Total detection machine for gear shifting shaft

A technology of shifting shaft and cover, applied in the testing of mechanical parts, the testing of machine/structural parts, and by detecting the appearance of fluid at the leak point, etc., can solve the problems of inconvenient detection, high cost and low detection efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

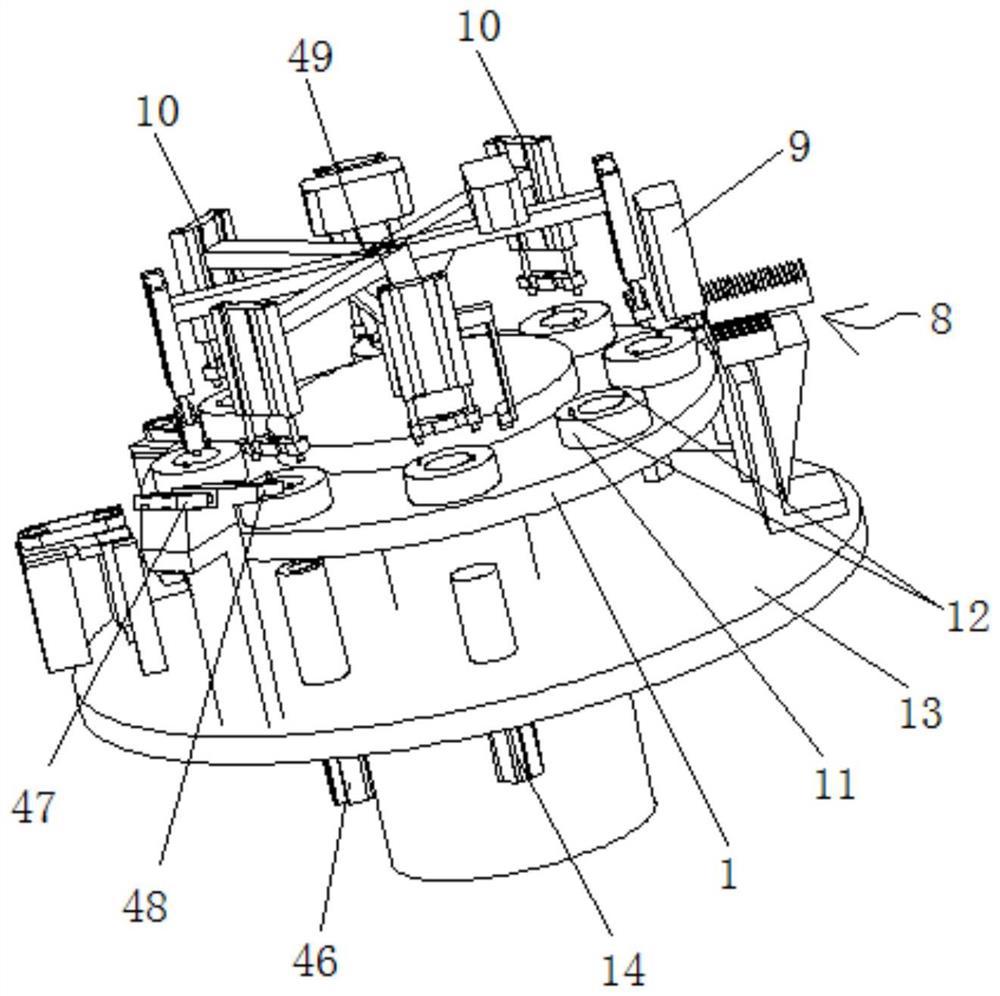

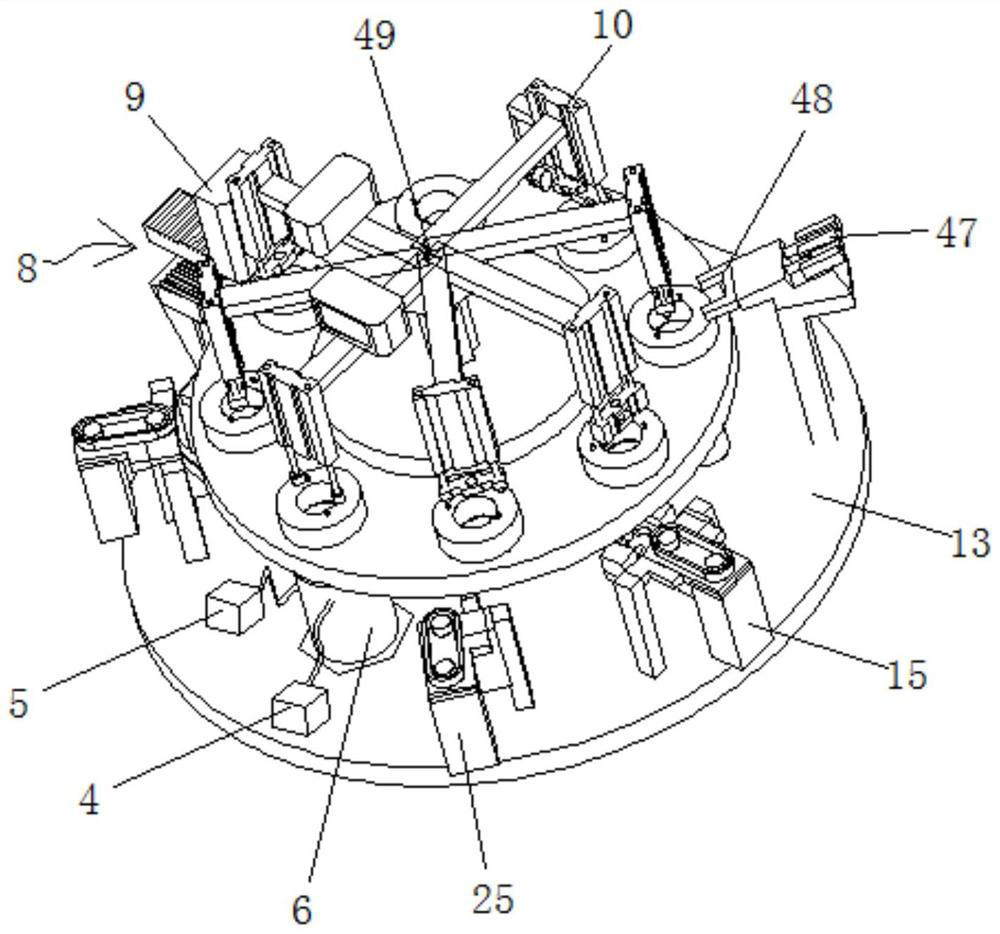

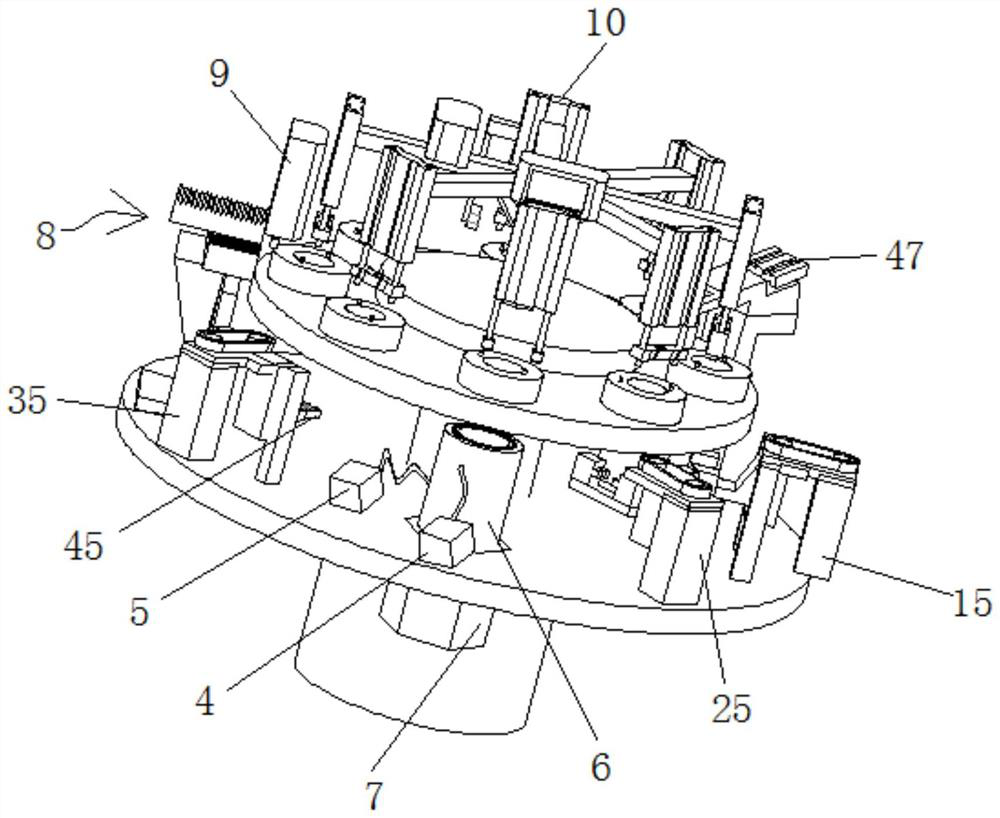

[0041] like Figure 1 to Figure 11As shown, the present embodiment provides a gearshift shaft general inspection machine, including a disk 1, a detection device 1, a detection device 3 and a positioning device. A plurality of detection holes are used to place the shift shaft 3 and penetrate up and down; the positioning device is fixedly erected above the disc 1, and is used to locate the shift shaft 3 at the multiple detection holes; the detection device 1 and the detection device 3 are arranged along the circle The circumferential interval of the disc 1 is installed under the disc 1, the