Hollow breathable glass partition with built-in roller shutter

A hollow, glass technology, used in door/window protection devices, building components, dispersed particle filtration, etc., can solve the problems of endangering the health of participants, lack of air circulation, and fainting of participants, and achieve good economic and social benefits. , the effect of reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

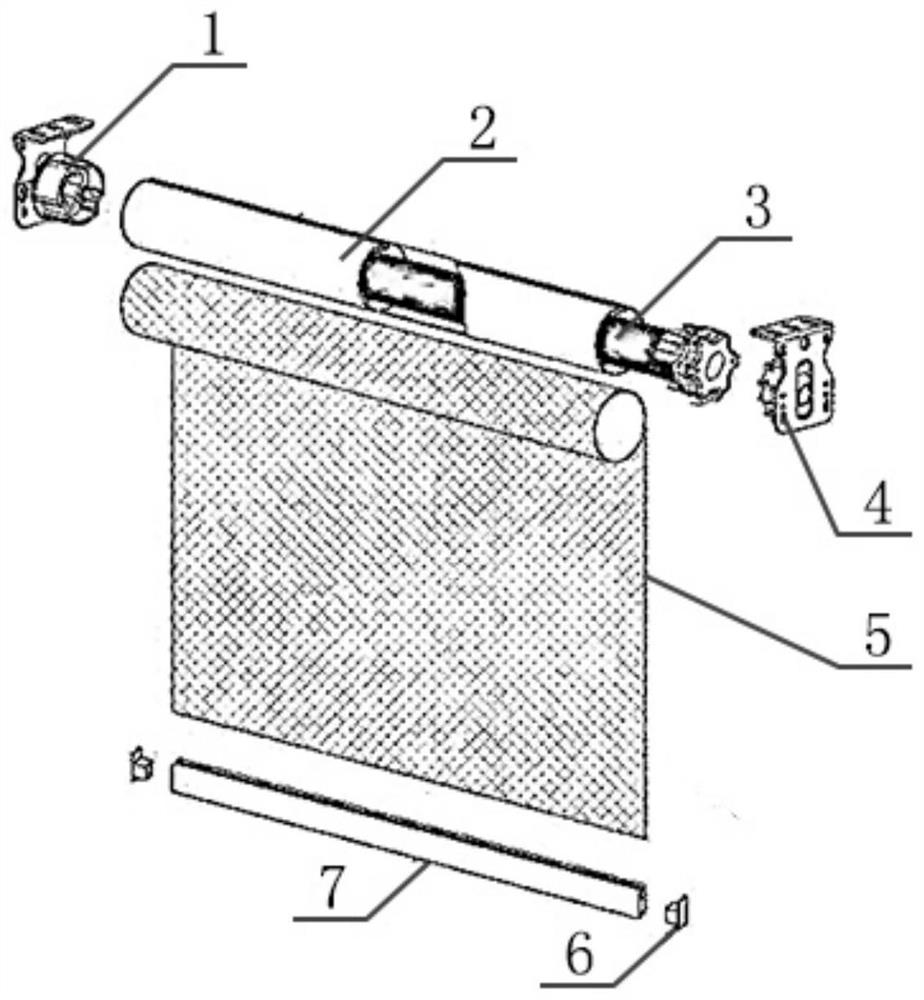

[0034] Embodiment 1. The present invention provides a hollow air-permeable glass partition with a built-in roller blind.

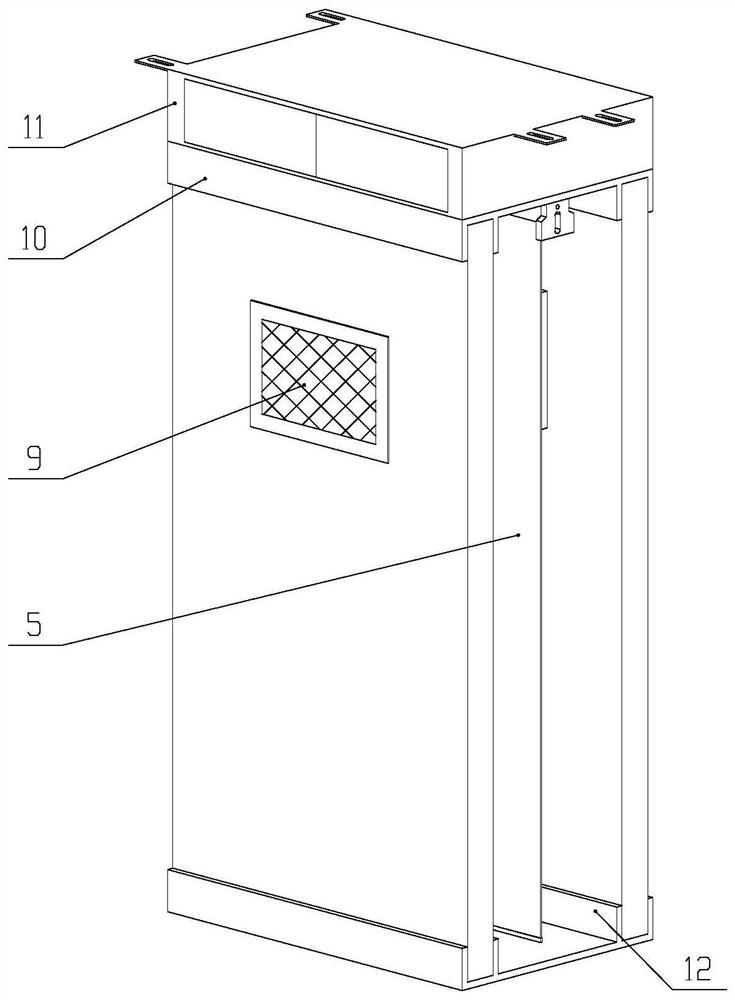

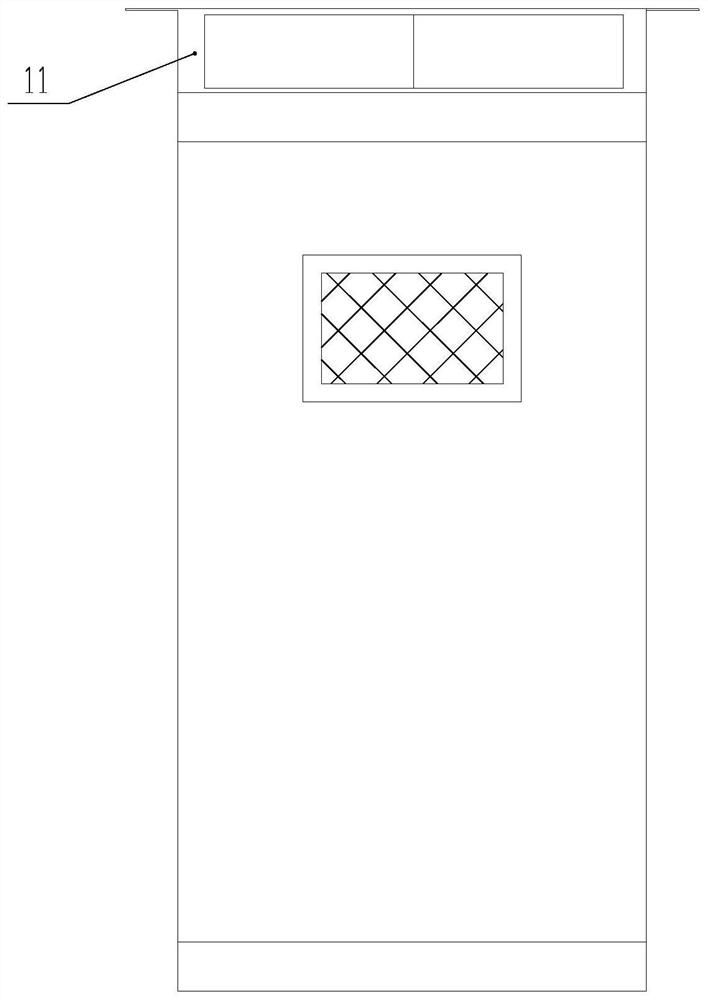

[0035] Such as figure 2 As shown, it includes an upper profile 10 and a lower profile 12 located on the same vertical plane, and two parallel insulating glasses are arranged between the upper profile 10 and the lower profile 12,

[0036] Such as Figure 5 As shown, vent holes 8 are provided on the upper part of any one insulating glass, and filter windows 9 are provided on the end faces of the two insulating glasses that are far away from each other, and the filter windows 9 are all installed on the vent holes 8 of the insulating glass on one side, The filter window 9 is provided with a filter element adopting filter paper or non-woven material;

[0037] Opening and closing devices are installed on the adjacent end faces of the two insulating glasses;

[0038] Ventilation can be realized when the two opening and closing devices are opened at the same t...

Embodiment 2

[0050] Embodiment two, installation and use of the present invention:

[0051] Such as Figure 8 As shown, when two pieces of breathable glass partitions are installed, the first mounting plate of the first breathable glass partition shell and the second mounting plate of the second breathable glass partition shell are installed on the same side, and the first breathable glass partition and the second breathable glass partition Aluminum alloy profiles 16 with outer inlays are installed between the glass partitions.

[0052] During specific implementation, the rolling cloth 5 of the electric roller blind uses mesh cloth, and runs up and down through the rotation of the first aluminum alloy rolling tube 2, which plays the role of sunshade and heat insulation, light adjustment, decoration and beautification; the second tubular motor passes through the first The rotation of the two aluminum alloy roll pipes 15 moves up and down to realize the ventilation of the glass partition. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com