Angular contact self-aligning roller bearing

A self-aligning roller bearing and angular contact technology, used in rolling contact bearings, bearings, bearing components, etc., can solve the problems of bearing failure, single-row rolling element bearing, small axial load, etc., and achieve the effect of improving bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

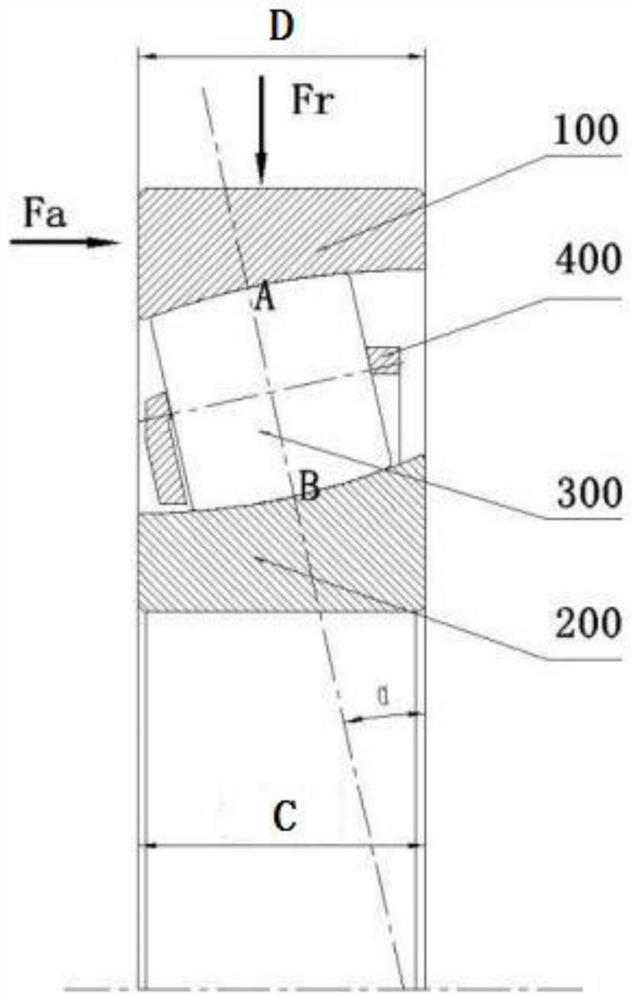

[0044] refer to Figure 1-Figure 4 and Figure 9-Figure 10 , as a preferred embodiment, Embodiment 1 of this embodiment provides an angular contact spherical roller bearing. Embodiment 1 further includes the following technical features:

