Full-automatic feather straightening device for badminton processing

A fully automatic, badminton technology, applied in the direction of sports accessories, etc., can solve the problems of general heating effect, poor feather straightening effect, single heating position, etc., to ensure heat insulation effect, guarantee straightening effect, and improve heating efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

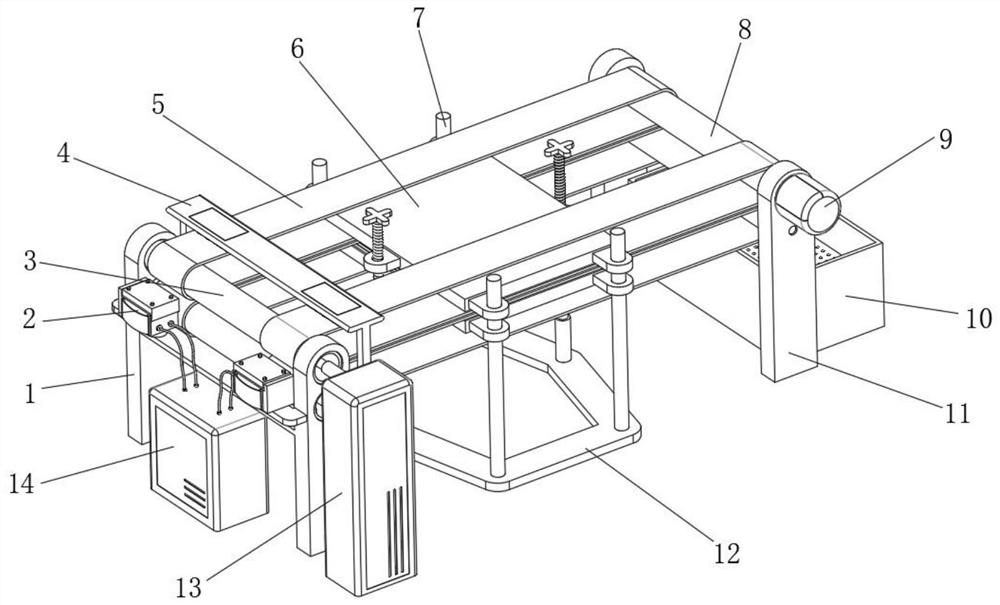

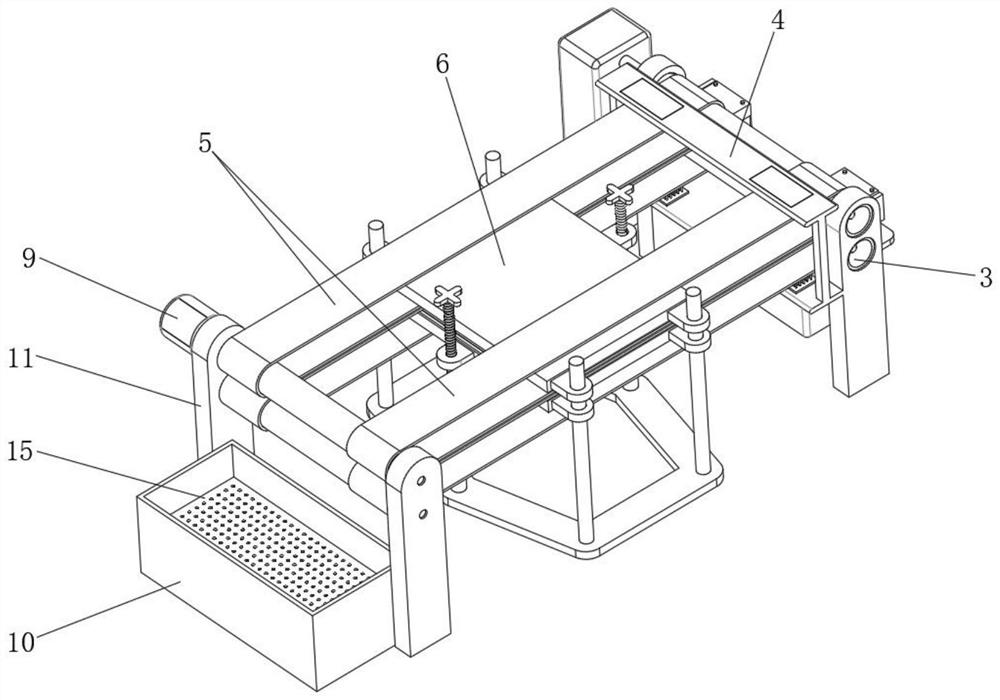

[0033] A kind of automatic feather straightening device for badminton processing, such as Figure 1-6As shown, it includes a first mounting frame 1 and a second mounting frame 11, the inner wall of the first mounting frame 1 is rotatably connected with two hollow drums 3, and the outer wall of the hollow drum 3 and the inner wall of the first mounting frame 1 are provided with corresponding Adapted ring chute, evenly distributed balls 23 are rolled and connected in the ring chute, the outer wall of one side of the second installation frame 11 is fixed with a drive motor 9 by bolts, and the output end of the drive motor 9 is connected through a gear and shaft transmission There are two driving drums 8, the two driving drums 8 form a transmission relationship with the two hollow drums 3 