Gum dipping slurry, gum dipping rope head and preparation method of gum dipping rope head

A technology of slurry and dipping, which is applied in the field of clothing accessories, can solve the problems of poor effect, poor embossing effect, and difficulty in spots with three-dimensional effect, and achieves the effect of strong three-dimensional effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] In one example, the preparation method of the granular color paste includes the following steps:

[0060] Add thickener dropwise to water II to prepare pre-slurry;

[0061] Mix addition type two-component silica gel with silica gel color paste to prepare premix;

[0062] Add the premix to the pre-slurry at 1000-5000 r / min rotating speed, disperse, stand or heat to solidify to prepare the granular color paste.

[0063] In one example, the viscosity of the granular colorant is 500-3000 mPa.s.

[0064] In the present invention, since the silica gel is incompatible with the water-based glue, the dispersed silica gel droplets are suspended in the water-based glue in an approximate spherical shape under the action of surface tension. The water-based glue has a certain viscosity, which can effectively fix the silica gel droplets and prevent the silica gel droplets from converging into large droplets. The size of the powder can be achieved by controlling the stirring speed a...

Embodiment 1

[0096] This embodiment provides a red, yellow, and blue three-color embossed rubber-dipped rope head, which includes a white rope belt, and the ends of the rope belt are sequentially dip-coated with transparent background color paste, embossed three-color paste and matte Surface protection slurry with end coat length of 2cm. Its preparation steps are as follows:

[0097] (1) Take the rope

[0098] Measure a rope with a length of 100cm, cut it off for use, and make the incision tight and not loose.

[0099] (2) Oil adjustment

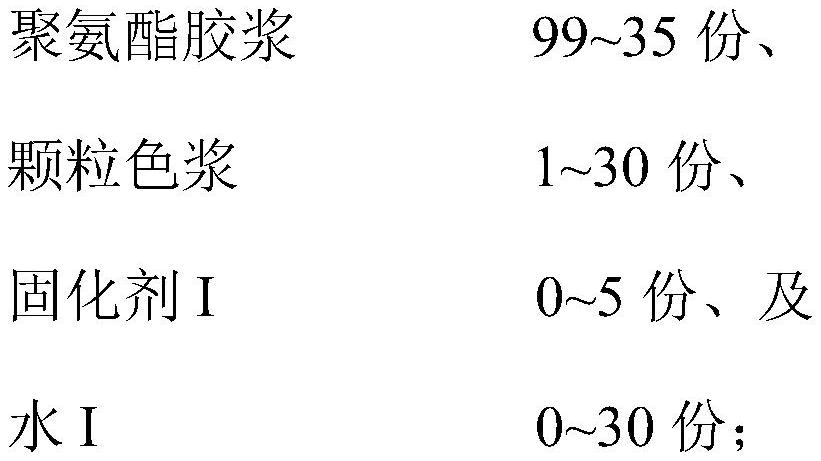

[0100] The transparent background color paste, in parts by weight, includes the following raw materials:

[0101]

[0102] Add 17 parts of water and 3 parts of carbodiimide to 80 parts of polyurethane glue, stir evenly, and obtain a slurry with a viscosity of about 1000 mPa.s, which is left to stand for defoaming;

[0103] The red granular pulp, in parts by weight, includes the following raw materials:

[0104]

[0105] Weigh 80 parts of water...

Embodiment 2

[0122] This embodiment provides a two-color embossed rubber-dipped rope head, which includes a white rope belt. The ends of the rope belt are sequentially dip-coated with black background color paste, embossed two-color paste and bright surface protection paste. The layer length is 2cm. Its preparation steps are as follows:

[0123] (1) Take the rope

[0124] Measure a rope with a length of 100cm, cut it off for use, and make the incision tight and not loose.

[0125] (2) Oil adjustment

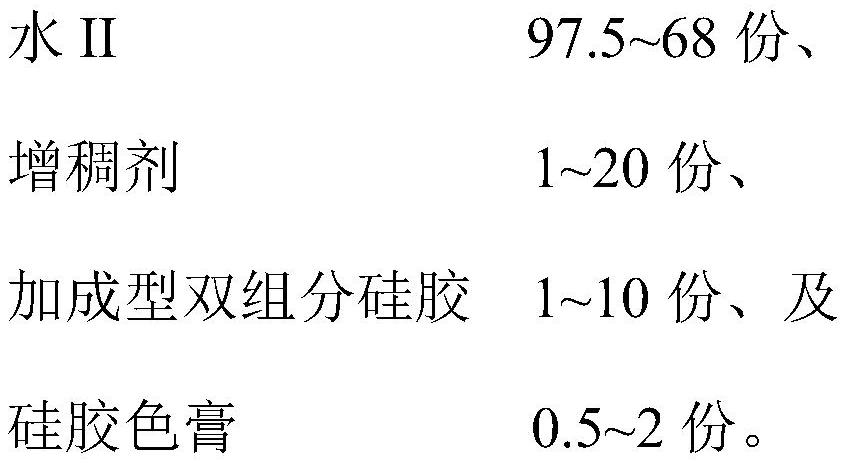

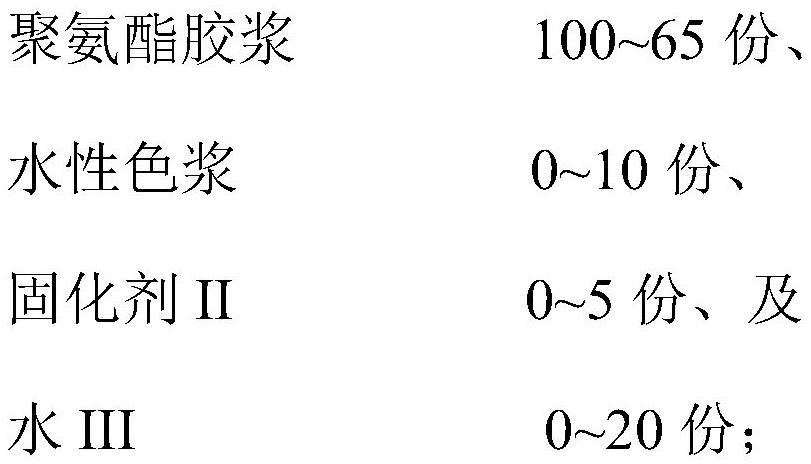

[0126] The black background color paste, in parts by weight, includes the following raw materials:

[0127]

[0128] Add 5 parts of black water-based color paste, 17 parts of water and 1 part of water-based isocyanate to 77 parts of polyurethane glue, stir evenly to obtain a slurry with a viscosity of about 800 mPa.s, and let it stand for defoaming for later use;

[0129] The silver granule pulp, in parts by weight, includes the following raw materials:

[0130]

[0131] Weigh 84.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com