Energy-saving and efficient wind power generation blade unit

A technology of wind power generation blades and units, applied in the field of wind energy, can solve the problems of fan blade running wear and wind power can not be well utilized, and achieve the effect of preventing mechanical wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

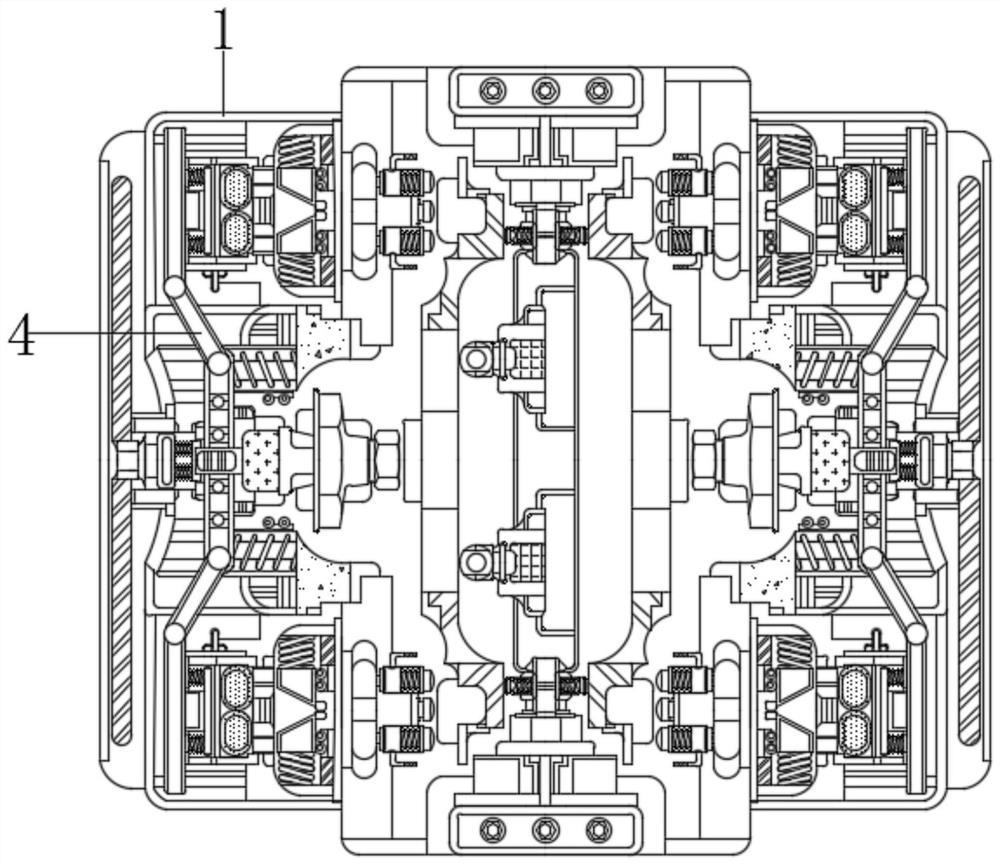

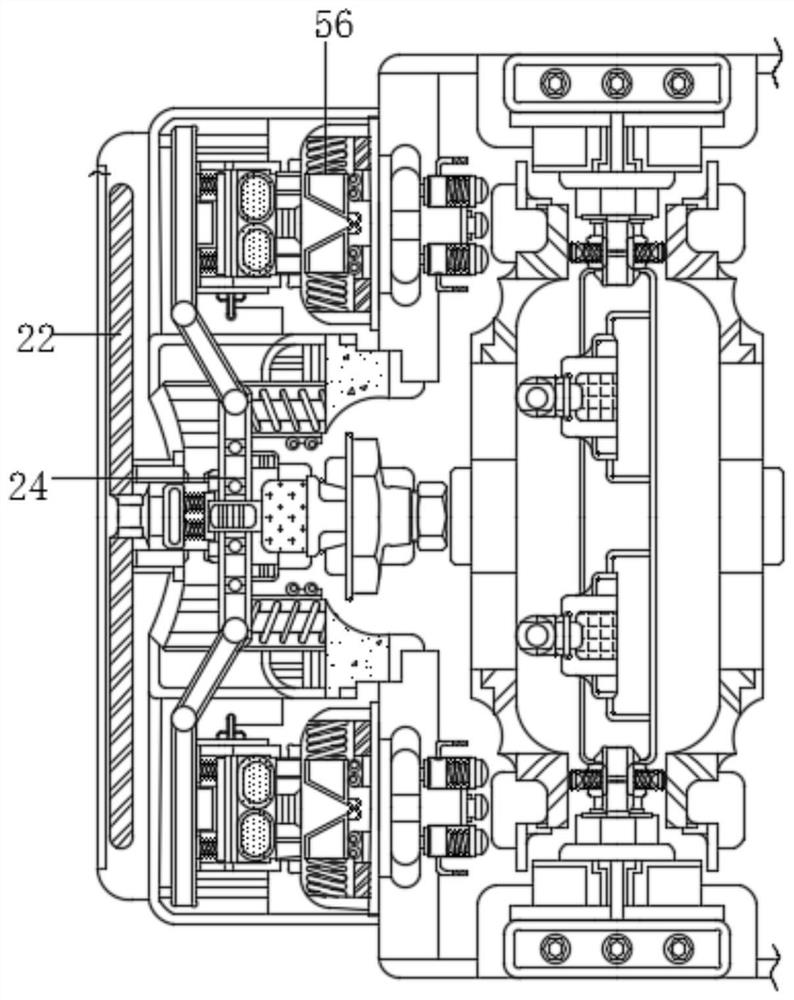

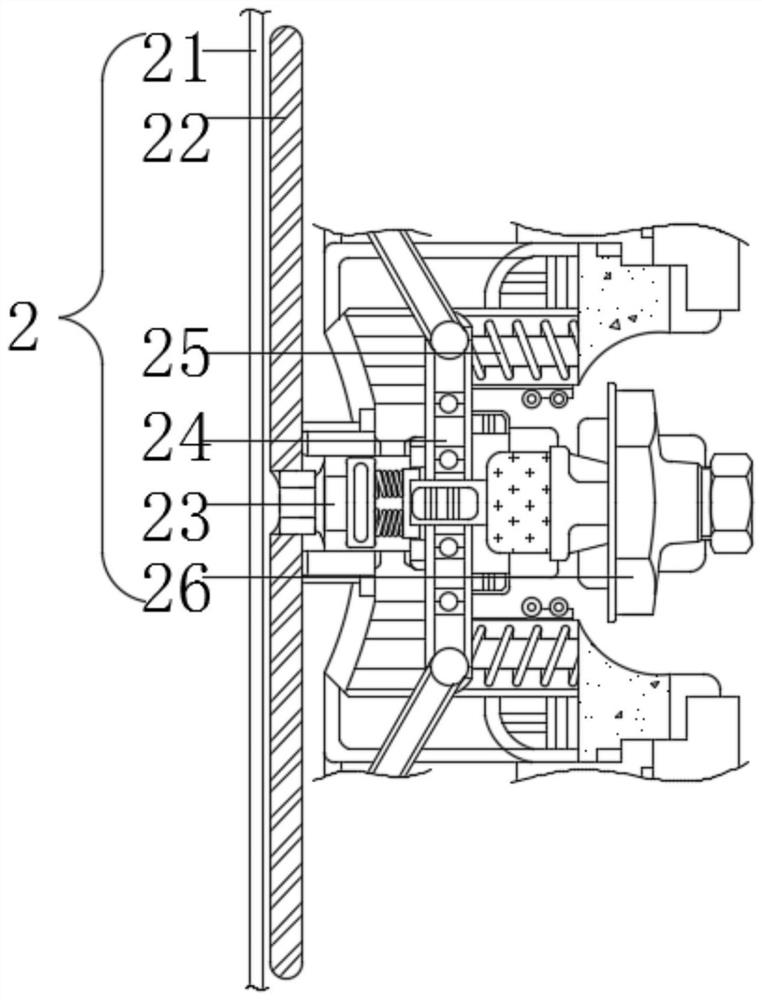

[0025] see figure 1 , figure 2 , image 3 ,and Figure 4 , an energy-saving and high-efficiency wind power generation blade unit, comprising a casing 1, a push mechanism 2 is movably connected to the left end of the casing 1, and the inside of the push mechanism 2 includes an air gathering port 21, and a force plate 22 is movably connected to the right end of the wind gathering port 21, and the force receiving The right end of plate 22 is fixedly connected with connection block 23, and the right end of connection block 23 is fixedly connected with guide rod 24, and the right end of guide rod 24 is movably connected with compression spring 25, and the right end of guide rod 24 is fixedly connected with top block 26, and there are two top blocks 26, And with respect to the inner center line of the housing 1, the left and right are symmetrical, the top block 26 is located at the left end of the trigger ring 31, the force plate 22 is located at the left end of the inner wall of...

Embodiment 2

[0028] see figure 1 , figure 2 , image 3 ,and Figure 5 , an energy-saving and high-efficiency wind power generation blade unit, comprising a casing 1, a push mechanism 2 is movably connected to the left end of the casing 1, a steering mechanism 3 is movably connected to the right end