Adaptive Ring Polishing Device for Large Aperture Aspheric Optical Components

A technology of optical components and polishing devices, which is applied in optical surface grinders, grinding/polishing equipment, grinding machines, etc., can solve the problems of complex stress disk control system, difficulty in obtaining surface shape control effects, and restrictions on the application of stress disk polishing technology. Achieve the effects of surface trimming, machining, and high-precision machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

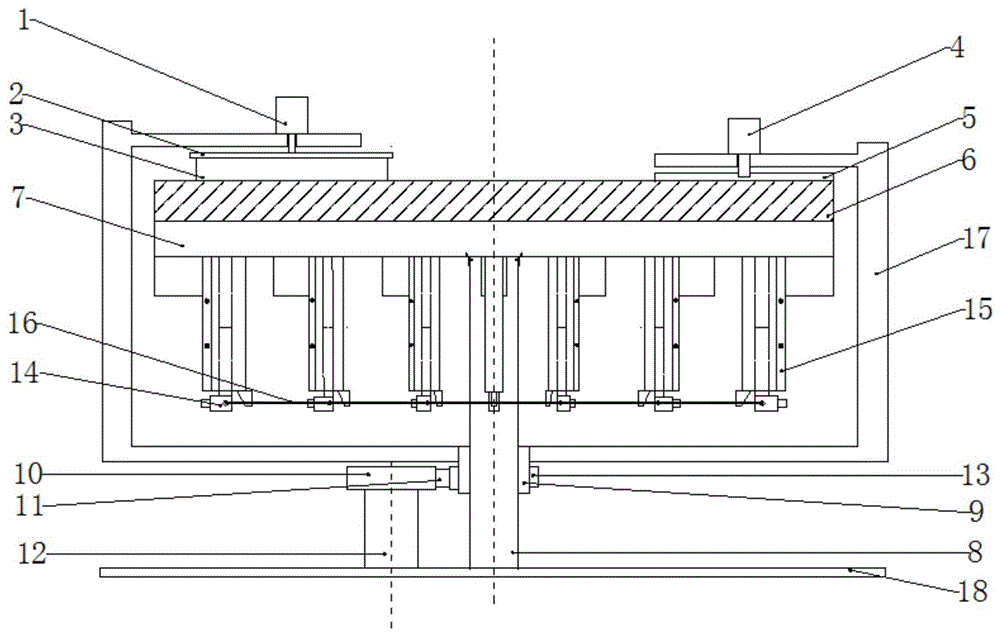

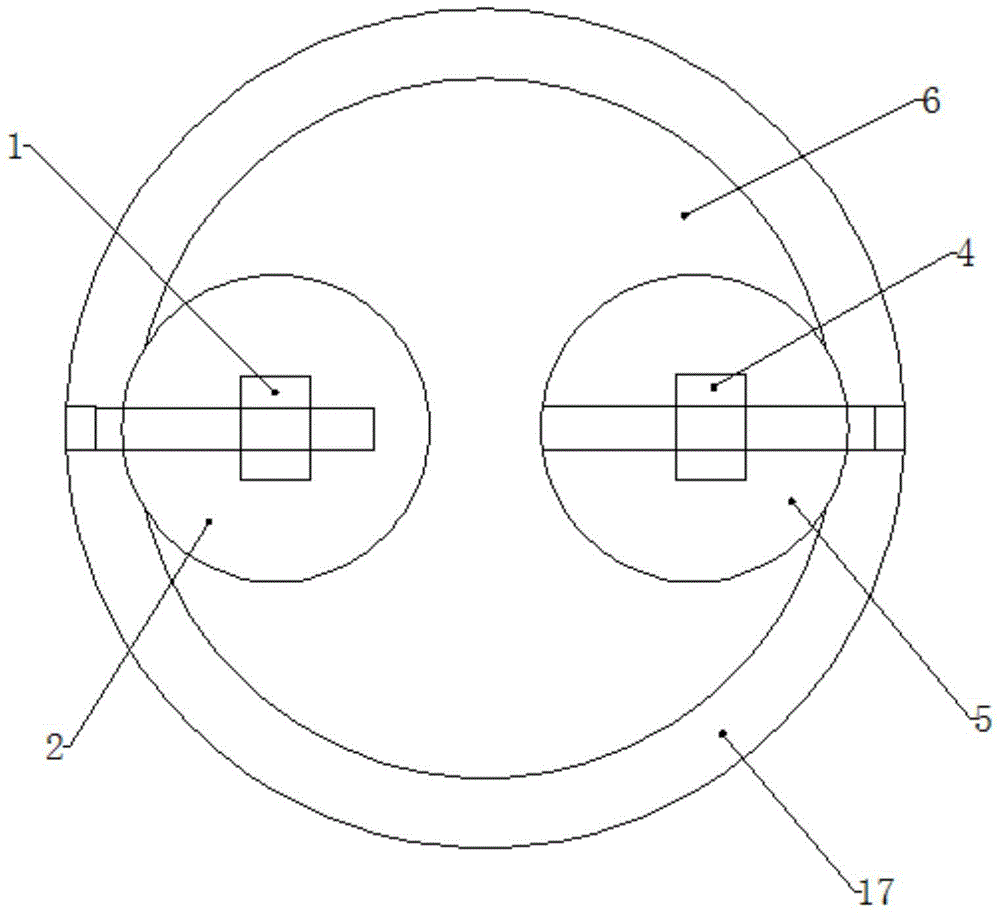

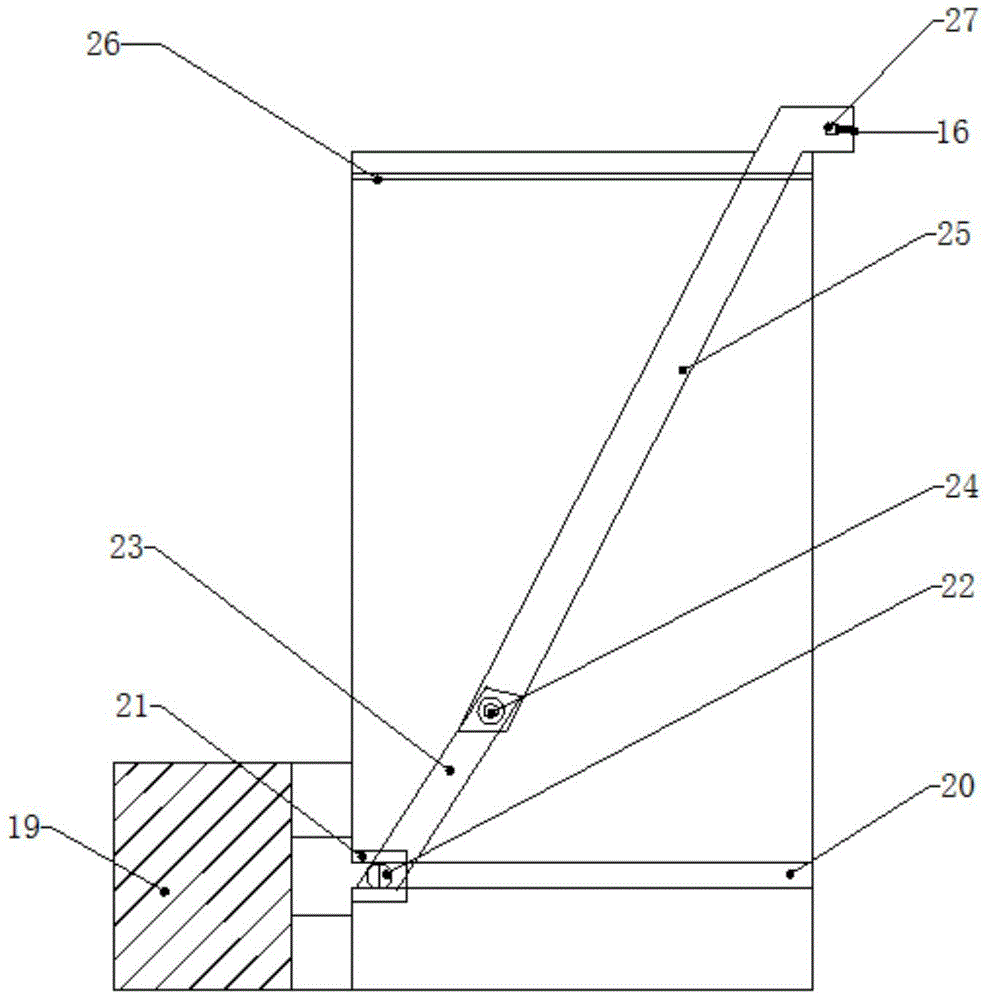

[0024] Such as figure 1 , is a schematic cross-sectional structure diagram of the self-adaptive annular polishing device for large-aperture aspheric optical elements of the present invention. Consists of workpiece motor 1, workpiece disc 2, workpiece 3, trimming motor 4, trimming disc 5, polishing die 6, active grinding disc surface 7, main shaft 8, bearing 9, main pulley 10, belt 11, rotary motor 12, slave pulley 13, Column 14, deformation driver 15, pull rope 16, bracket 17, and base 18 are composed; rotary motor 12 and main shaft 8 are respectively fixed on base 18; main pulley 10 is fixed on the rotating shaft of rotary motor 12, and bracket 17 is rotatably installed on the main shaft through bearing 9 8; the slave pulley 13 is installed on the support 17, and the slave pulley 13 and the main pulley 10 are connected by the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com