Automatic circular pipe tracking and cutting system and method

A technology of automatic tracking and cutting system, applied in the direction of tubular items, manufacturing tools, other household appliances, etc., can solve the problems of reducing cutting speed, consuming time, increasing cutting process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

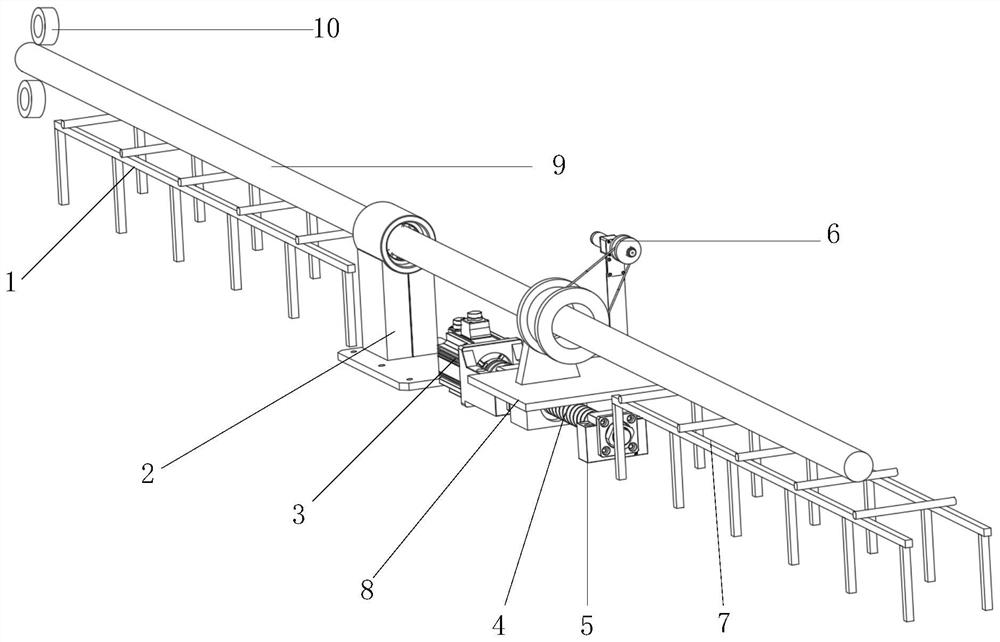

[0052] Such as figure 1 As shown, a circular pipe automatic tracking cutting system includes a first conveyor belt 1, a circular pipe positioning device 2, a drive motor 3, a screw rod 4, a base 5, a cutting machine 6, a second conveyor belt 7, and an installation platform 8 and code wheel 10.

[0053]The first conveyor belt 1 and the second conveyor belt 7 are arranged on the installation surface along the same straight line, and the transmission directions of the first conveyor belt 1 and the second conveyor belt 7 are consistent, and the circular pipe positioning device 2 is located at Between the first conveyor belt 1 and the second conveyor belt 7, and the circular tube positioning device 2 is arranged close to the first conveyor belt 1, and the cutting machine 6 is arranged between the circular tube positioning device 2 and the second conveyor belt 7 , and the cutting machine 6 is arranged on the installation platform 8, the installation platform 8 is connected to the s...

Embodiment 2

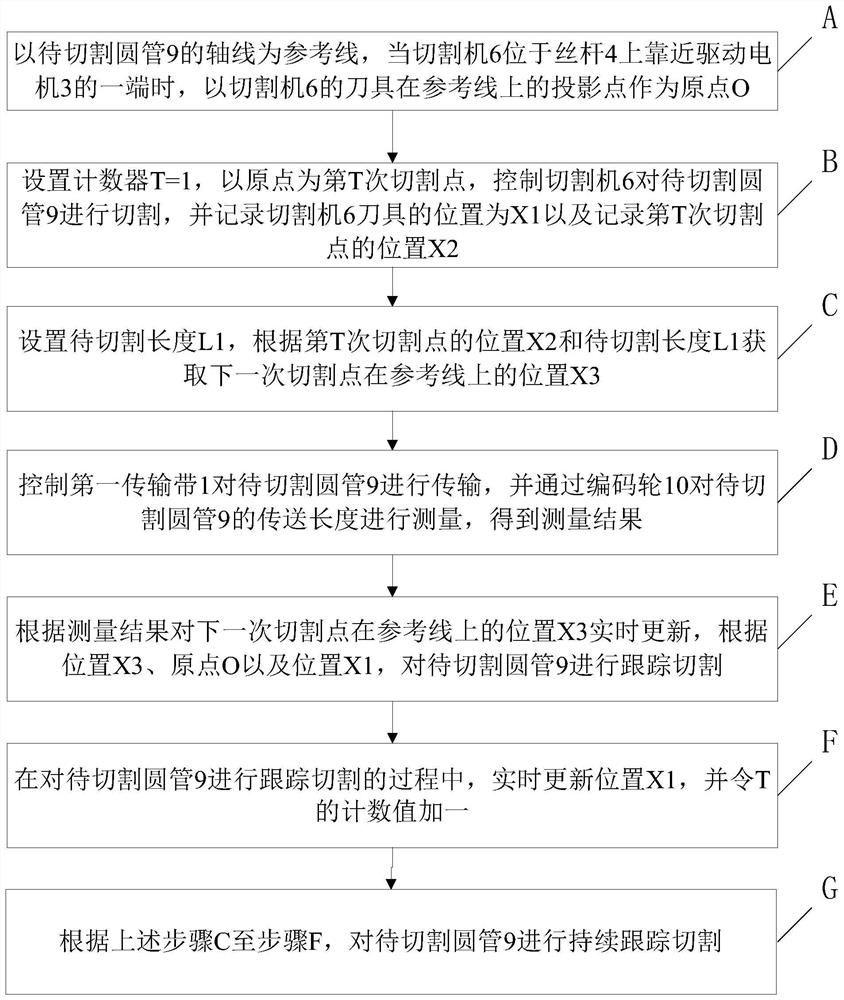

[0068] Such as figure 2 As shown, the embodiment of the present invention provides a round pipe automatic tracking cutting method based on the round pipe automatic tracking cutting system, which is used to track and cut the round pipe 9 to be cut, place the round pipe 9 to be cut on the first conveyor belt 1, Through the circular pipe positioning device 2, including:

[0069] A. Taking the axis of the round pipe 9 to be cut as the reference line, when the cutting machine 6 is located at the end of the screw mandrel 4 close to the drive motor 3, the projection point of the cutter of the cutting machine 6 on the reference line is used as the origin O;

[0070] B, counter T=1 is set, take the origin as the T cutting point, control the cutting machine 6 to cut the round pipe 9 to be cut, and record the position of the cutting machine 6 cutter as X1 and record the position X2 of the T cutting point;

[0071] C. Set the length L1 to be cut, and obtain the position X3 of the next c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com