of the push mechanism 2, and a tension rod 4 is movably connected to the upper end of the push mechanism 2, and the pulling force The upper end of the rod 4 is movably connected with a lubricating mechanism 5. The inside of the lubricating mechanism 5 includes a moving rod 51. The right end of the moving rod 51 is fixedly connected with a buffer spring 52. The right end of the buffer spring 52 is fixedly connected with a pressure rod 53. The right end of the pressure rod 53 is movably connected with a lubricating oil tank. 54. The right end of the lubricating oil tank 54 is fixedly connected with a conduit 55, and the right end of the conduit 55 is movably connected with a blocking mechanism ...

Embodiment 3

[0031] see Figure 1-5, an energy-saving and high-efficiency wind turbine blade unit, comprising a casing 1, a pushing mechanism 2 is movably connected to the left end of the casing 1, and the pushing mechanism 2 includes an air collecting port 21, and the right end of the air collecting port 21 is movably connected with a force-bearing plate 22, which receives the force A connecting block 23 is fixedly connected to the right end of the plate 22, a guide rod 24 is fixedly connected to the right end of the connecting block 23, a compression spring 25 is movably connected to the right end of the guide rod 24, and a top block 26 is fixedly connected to the right end of the guide rod 24. There are two top blocks 26. , and is symmetrical about the inner center line of the shell 1, the top block 26 is located at the left end of the trigger ring 31, the force plate 22 is located at the left end of the inner wall of the shell 1, the left end of the shell 1 is provided with a force plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com