Clamp and method for fastening a clamp

A technology of clamps and clamping bands, applied in the direction of flange connection, through components, couplings, etc., can solve problems such as damage to functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

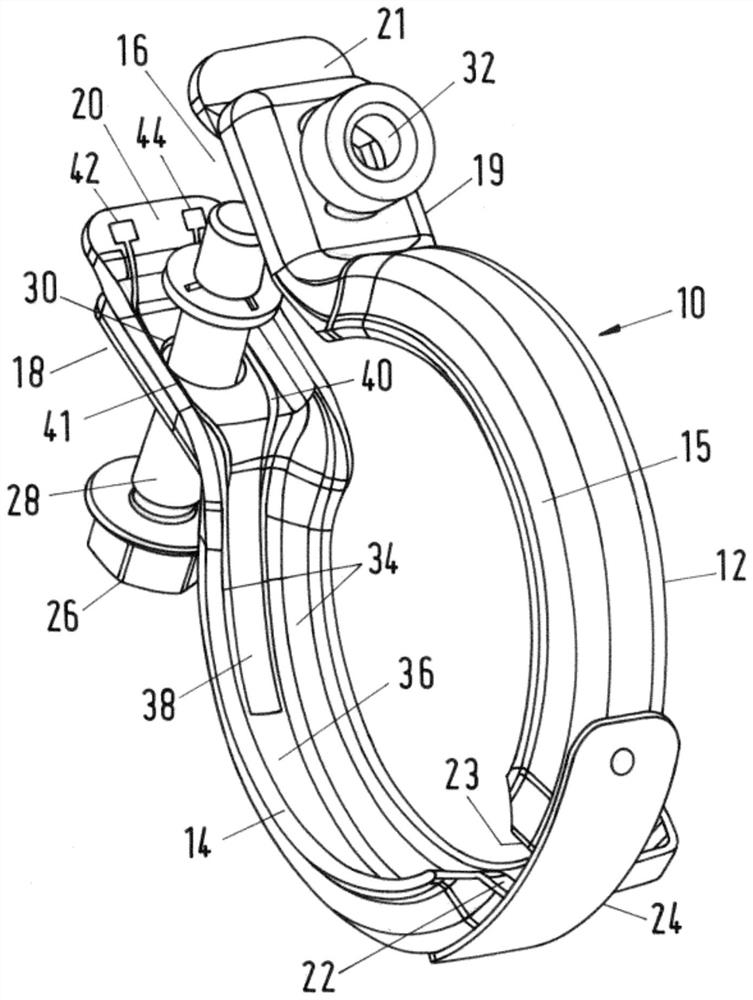

[0049] figure 1 A perspective view of a clamp 10 is shown in an open state prior to installation. The clamp 10 has a clamping strip 12 divided into two half clamps 14, 15, wherein at an opening 16 of the clamp 10, ends 18, 19 is bent to form a plurality of tensioning heads 20, 21 (which may also be designated as split flanges) so that the ends 18, 19 abut each other when the clamp 10 is closed.

[0050] At their ends 22 opposite the tensioning heads, the two clamp halves 14, 15 are connected to each other in an articulated manner by means of a connecting piece 24, so that the clamp 10 The opening 16 can be widened by pivoting the clamp halves 14, 15 in opposite directions in order to place the clamp 10 on a plurality of pipe elements (not shown).

[0051] The two tensioning heads 20, 21 can be clamped to each other by means of a tensioning screw 28, here serving as a tensioning element 26, wherein on the tensioning head 20 all parts of said tensioning screw 28 are provided. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com