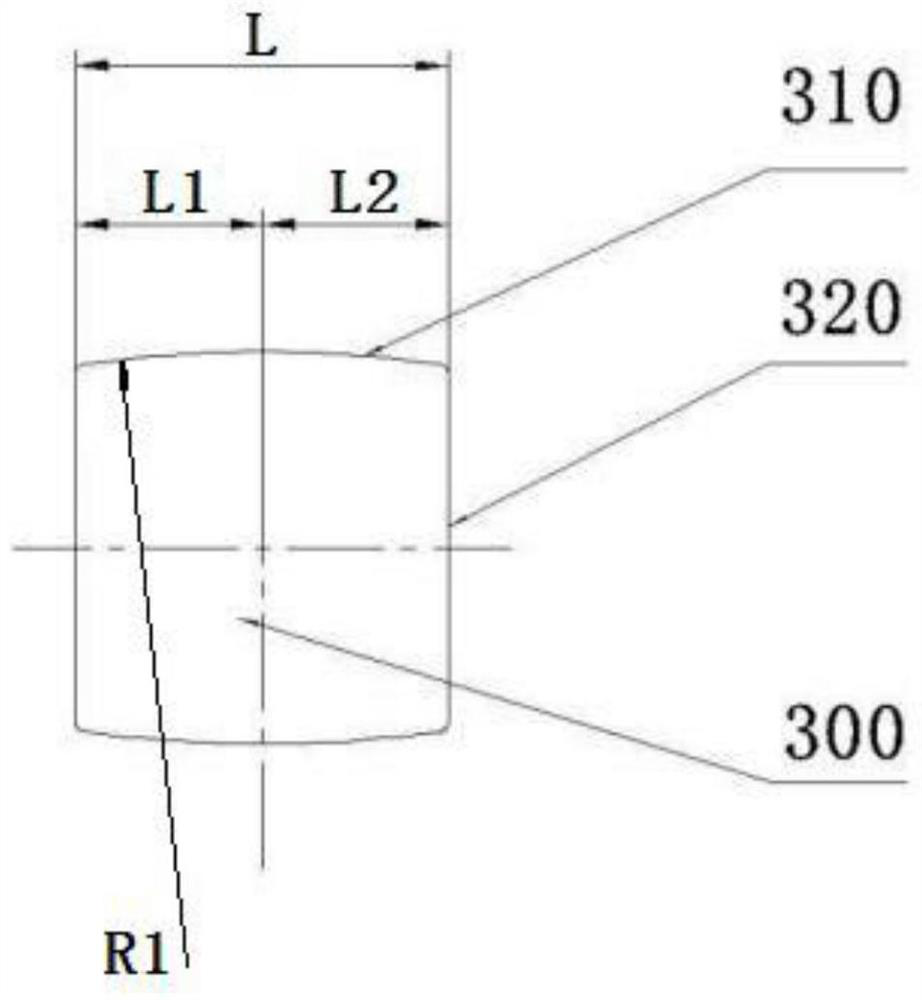

[0045] Taking the axial length of the roller 300 as L, the distance from the center of the first arc to the first axial end of the roller 300 is L1, and the distance from the center of the first arc to the second end of the roller 300 in the axial direction The distance is L2, L1=L2=L / 2. The normal of the outer raceway 110 at point A passes through point B, and the normal of the inner raceway 210 at point B passes through point A. That is, α=β, the forces exerted by the inner raceway 210 and the outer raceway 110 on the roller 300 are collinear and opposite in direction, and these two forces can cancel each other out (gravity is ignored), so there is no need to set up additional limiting structures (such as Rib) limits the roller 300, an...

Embodiment 2

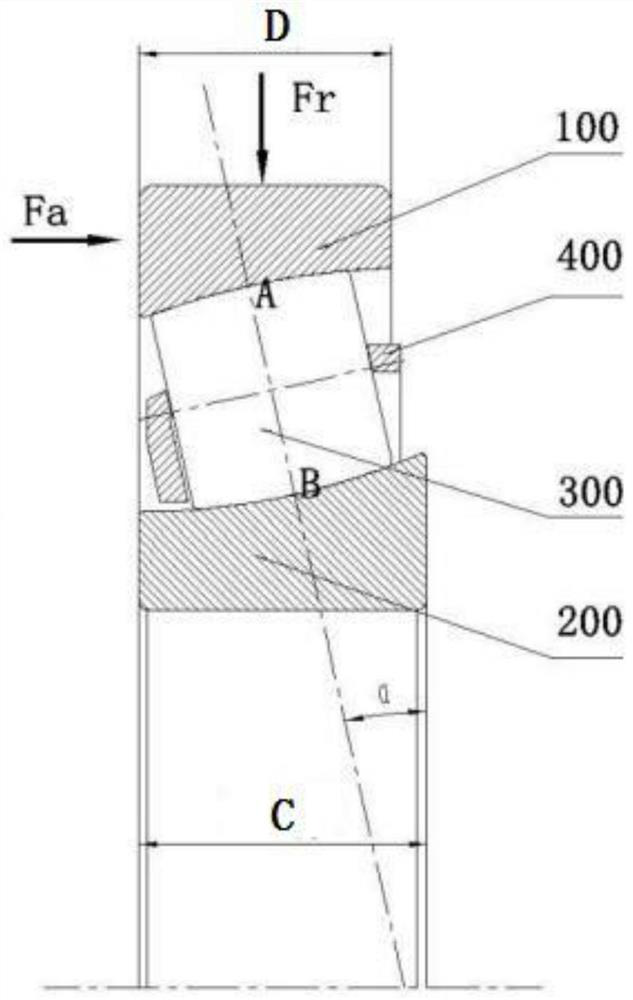

[0049] refer to Figure 5-Figure 8 and Figure 9-Figure 10 , as yet another preferred embodiment, Embodiment 2 of this embodiment provides an angular contact spherical roller bearing. Embodiment 2 further includes the following technical features:

[0050] Taking the axial length of the roller 300 as L, the distance from the center of the first arc to the first axial end of the roller 300 is L1, and the distance from the center of the first arc to the second end of the roller 300 in the axial direction The distance is L2, then L1>L / 2>L2. β<α, that is, the forces exerted by the inner raceway 210 and the outer raceway 110 on the roller 300 are not collinear, and the two cannot cancel (ignoring gravity). A rib is provided on the inner ring 200 , and the rib contacts with the second axial end of the roller 300 to balance the resultant force exerted by the inner raceway 210 and the outer raceway 110 on the roller 300 . When in use, the roller 300 is always in contact with the r...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap