Bailey bracket of cast-in-place box girder and construction method of Bailey bracket

A technology of cast-in-place boxes and support rods, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as low safety factor and insufficient support strength, achieve strong connection stability, improve support effect, and increase support strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

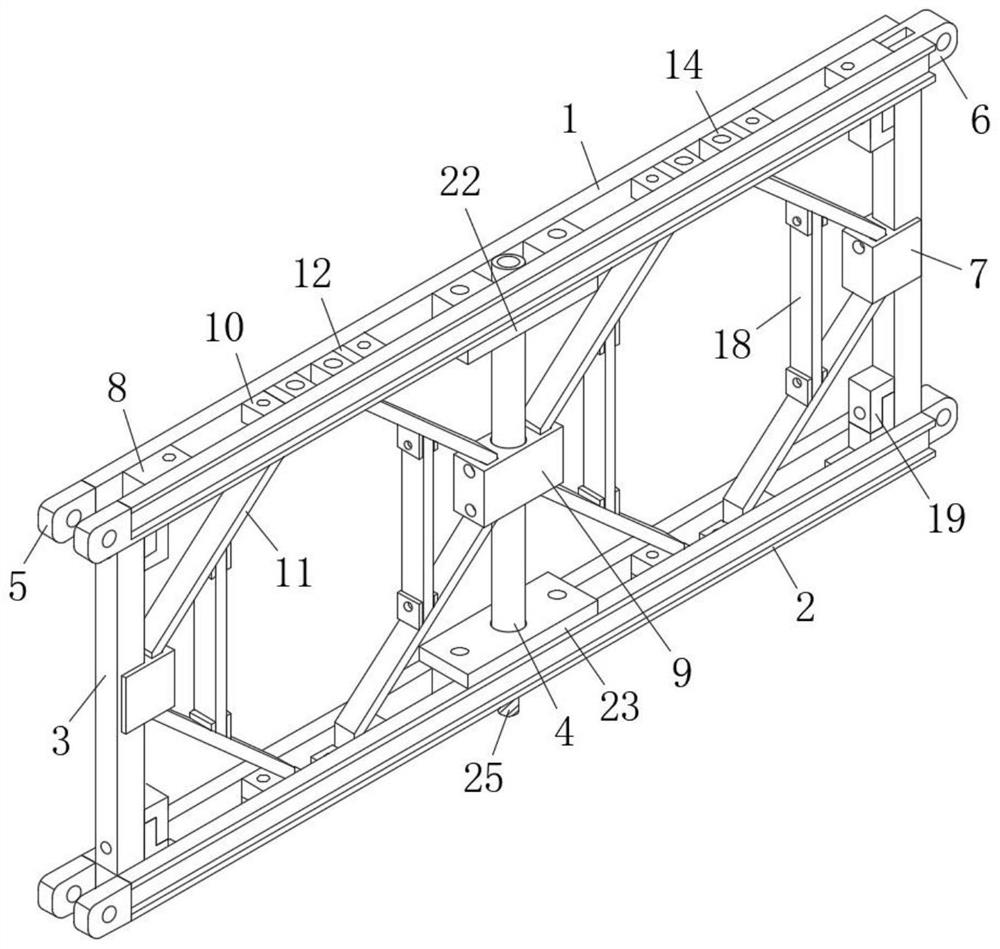

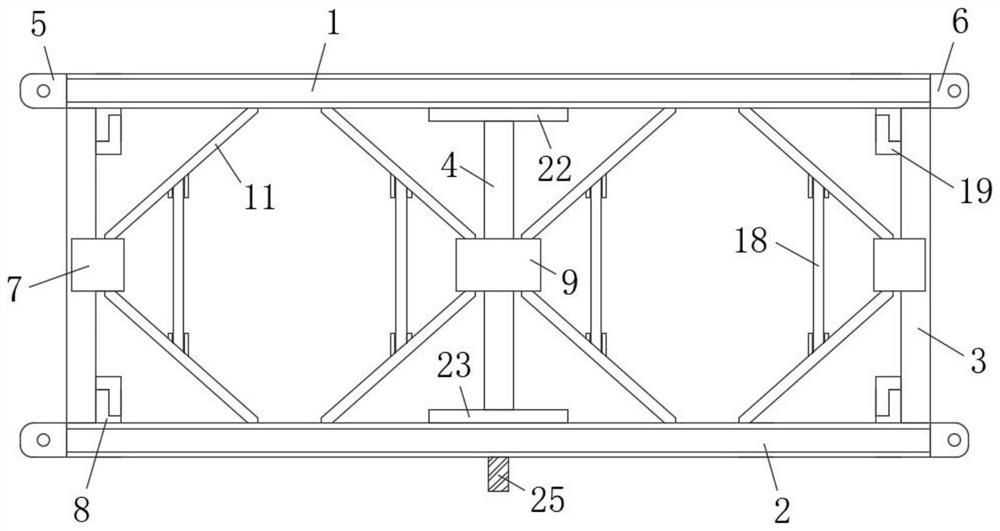

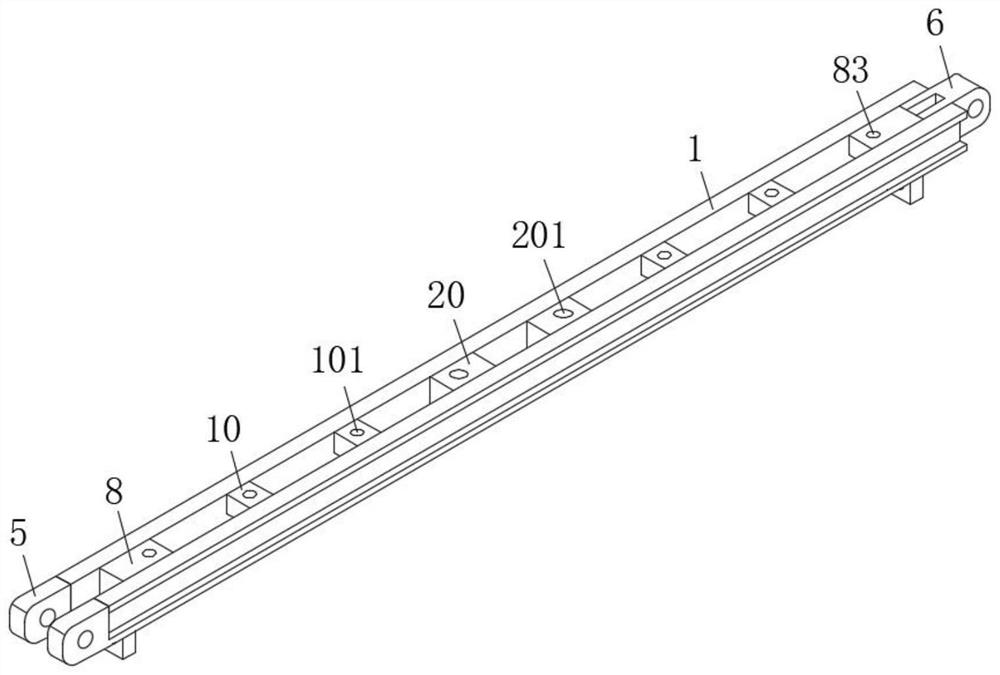

[0055] refer to Figure 1-12 , a Bailey support for cast-in-place box girders, including an upper chord 1 and a lower chord 2, two vertical rods 3 are symmetrically arranged between the upper chord 1 and the lower chord 2, and the two ends of the upper chord 1 and the lower chord 2 are A female head 5 and a male head 6 for docking are provided respectively, a fixed block 7 is fixedly welded on the sides of the two vertical bars 3 close to each other, and the same support bar 4 is fixedly connected between the upper chord 1 and the lower chord 2 , And the support bar 4 is located between the two vertical bars 3, one side of the support bar 4 is rotatably provided with a fixed ring 9, the top and bottom of the two fixed blocks 7 and the top and bottom sides of the fixed ring 9 are all fixed. Diagonal struts 11 are connected, and the tops of the upper diagonal struts 11 are fixedly connected with the upper chord 1 , and the bottom ends of the lower diagonal struts 11 are all fixe...

Embodiment 2

[0062] This embodiment is as a further improvement of the previous embodiment: refer to Figure 1-12 , a Bailey support for cast-in-place box girders, including an upper chord 1 and a lower chord 2, two vertical rods 3 are symmetrically arranged between the upper chord 1 and the lower chord 2, and the two ends of the upper chord 1 and the lower chord 2 are A female head 5 and a male head 6 for docking are provided respectively, a fixed block 7 is fixedly welded on the sides of the two vertical bars 3 close to each other, and the same support bar 4 is fixedly connected between the upper chord 1 and the lower chord 2 , And the support bar 4 is located between the two vertical bars 3, one side of the support bar 4 is rotatably provided with a fixed ring 9, the top and bottom of the two fixed blocks 7 and the top and bottom sides of the fixed ring 9 are all fixed. Diagonal struts 11 are connected, and the tops of the multiple diagonal struts 11 located above are all fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com