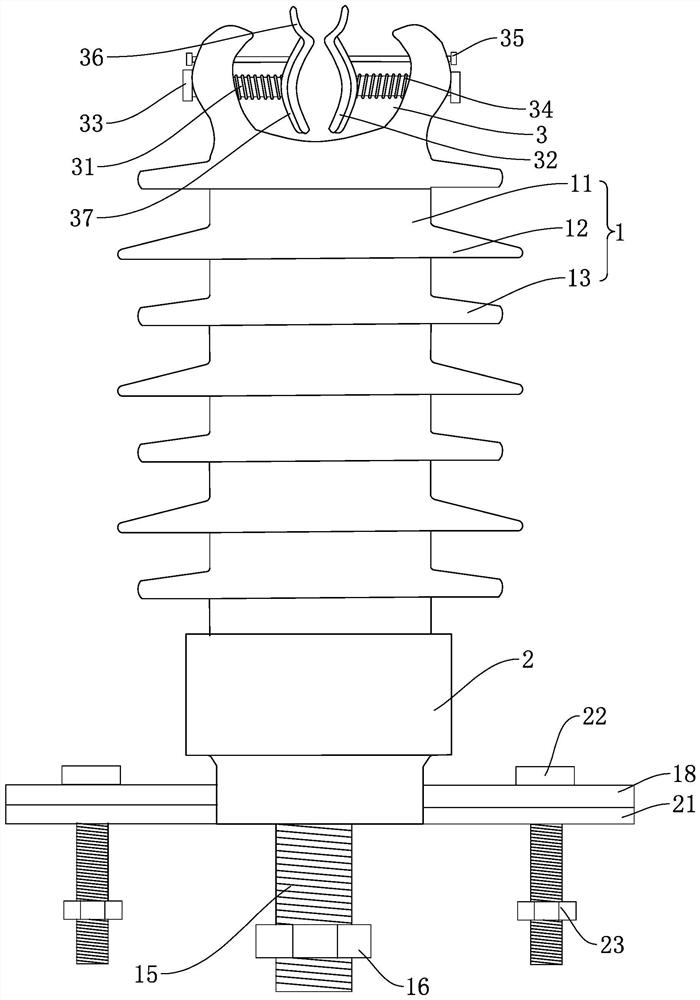

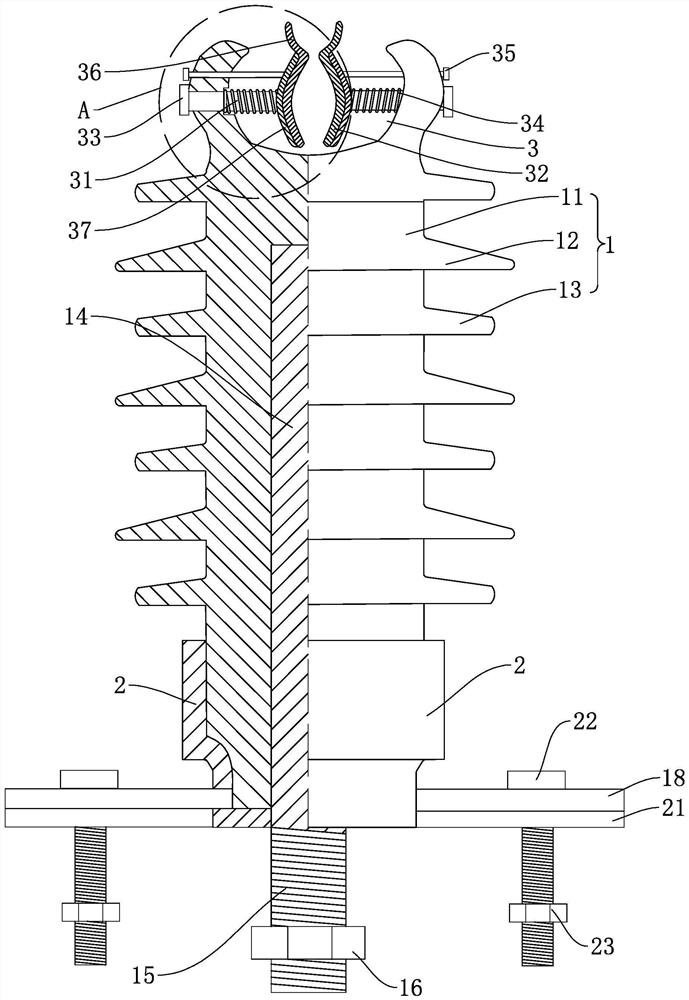

[0038] The following is attached Figure 1-4 The application is described in further detail.

