Water-based painting pigment with strong stereoscopic impression

A three-dimensional, water-based technology, applied in polyester coatings, art coatings, polyurea/polyurethane coatings, etc., can solve problems such as easy color crossing, color mixing, affecting painting effects, and difficulty in ensuring clean and clear three-dimensional pictures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

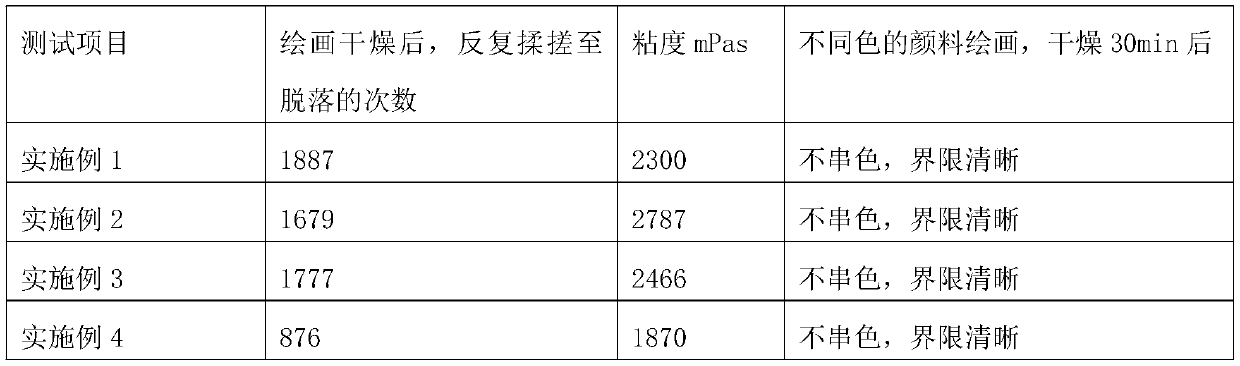

Examples

Embodiment 1

[0014] Mix 40 parts of acrylic emulsion, 60 parts of water-based resin, and 0.7 parts of silane coupling agent, heat to 40°C, and obtain solution A after cooling; mix 15 parts of water-based polyvinyl acetate, 7 parts of gelatin, 8 parts of alginate, Mix 55 parts of water, heat to 90°C, stir evenly, and obtain solution B after cooling; after mixing solution A and solution B, add 1 part of propylene glycol, 25 parts of pigment, 0.6 part of dispersant, and 15 parts of filler, and heat to Stir evenly at 45°C to obtain water-based paint with strong three-dimensional effect.

[0015] The pigments are organic pigments of various colors; the dispersant can be sodium methylene dinaphthalene sulfonate; the filler can be calcium carbonate; the water-based resin can be water-based alkyd.

Embodiment 2

[0017] Mix 50 parts of acrylic emulsion, 30 parts of water-based resin, and 0.3 parts of silane coupling agent, heat to 45°C, and obtain solution A after cooling; mix 30 parts of water-based polyvinyl acetate, 12 parts of gelatin, 6 parts of alginate, Mix 50 parts of water, heat to 80°C, stir evenly, and obtain solution B after cooling; after mixing solution A and solution B, add 1 part of propylene glycol, 25 parts of pigment, 0.6 part of dispersant, and 15 parts of filler, and heat to Stir evenly at 55°C to obtain water-based paint with strong three-dimensional effect.

[0018] The pigment is an inorganic pigment; the dispersant can choose DISPERBYK-190; the filler can choose kaolin; the water-based resin can choose water-based polyurethane.

Embodiment 3

[0020] Mix 45 parts of acrylic emulsion, 45 parts of water-based resin, and 0.5 parts of silane coupling agent, heat to 42°C, and obtain solution A after cooling; mix 23 parts of water-based polyvinyl acetate, 10 parts of gelatin, 7 parts of alginate, Mix 52 parts of water, heat to 85°C, stir evenly, and obtain solution B after cooling; after mixing solution A and solution B, add 1.5 parts of propylene glycol, 27 parts of pigment, 0.4 parts of dispersant, and 23 parts of filler, and heat to Stir evenly at 50°C to obtain water-based paint with strong three-dimensional effect.

[0021] The pigment is a mixture of organic pigments and inorganic pigments of various colors; the dispersant is a mixture of sodium methylene dinaphthalene sulfonate and DISPERBYK-190, and the weight ratio of sodium methylene dinaphthalene sulfonate and DISPERBYK-190 is 1:1 The filler is a mixture of calcium carbonate and kaolin, the weight ratio of calcium carbonate and kaolin is 2:1; the water-based re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com