Organic extractant injection device for metal treatment

A technology of organic extraction agent and injection device, which is applied to the improvement of process efficiency, fixed filter element filter, filtration and separation, etc., can solve the problems of easy occurrence of danger, and achieve the effects of avoiding clogging, fast and effective buffering, and reducing vibration damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

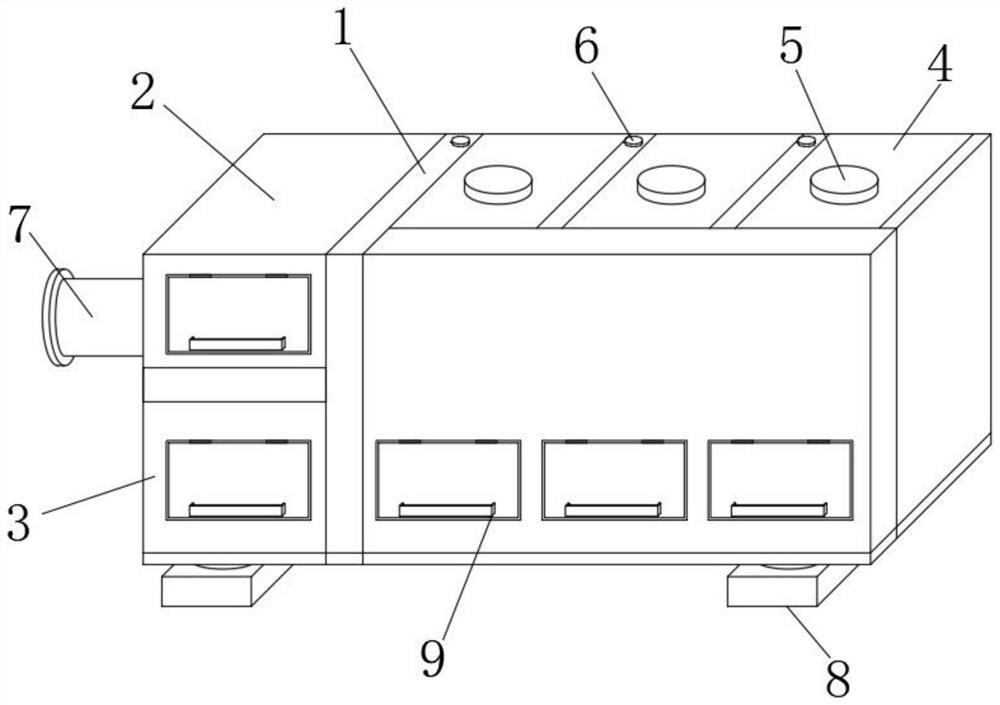

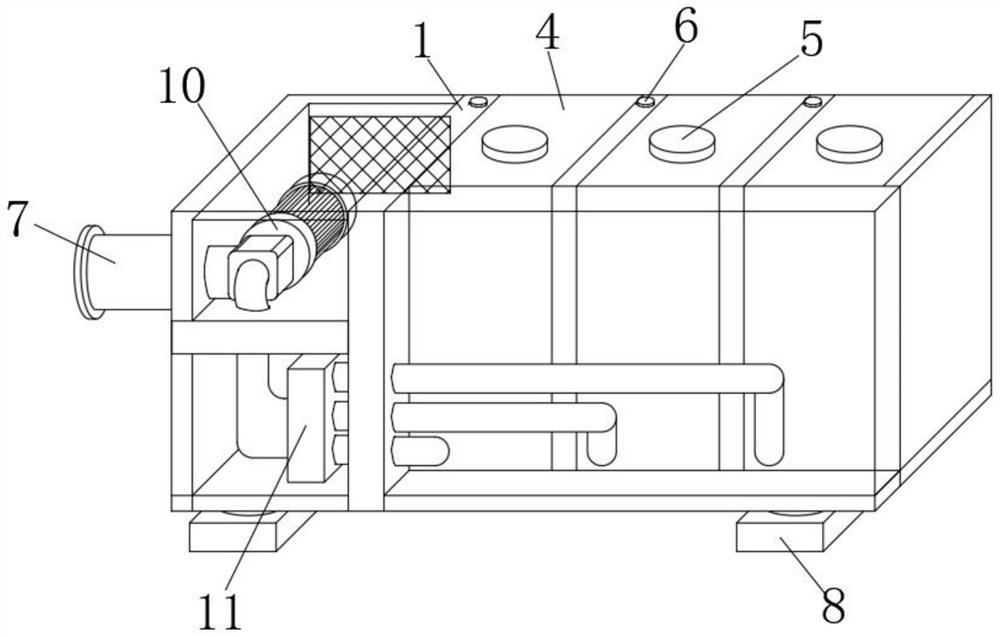

[0029] see Figure 1 to Figure 5 , the present invention provides a technical solution: an organic extraction agent injection device for metal treatment, comprising a main frame 1, a support seat 8 is provided on the lower side of the main frame 1, and a pump box 2 and a valve are provided at one end of the main frame 1 The inside of the box 3, the pump box 2 and the valve box 3 are respectively provided with a suction pump 10 and a multi-way valve 11, the suction port of the suction pump 10 is connected with the multi-way valve 11 through a pipeline, and the water outlet of the suction pump 10 is provided with a mounting plate 22 , one end of the mounting plate 22 is connected with the filter cartridge 7, the other end of the main frame 1 is connected