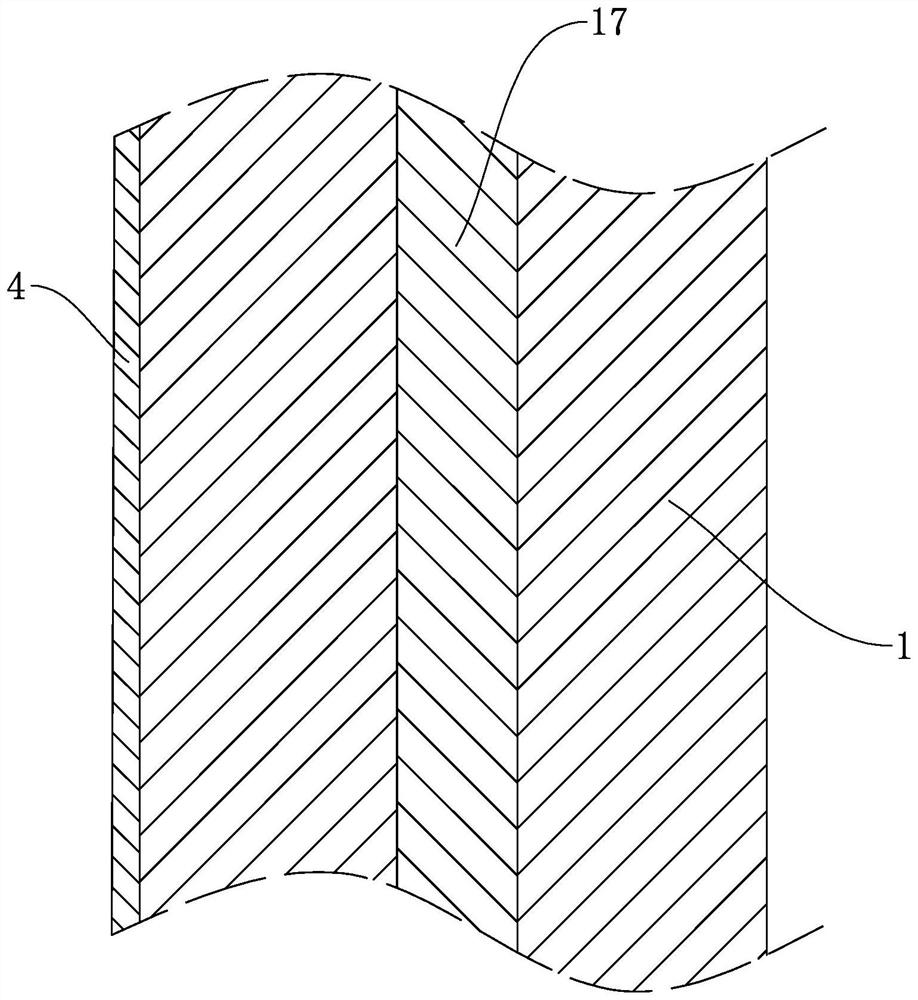

[0039] The embodiment of the present application discloses a column type porcelain insulator for high voltage lines. refer to figure 1 with image 3 A pillar-type porcelain insulator for high-voltage lines, comprising a ceramic insulating core 1 and a base 2, the bottom of the ceramic insulating core 1 is fixedly connected to the base 2. The ceramic insulating core 1 includes a ceramic insulating post 11, several large sheds 12 and several small sheds 13, the ceramic insulating post 11, several large sheds 12 and several small sheds 13 are integrally formed, and several large sheds 12 and several small sheds 13 are arranged at intervals along the length direction of the ceramic insulating column 11 on the outer wall of the ceramic insulating column 11 . One end of the ceramic insulating column 11 is fixedly connected to the base 2, and the other end is provided with a receiving g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com