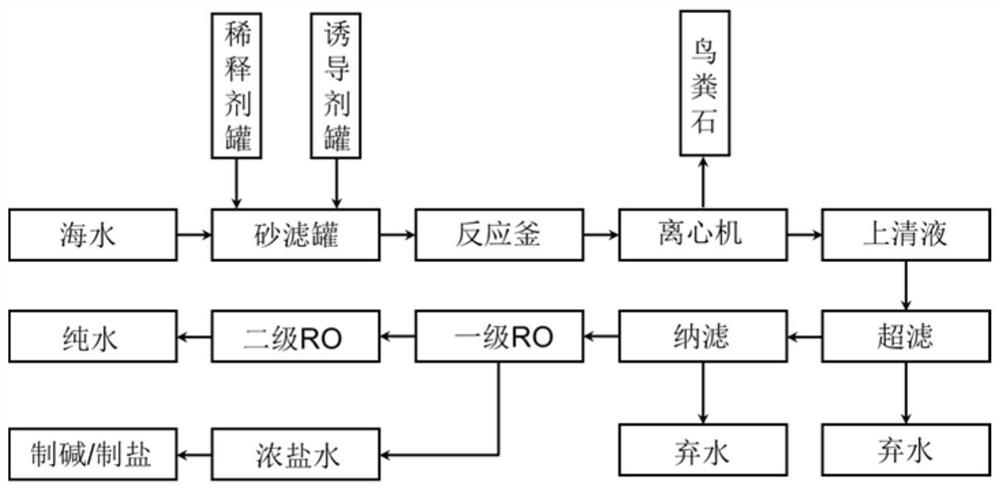

Technological process for struvite extraction in seawater desalination process

A technological process and struvite technology, which is applied in the field of struvite extraction process, can solve problems such as reactor damage, achieve the effects of reducing the pressure before the membrane, avoiding environmental pollution, and reducing the use of medicines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

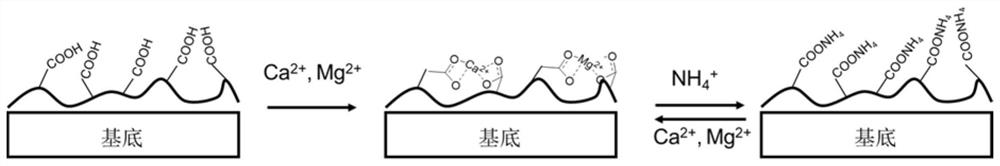

[0032] Synthesis of a reversible polymer material complexing metal ions, polyacrylic acid-ethylene glycol phosphate-polyfurfuryl alcohol interpenetrating network:

[0033] 1) Synthesis of furfuryl alcohol resin (PFA): add 100 g of furfuryl alcohol into a round bottom flask, add 20 ml of deionized water, heat and stir under a nitrogen atmosphere, and control the temperature at 60° C. for 30 minutes. Afterwards, 5ml of concentrated sulfuric acid was diluted to 30ml, and gradually added dropwise to the flask, controlling the temperature at 70-80°C. Cool down to room temperature, add ammonia water to adjust the pH to neutral, centrifuge the product, and dry it under vacuum overnight;

[0034] 2) Synthesis of polyacrylic acid-acrylcystamine (PAA-PACA): Add 1 g of acrylic acid and 100 ml of deionized water into a round-bottomed flask, heat and stir under a nitrogen atmosphere, and control the temperature at 75° C. for 30 minutes. 20 g of acrylic acid and an equivalent amount of amm...

Embodiment 2

[0037] Other parts are identical with embodiment one, adopt the product polyacrylic acid-acrylcystamine-polyfurfuryl alcohol interpenetrating network coating formulation of embodiment one and spray sample preparation to include the following:

[0038] The above paint components are: water: 12, PAA-PACA-PFA: 40, defoamer: 1-3, dispersant 1-3, titanium dioxide: 10, thickener: 0.2, film-forming aid: 3, Barium sulfate: 10, water-based epoxy resin: 30, add deionized water and the above ratio of raw materials in the table into the dispersion tank, after the dispersion is uniform, grind on the machine until the particle size is less than 30 μm; after grinding and degreasing the cold-rolled steel plate, put The paint is sprayed onto the sample plate at a speed of 0.3ml / s, the wet film thickness is ~75μm, and dried in a 50-degree oven.

Embodiment 3

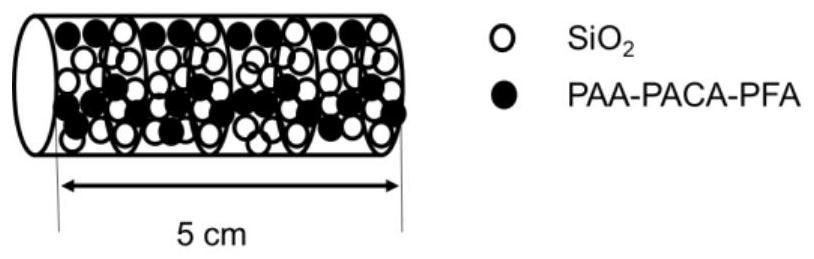

[0040] The struvite reaction device includes: PAA-PACA-PFA packed column and reactor. The inner wall of the pipeline, the sand filter, and the stirring paddle are all sprayed with PAA-PACA-PFA;

[0041] The struvite reactor adopts a stirred reactor, and the reactor mainly includes 20-30m 3 Two concentration tanks, using solar photovoltaic cells to assist distillation and concentration, the purified distilled water is used for industrial distilled water, 3m 3 There are 3 reaction kettles, 3 discharge and feed pumps, 4 metering pumps, 1 centrifuge, and the water passing equipment are all sprayed and coated with PAA-PACA-PFA.

[0042] The PAA-PACA-PFA packed column is a PAA-PACA-PFA mixed SiO with the same diameter as the pipe and a length of 5cm connected before the reactor. 2 Packed columns of particles.

[0043] Use a rotary evaporator to evaporate and concentrate the concentrated seawater to 1 / 10 of its original volume, take an appropriate amount of concentrated solution, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com