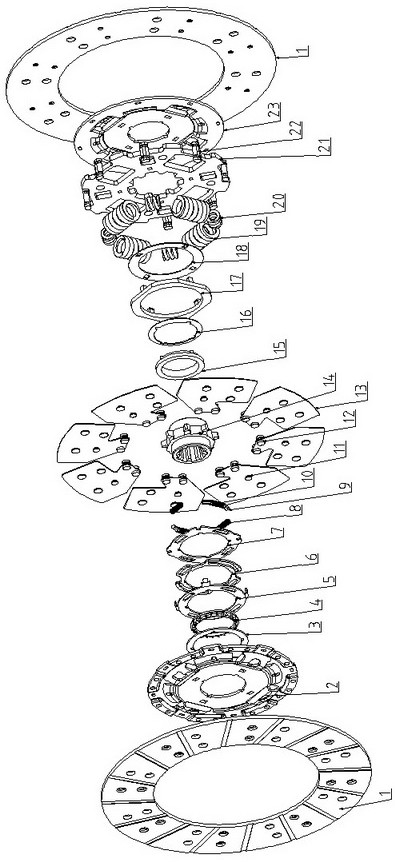

Five-stage vibration reduction clutch driven plate assembly

A moving disc and assembly technology, applied in the field of auto parts, can solve problems such as cold car idling, hot car idling, creeping driving, etc., achieve good vibration reduction and improve NVH problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention includes friction sheet 1, wave sheet 13, friction plate and waveform sheet rivet 11, wave sheet and driven disc rivet 12,

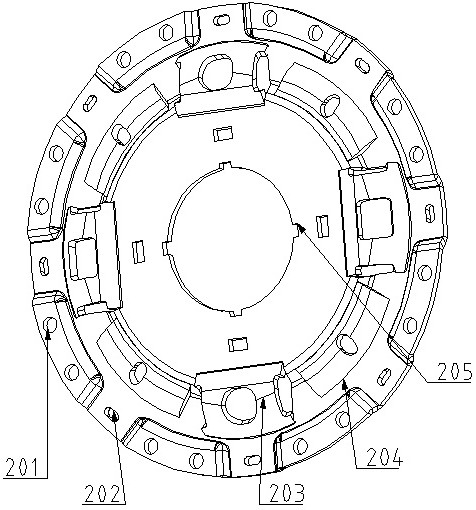

[0052] A, the damping ring 406 side surface of the damper ring 404 is damping the ring reinforcing ring 404, the damper ring inner diameter 403 is the damping ring reinforcing ring 404 and the damping ring main ring 406 shared inner surface, damping the outer diameter 402 is the damping ring main The outer surface of the ring 406 is formed in the outer ring of the damping ring reinforced ring 404, and the damping ring buckle 401 and the driven disk inner diameter positioning card 405 are fixed on the upper surface of the damping ring main ring 406;

[0053] The damping ring 4 is assembled from the driven disc 2, the damping ring buckle 401 inserts the driven disk widow 205;

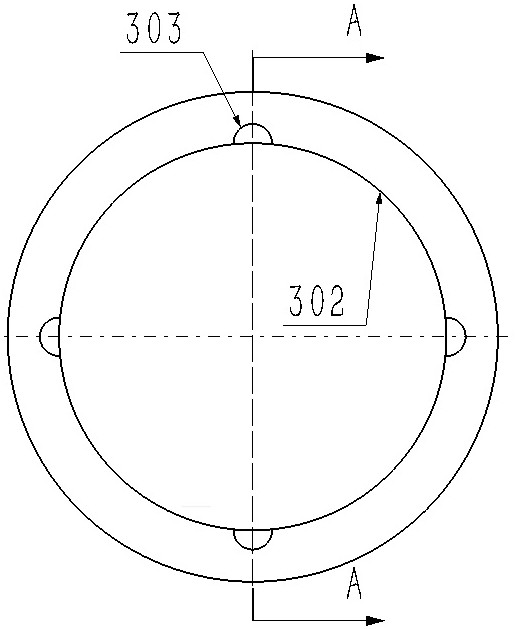

[0054] B. The friction gasket body 304 of the friction gasket 3 has a friction gasket groove 303, and the corresponding friction gasket 3 is friction washer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com