Cleaning device for steel member shot blasting

A cleaning device and a technology for steel components, which are applied to used abrasive treatment devices, cleaning methods using liquids, cleaning methods using tools, etc. The cleaning effect is not ideal and other problems, so as to reduce the probability of damaging the surface of steel components, clean comprehensively and neatly, and improve the effect of scraping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

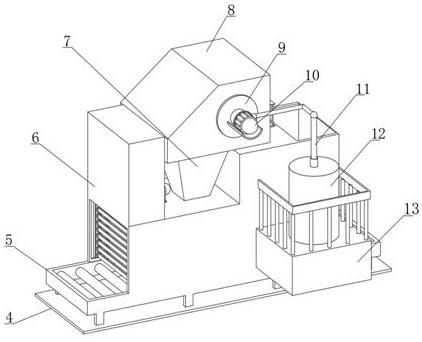

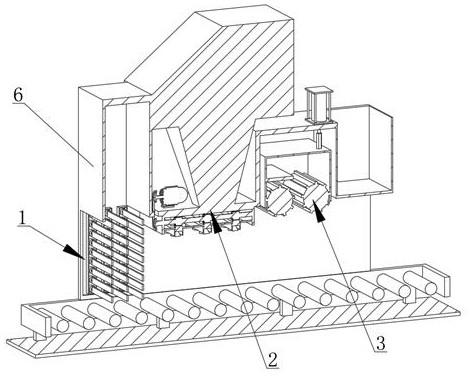

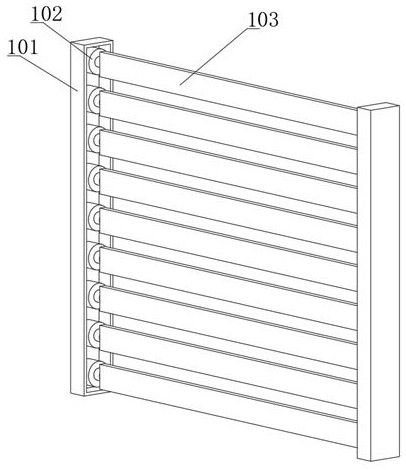

[0032] like Figures 1 to 7 As shown, a cleaning device for shot blasting of steel components includes a base plate 4, a conveyor 5 is fixedly installed on the upper surface of the base plate 4, and the upper surface of the conveyor 5 is fixedly connected with a cabinet 6, and one end of the cabinet 6 is set as an inlet and another One end is set as an outlet, and the inner wall of the cabinet 6 is sequentially installed with a scraper assembly 1, a cleaning assembly 2, and a cleaning assembly 3 from the outlet. The cleaning assembly 2 includes an installation box 204, a first motor 201, two third gears 212, and a nozzle 211. The installation box 204 is fixedly connected to the inner wall of the cabinet 6, the upper surface of the cabinet 6 is fixedly installed with the first motor 201, the output shaft of the first motor 201 is fixedly connected with the third gear 212, and the end of the other third gear 212 is fixedly connected There is a second rotating shaft 208, two thir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap