Fabricated building wall and fabricated building

A building wall and assembly technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of poor waterproof performance, easy water seepage to the inside, and affect user experience, etc., with little possibility of achieving, good waterproof effect, Avoid the effect of rain dripping and splashing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

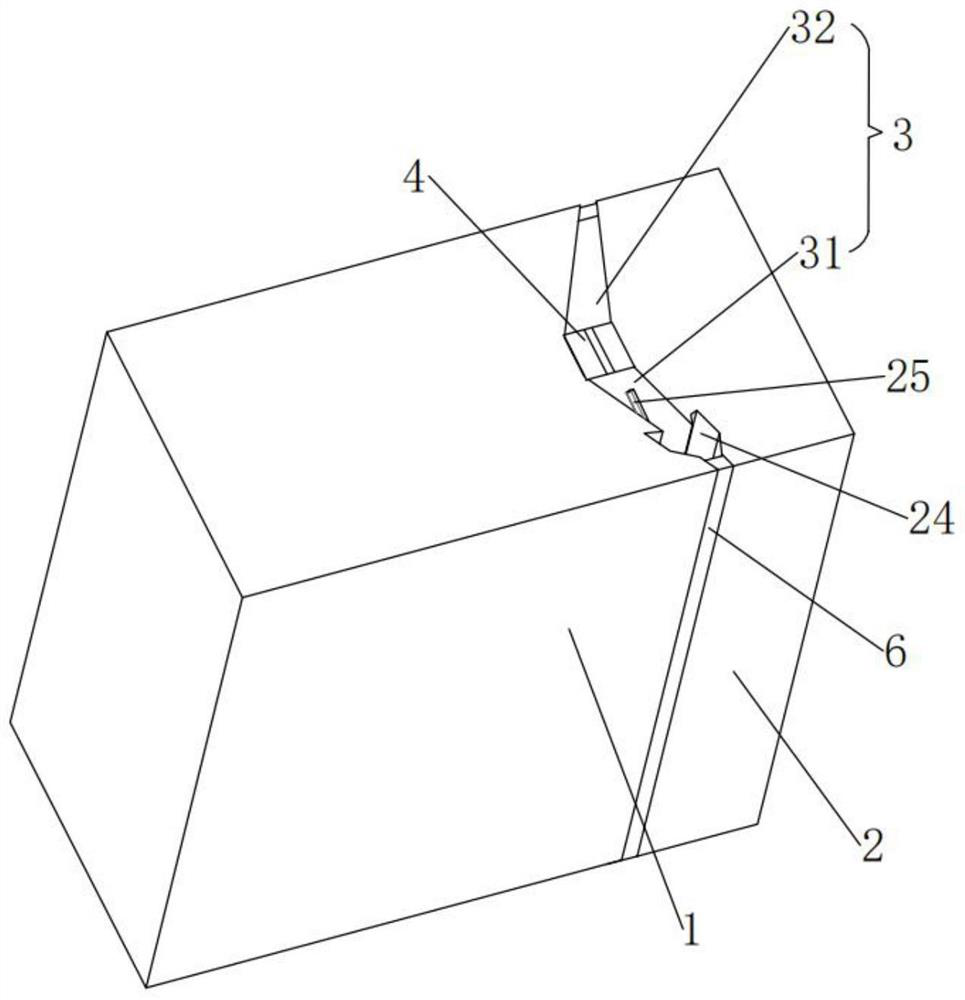

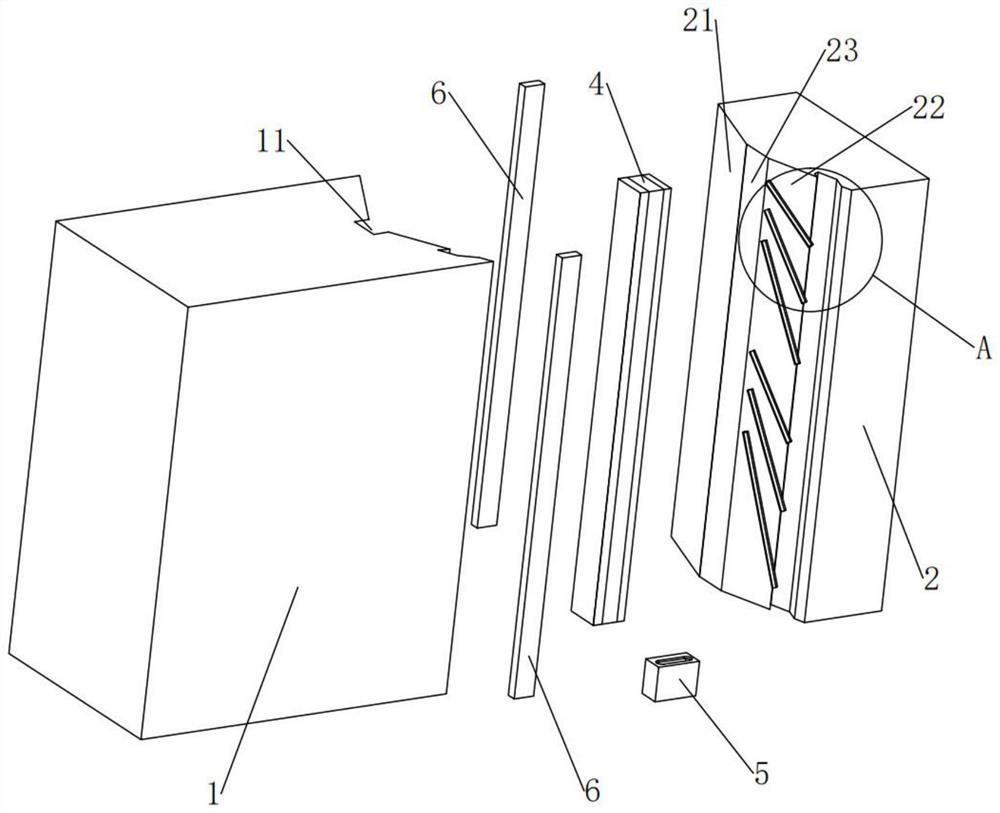

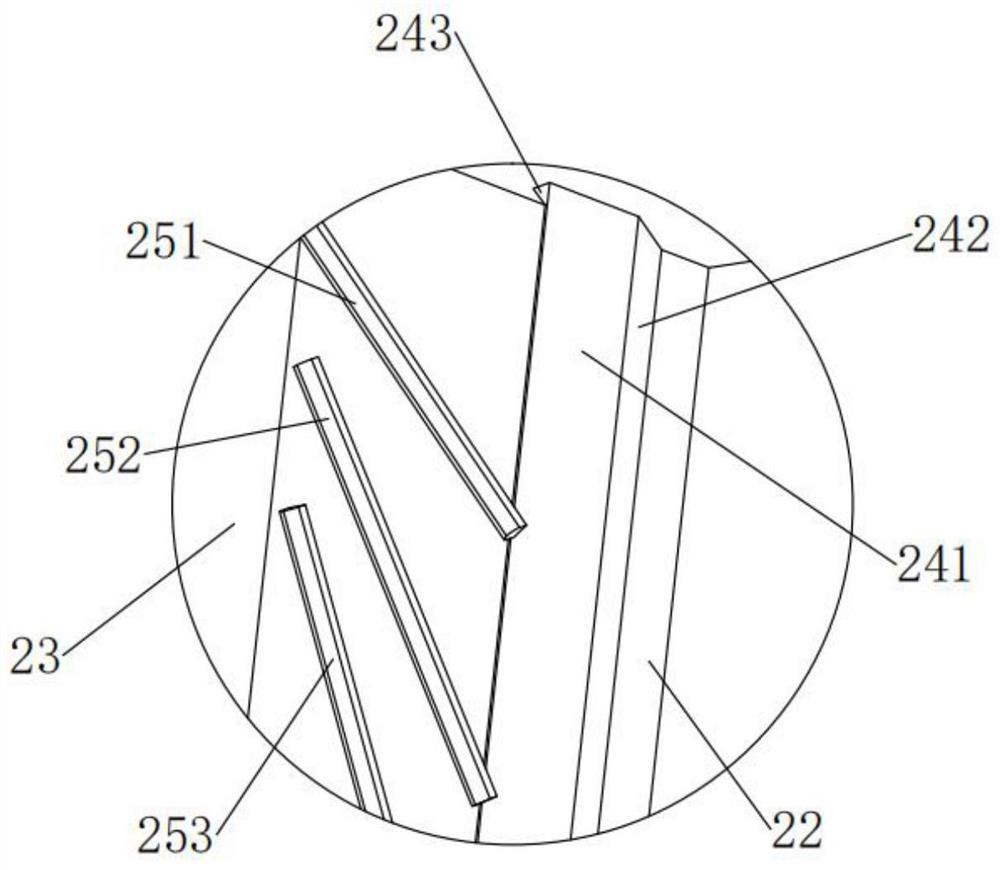

[0041] Such as Figure 1-2 As shown, a prefabricated building wall includes a first wall 1 and a second wall 2, and a substantially V-shaped vertical joint is formed between the first wall 1 and the second wall 2 3. The first sealing member 4 is arranged in the vertical joint 3, and the two sides of the first sealing member 4 are respectively provided with a sealing strip 6, and the first sealing member 4 and the sealing strip 6 connect the vertical joint Seam 3 is divided into drainage space 31, water blocking space 32,. This setting combines drainage and water blocking, the first sealing member 4 plays an effective hydrophobic role, and the drainage space 31 and the water blocking space 32 perform drainage and water blocking respectively, effectively reducing the phenomenon of water accumulation and water seepage in the wall of the prefabricated building , good waterproof effect. Both the sealing strip 6 and the first sealing member 4 are made of elastic materials, the spe...

Embodiment 2

[0056] The present invention also provides an assembly process for a prefabricated building, comprising the following steps:

[0057] S1. Pouring ground beams on the ground, the ground beams are provided with embedded parts, and the top ends of the ground beams are provided with grooves;

[0058] Preferably, the embedded part is composed of a flat plate and steel bars evenly distributed at the bottom of the flat plate, the steel bars are pre-embedded in the ground beam, and the flat plate is exposed at the groove on the top of the ground beam. As an example of the present invention, the steel bar on the embedded part is a hook steel bar with a hook-shaped bottom end.

[0059] S2. Fit the first sealing member 4 into the assembly groove 11, connect and fix the first wall 1 and the second wall 2 with the ground beam through the fixing piece, and form a vertical connection between the first wall 1 and the second wall 2 Seam 3; the width of the vertical seam is 10-15mm, the height...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com