Chilled water corrosion inhibitor for inhibiting electrochemical corrosion and preparation method thereof

A technology of corrosion inhibitor and frozen water, applied in the field of frozen water corrosion inhibitor for inhibiting electrochemical corrosion and its preparation, can solve the problems of eutrophication of environmental water, unfriendly environment, long time required for protective layer, etc. The effect of stabilizing pH and not easy to deposit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~3

[0033] A chilled water corrosion inhibitor for inhibiting electrochemical corrosion, its raw material components are shown in Table 1, and its preparation method comprises the following steps:

[0034] Step 1: According to the dosage in Table 1, mix cyanuric chloride, benzotriazole, 2-mercaptobenzothiazole with the solvent, heat up to 95°C and stir for 3 hours after sealing, then cool down to 80°C and keep warm React for 2h to obtain the first mixture;

[0035] Step 2: Stir and cool down the first mixture to 65° C., put in diethoxymethylphenylsilane and stir for 2 hours to obtain the second mixture;

[0036] Step 3: Stir the second mixture to cool down to 40°C, add a pH buffer stabilizer, stir and disperse evenly, and obtain a corrosion inhibitor.

Embodiment 4~6

[0038] A chilled water corrosion inhibitor for inhibiting electrochemical corrosion, its raw material components are shown in Table 1, and its preparation method comprises the following steps:

[0039] Step 1: According to the dosage in Table 1, mix cyanuric chloride, benzotriazole, 2-mercaptobenzothiazole with the solvent, heat up to 90°C and stir for 2 hours after sealing, then cool down to 85°C and keep warm React for 1h to obtain the first mixture;

[0040] Step 2: Stir and cool down the first mixture to 75° C., put in diethoxymethylphenylsilane and stir for 1 hour to obtain the second mixture;

[0041] Step 3: Stir the second mixture to cool down to 35°C, add a pH buffer stabilizer, stir and disperse evenly, and obtain a corrosion inhibitor.

Embodiment 7~9

[0043] A chilled water corrosion inhibitor for inhibiting electrochemical corrosion, its raw material components are shown in Table 1, and its preparation method comprises the following steps:

[0044] Step 1: According to the dosage in Table 1, mix cyanuric chloride, benzotriazole, 2-mercaptobenzothiazole with the solvent, heat up to 95°C and stir for 3 hours after sealing, then cool down to 80°C and keep warm React for 2h to obtain the first mixture;

[0045] Step 2: Stir and cool down the first mixture to 65° C., put in diethoxymethylphenylsilane and stir for 2 hours to obtain the second mixture;

[0046] Step 3: Stir and lower the temperature of the second mixture to 55° C., add 4,4-bipyridine and a pH buffer stabilizer, stir and disperse evenly, and obtain a corrosion inhibitor.

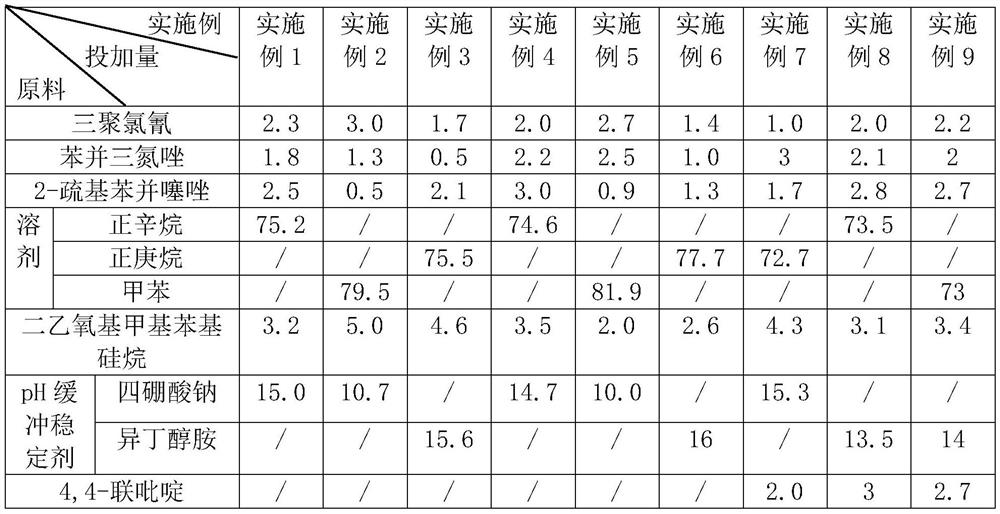

[0047] Table 1. The dosage of corrosion inhibitor raw materials in Examples 1-9 (unit: kg)

[0048]

[0049] Among them, diethoxymethylphenylsilane is purchased from Hubei Xinghengye Techno...

PUM

| Property | Measurement | Unit |

|---|---|---|

| scale inhibition rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com