with the extraction agent box 4 through the connection mechanism 6, the upper end of the extraction agent box 4 is provided with an addition port 5, and the lower end discharge port of the extraction agent box 4 passes through T...

Embodiment 2

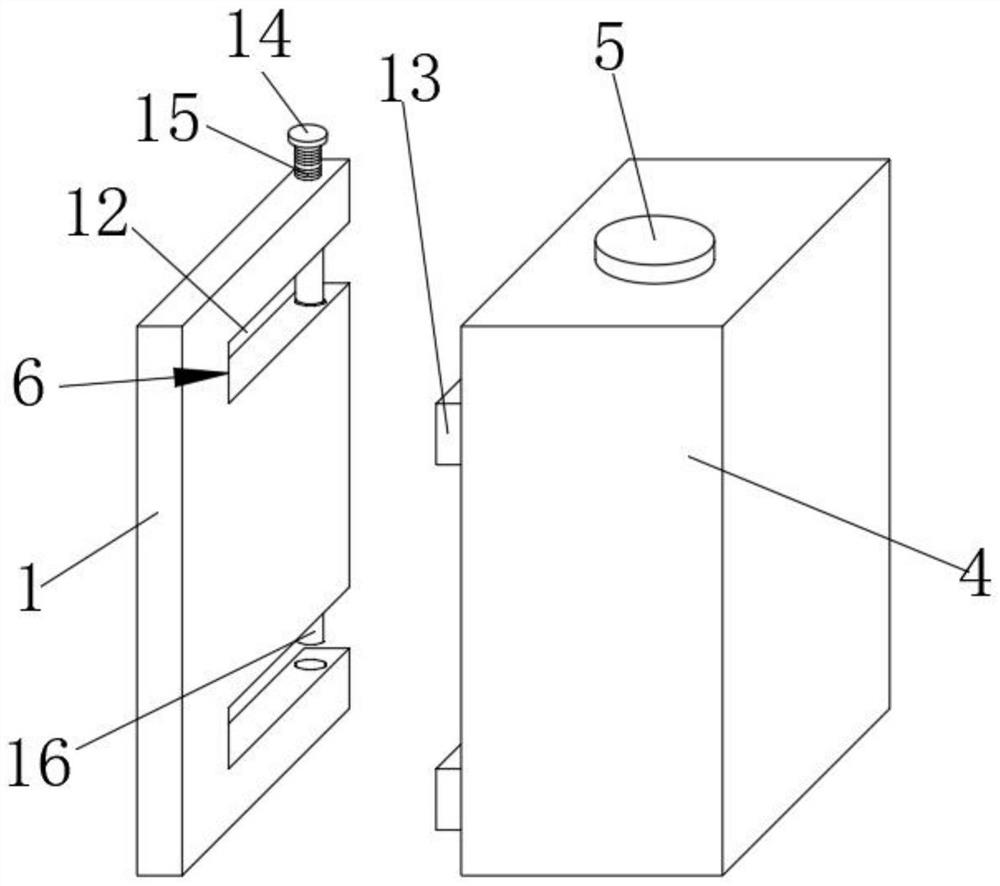

[0034] see Figure 1 to Figure 5 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: the connecting mechanism 6 includes a connecting slot 12 opened on the main frame 1 and a connecting plate 13 fixed on one side of the extraction agent box 4, connecting Plate 13 is inserted into the inside of connecting slot 12, and one side of main frame 1 is provided with post 16, and the upper end of post 16 is provided with threaded post 15, and the upper end of threaded post 15 is provided with swivel head 14; Post post 16 and thread The column 15 has an integrated structure, the connecting slot 12 and the connecting plate 13 adopt an interference fit, and the inserting post 16 passes through the connecting slot 12 and the connecting plate 13, and only the threaded post 15 and the inserting post 16 need to be rotated by the rotating head 14 , unscrew the threaded post 15 from the main frame 1, pull out the post 16 from the connection board 13 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com