Method for dismounting rolling mill stand in limited space

A rolling mill stand, limited space technology, used in cranes, trolley cranes, transportation and packaging, etc., can solve the problems of unable to meet the lifting requirements of demolition work, unable to meet the lifting requirements of rolling mill stands, etc., and reduce the number of special spreaders. The effect of reducing the time, reducing construction measures, and reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention is further illustrated below by specific examples.

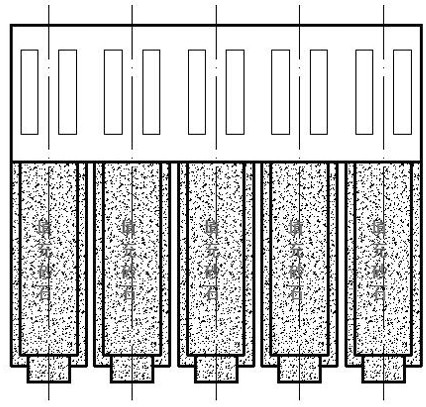

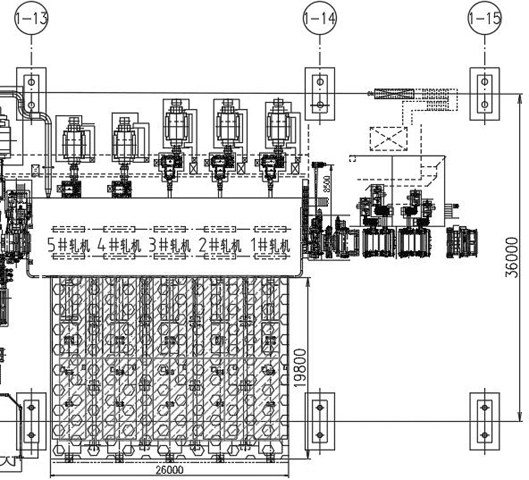

[0018] Such as Figure 1~Figure 5 As shown, a method for dismantling a rolling mill stand in a confined space, including

[0019] Step 1. According to the environmental conditions, when the transmission side cannot carry out the hoisting operation of the truck crane station, choose to carry out the hoisting operation on the operation side. Among them, when the operation side of the rolling mill is the roll changing device, the roll changing device should be completed before the rack is removed. Remove to ensure the smooth flow of vehicles;

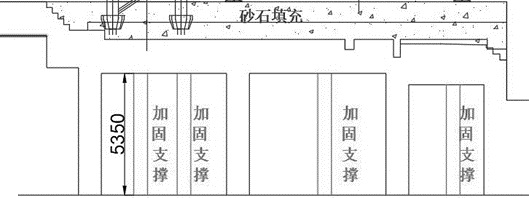

[0020] Step 2. After the dismantling of the roll changing device is completed, in order to ensure that the truck crane and transport vehicles can be close to the rolling mill frame to successfully complete the hoisting and transportation work, the roll changing pit is filled with sand and gravel;

[0021] Step 3. After the sand and gravel filling in the rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com