Automatic balancing device of tumbler centrifuge and automatic balancing method of automatic balancing device

A centrifuge and trimming technology, which is applied to centrifuges and other directions, can solve problems such as safety, hidden dangers, and high requirements, and achieve the effect of saving manual trimming steps and improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

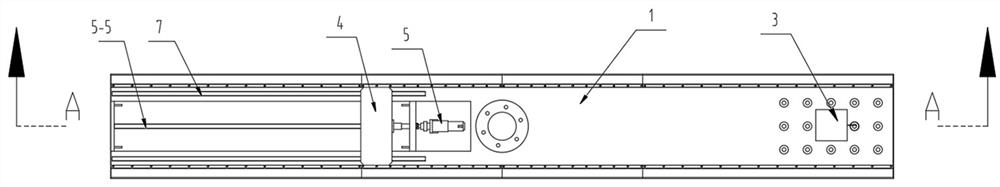

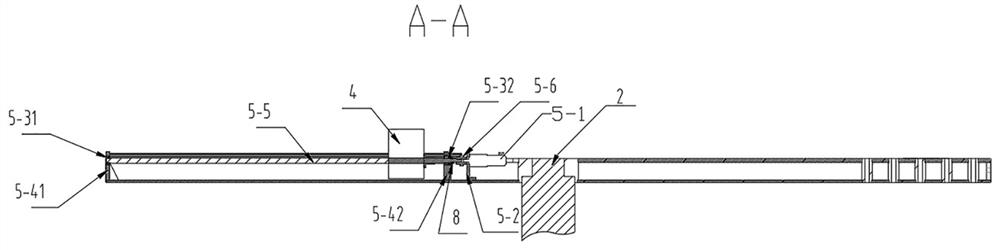

[0047] refer to Figure 1-2 , an automatic balancing device for a rotating arm centrifuge, comprising a centrifugal rotating arm 1, a centrifuge driving spindle 2, a film pressure sensor 3, a counterweight 4, a driving structure 5 and an industrial computer 6;

[0048] The centrifugal arm 1 is fixedly connected to the driving spindle 2 of the centrifuge, the membrane pressure sensor 3 is installed at one end of the centrifugal arm 1 , and the end of the centrifugal arm 1 away from the membrane pressure sensor 3 is provided with a drive structure 5 The groove, the counterweight 4 is installed on the centrifugal arm 1 through the driving structure 5 and the counterweight 4 can move along the length direction of the groove under the drive of the driving structure 5;

[0049] The thin film pressure sensor 3 and the counterweight 4 are respectively located on both sides of the connection between the centrifugal arm 1 and the drive spindle 2 of the centrifuge;

[0050] The industri...

Embodiment 2

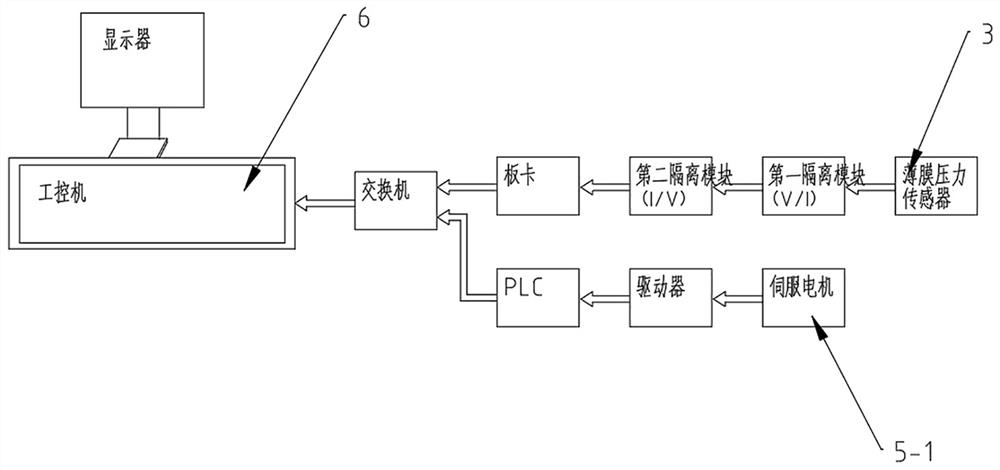

[0063] On the basis of Example 1, such as image 3 As shown, it also includes a board connected to the industrial computer 6 through a network cable, a first isolation module that converts a voltage signal into a current signal, a second isolation module that converts a current signal into a voltage signal, and a display connected to the industrial computer 6. The driver connected to the drive motor 5-1 signal, the PLC connected to the driver signal, and the switch connected to the board and PLC respectively through network cables;

[0064] The thin film pressure sensor 3 communicates with the board input terminal voltage signal through the first isolation module and the second module.

[0065] No. connection;

[0066] The board and the PLC are connected to the industrial computer 6 through a network cable through a switchboard;

[0067] The display is used to display trim data.

[0068] Specifically, the trimming data includes the weight setting of the sample, the setting ...

Embodiment 3

[0071] On the basis of Example 2, such as Figure 4 As shown, a method for automatically balancing a rotating arm centrifuge, using the described automatic balancing device for a rotating arm centrifuge, comprising the following steps:

[0072] S1: start the centrifuge and connect to the power supply;

[0073] S2: Parameter setting: set the weight of the sample and the installation radius, and display it on the display;

[0074] S3: Judging whether the weight of the sample and the counterweight are equal;

[0075] S4: When the weight of the test product > the weight of the counterweight, it is necessary to increase the operation, that is, the counterweight 4 runs towards the end away from the test product;

[0076] S5: When the weight of the test product is less than the weight of the counterweight, it is necessary to reduce the operation, that is, the counterweight 4 runs towards the end close to the test product;

[0077] S6: When the weight of the test product is equal t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com