A building continuous assembly method and prefabricated building that can avoid wall deflection

An assembly method and assembly technology, which is applied in the direction of buildings, building components, building reinforcements, etc., can solve the problems of deflection of prefabricated walls, insufficient grouting materials, etc., and achieve the effect of shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

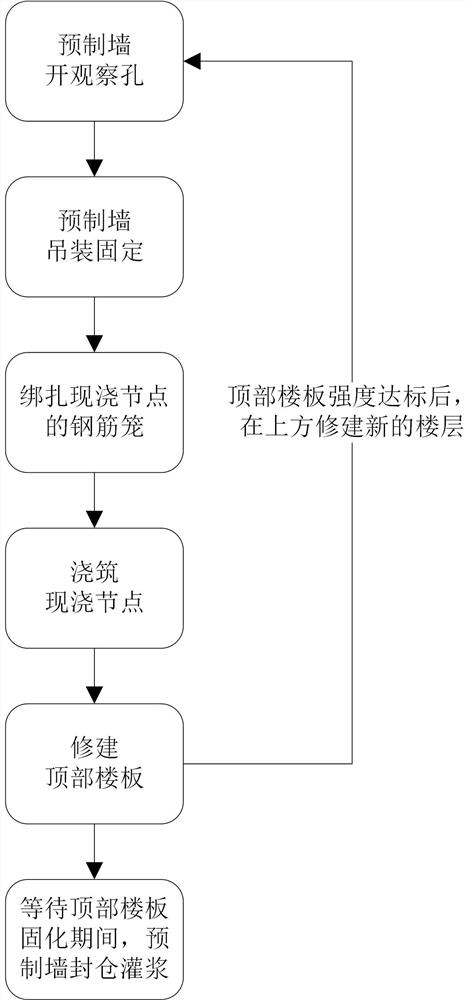

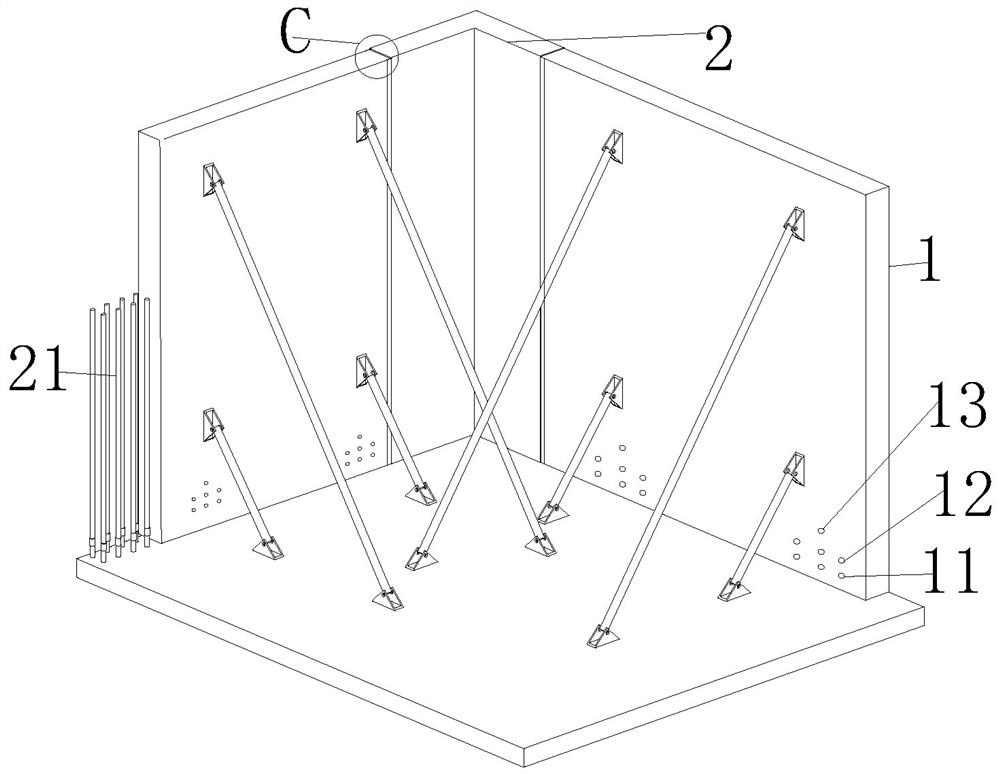

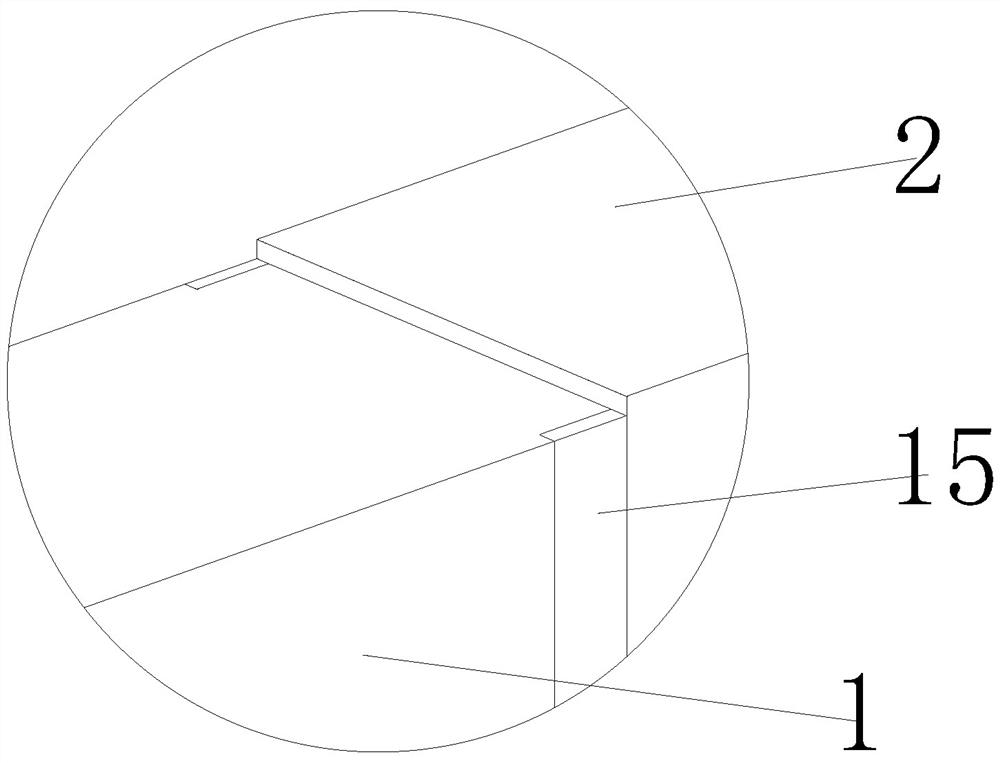

[0035] like figure 1 As shown in the figure, a continuous building assembly method that can avoid the deflection of the wall is used to construct a prefabricated building by using a prefabricated wall 1. The steel bars at the bottom of the prefabricated wall 1 are connected with the reserved steel bars on the base surface through a grouting sleeve, and the prefabricated wall 1 is connected with the reserved steel bars on the base surface. 1. The bottom is provided with a grouting silo, a grouting hole 11 communicating with the grouting silo, and a grouting hole 12 higher than the grouting hole 11 and communicating with the grouting sleeve of the grouting sleeve. The grouting sleeve is arranged in the grouting silo, and The opening at the bottom is communicated with the grouting bin; the adjacent prefabricated walls 1 are connected through cast-in-place nodes 2, and the floor slab of the prefabricated building is a laminated slab; the assembly method includes the following steps...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com