detection device 1 is used to detect whether the shift shaft 3 at the corresponding detection hole is in the neutral position, and the detection device 3 is used to detect the shift shaft 3 at the corresponding detection hole The amount of shifting force when rotating.

[0042] During detection, at first, manually place a plurality of shift shafts 3 to be detected in a plurality of detection...

Embodiment 2

[0051] On the basis of Embodiment 1, this embodiment also includes a detection device five, which is fixedly installed under the disc 1, and is used to detect the airtightness of the shift cover 3-1 on the shift shaft 3 at the corresponding detection hole. The detection device 1, the detection device 3 and the detection device 5 are sequentially distributed along the circumferential direction of the disc 1 at intervals. During detection, the corresponding motor drives the disc 1 to rotate so that the corresponding detection hole rotates to the top of the detection device five, and then the detection device five detects the air tightness of the shift cover 3-1 on the shift shaft 3, which is convenient for detection.

Embodiment 3

[0053] On the basis of Embodiment 2, in this embodiment, the detection device five includes an air tightness detector 4, an air compressor 5, a sealing cylinder 6 and an air tightness detection cylinder 7, and the sealing cylinder 6 is vertically installed on the bottom of the disk 1. Below, it can move up and down, and its upper end is open. The air compressor 5 is fixedly installed on the sealing cylinder 6. It communicates with the inside of the sealing cylinder 6 through a hose, and an air valve is fixedly installed on the pipeline, and the air tightness detection cylinder 7. The air tightness detector 4, the air compressor 5 and the air valve are respectively connected to the controller through lines; the air tightness detection cylinder 7 is fixedly installed on the workbench 13 corresponding to the position below the sealing cylinder 6, and its telescopic end is along the sealing cylinder. 6, and is fixedly connected with the lower end of the sealing cylinder 6, which ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com