through two conveyor belts 5, the two conveyor belts 5 are arranged in parallel up and down, and the hollow drums 3 are far away from A heating assembly 2 is arranged on one side, and a heater 13...

Embodiment 2

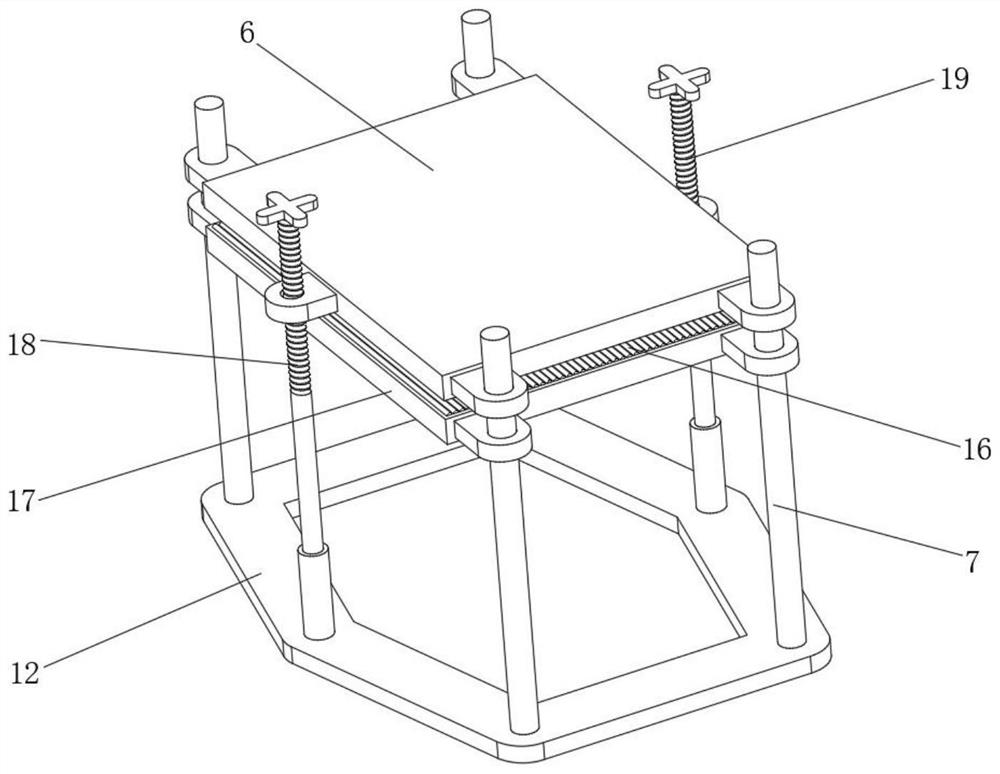

[0040] A kind of automatic feather straightening device for badminton processing, such as figure 2 , image 3 As shown, in order to improve the straightening effect; this embodiment makes the following improvements on the basis of Embodiment 1: a support seat 12 is provided below the conveyor belt 5, and a guide post 7 is integrally provided on the outer wall of the top of the support seat 12, and the guide post 7 The outer wall is slidably connected with a first press plate 6 and a second press plate 17, the first press plate 6 and the second press plate 17 are respectively located inside the two conveyor belts 5, and the inner wall on one side of the first press plate 6 is threadedly connected with a first adjusting screw 18, The inner wall of the primary side of the second pressing plate 17 is threadedly connected with a second adjusting screw 19, and the first adjusting screw 18 and the second adjusting screw 19 are rotatably connected to the top inner wall of the support...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com