Full-automatic CCD (Charge Coupled Device) sheet alignment printing machine

A printing machine, fully automatic technology, applied to printing machines, general parts of printing machinery, printing, etc., can solve problems such as lack of protective structure, short distance between operators and printing machines, dangerous accidents, etc., to improve convenience Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

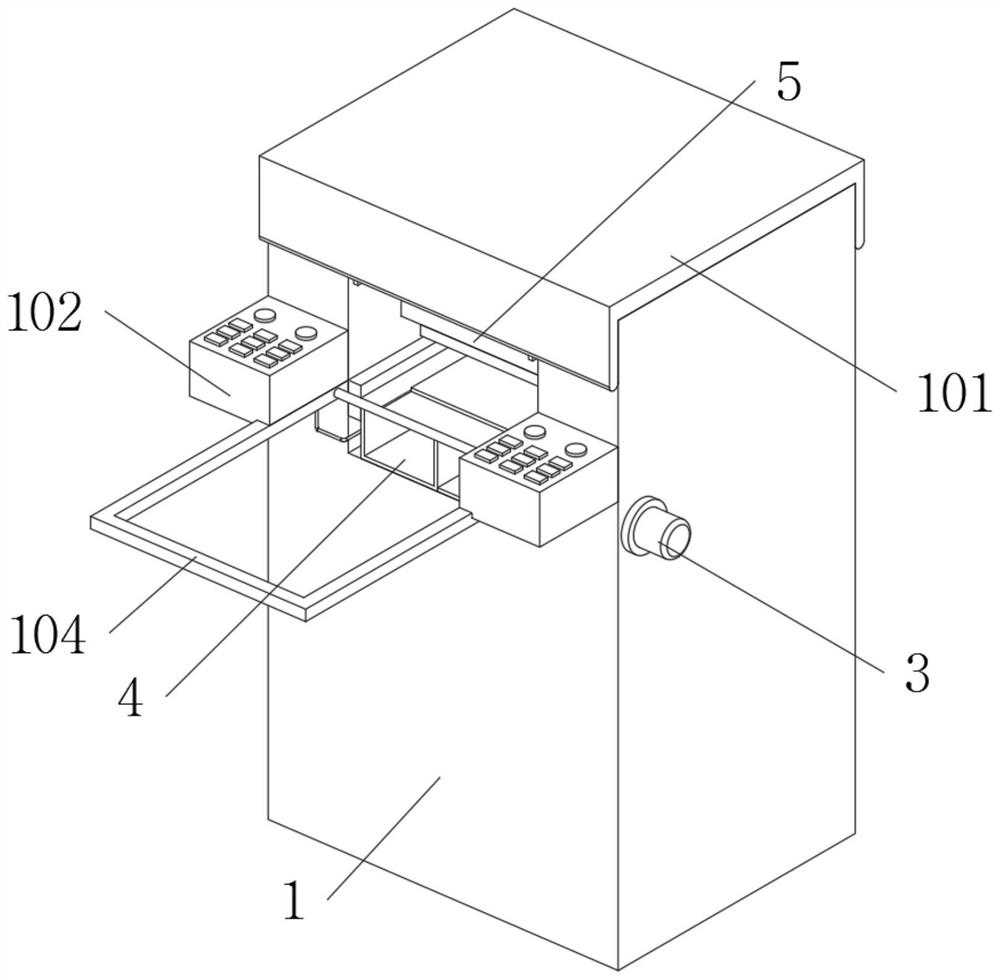

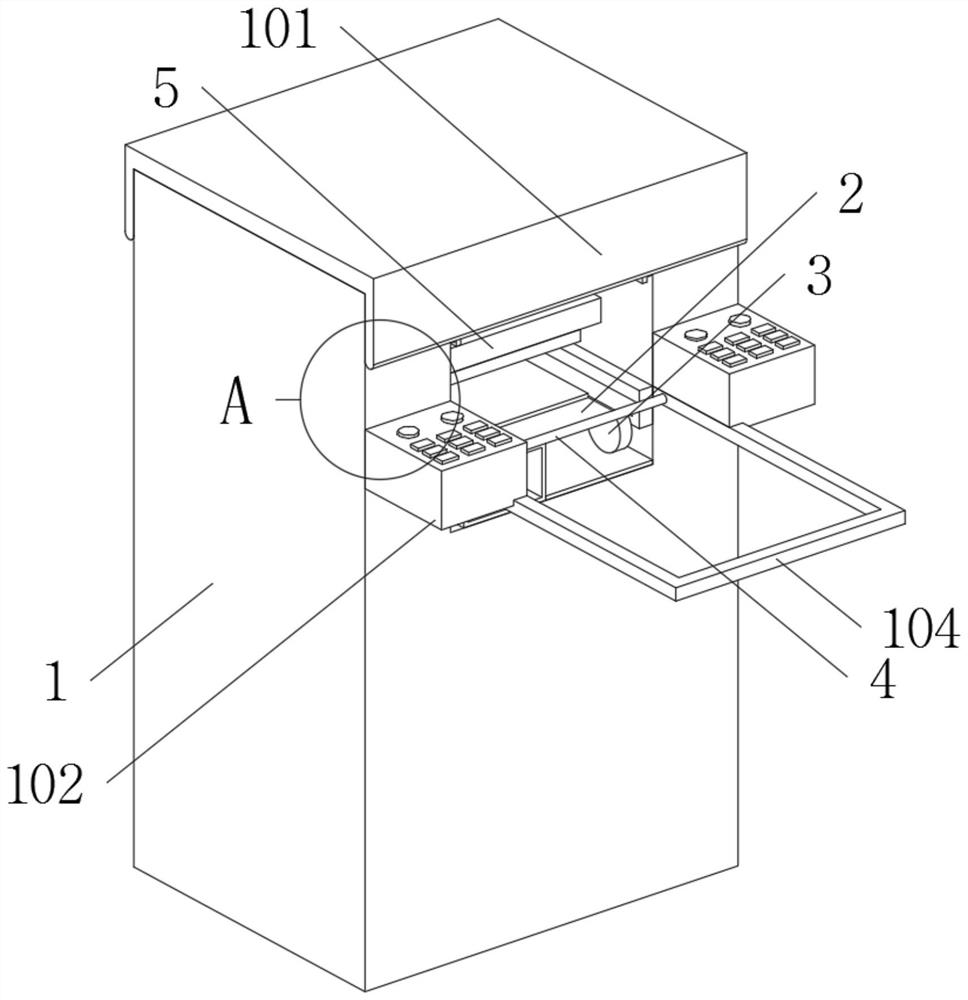

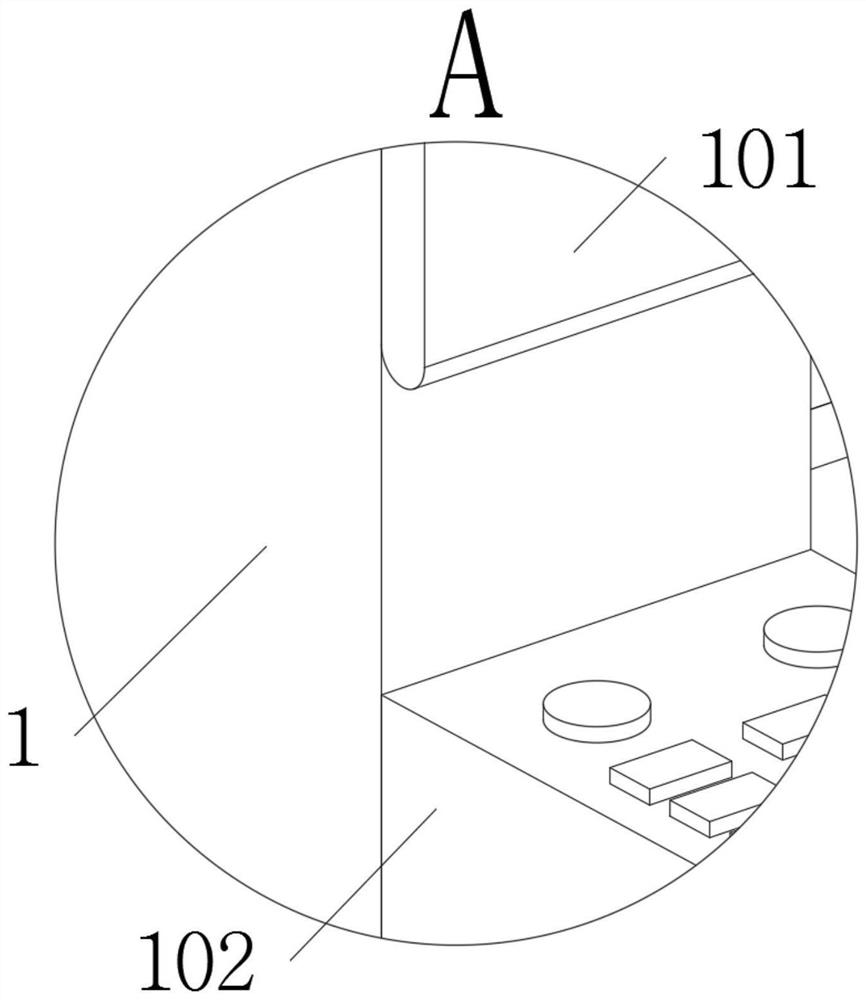

[0037] Example: Please refer to Figure 1 to Figure 8 :

[0038] The present invention proposes a fully automatic CCD sheet alignment printing machine, including: a printing machine main body 1, an adjustment unit 2, a driving unit 3, an auxiliary unit 4 and a printing unit 5;

[0039] The main body 1 of the printing machine is placed on the ground;

[0040] Adjustment part 2 is made up of slide bar 201, placement plate 202, placement groove 203, first limit plate 204 and second limit plate 205, and slide bar 201 is provided with four altogether, and four slide bars 201 are all welded on On the main body 1 of the printing machine; the four sliding rods 201 are slidably connected with a placement plate 202

[0041] The driving part 3 is composed of a driving motor 301 and a friction wheel 302, and the driving motor 301 is fixedly connected to the printing machine main body 1 by bolts;

[0042] The auxiliary part 4 is composed of an auxiliary box 401, a connecting pipe 402, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com