Cast-in-place pile hole bottom sediment thickness detecting and reinforcing device and construction method thereof

A technology of slag thickness and reinforcement device, applied in measuring devices, instruments, etc., can solve the problems of vertical compressive bearing capacity of cast-in-place piles and adverse effects of settlement, and achieve the effect of thorough slag treatment and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to understand the technical features, objects and effects of the present invention, specific embodiments of the present invention will be described in detail with reference to the accompanying drawings.

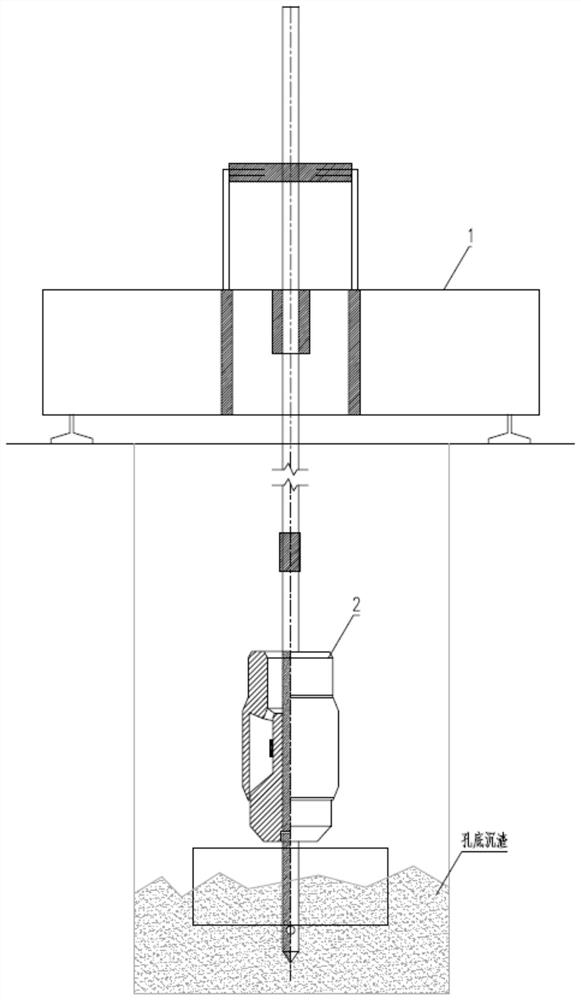

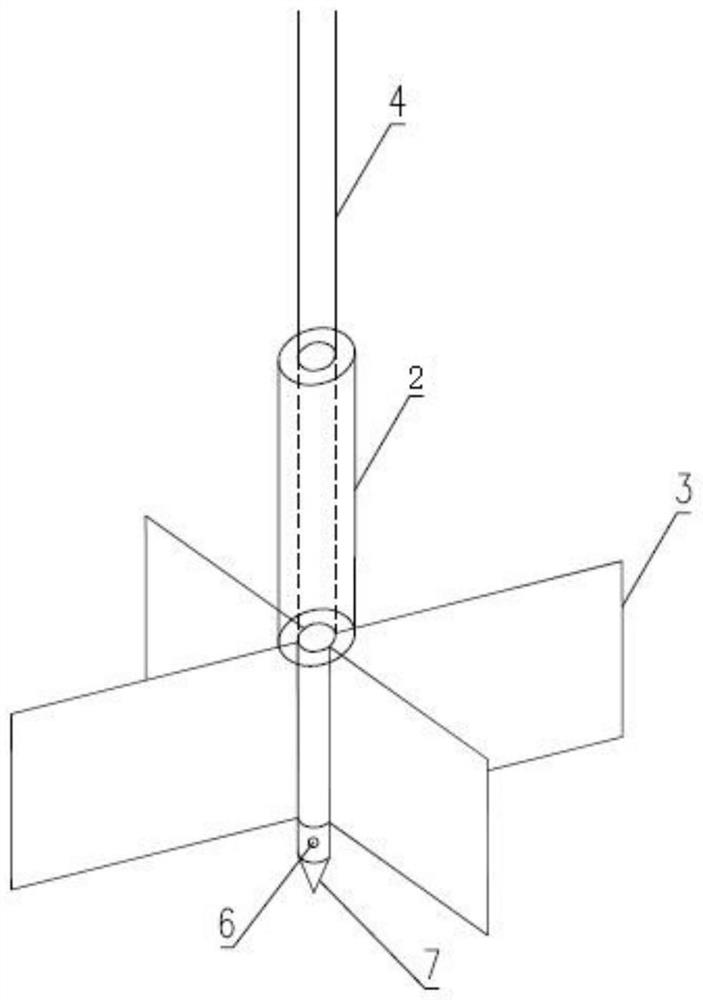

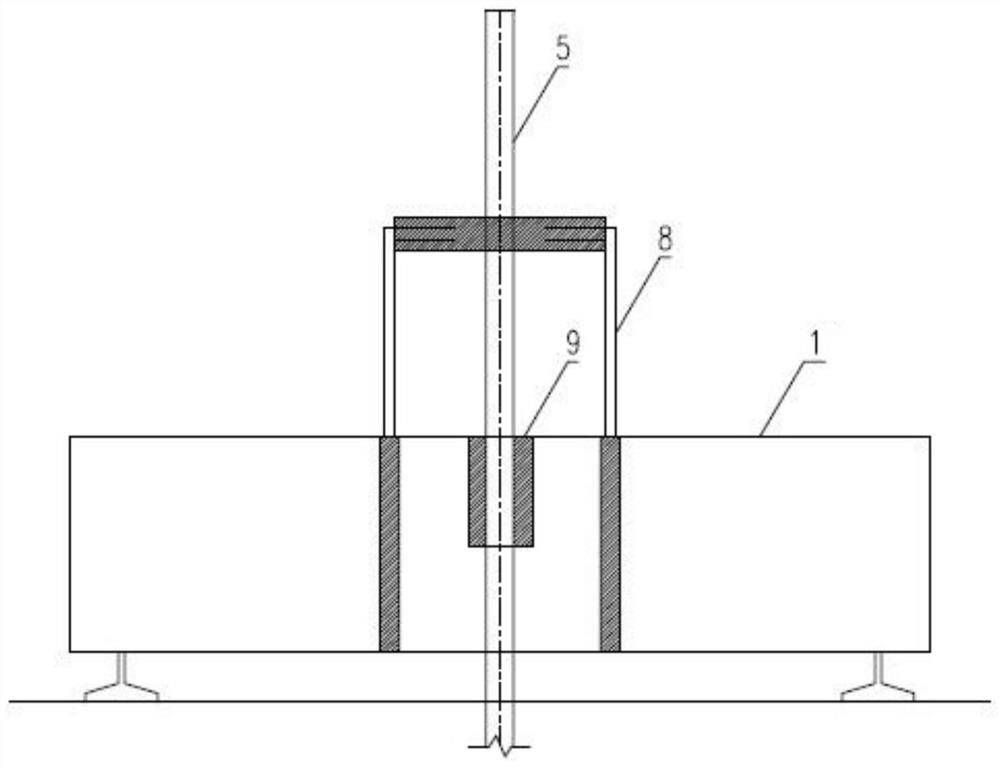

[0025] Such as Figure 1-5 As shown, the inventive thickness detecting reinforcement means including a base 1, a lifting platform 8, a rotating power device, a push rod 5, a grouting pump, and a probe 4, a lifting platform 8 and a rotating power device mounted on a base 1, the lifting platform 8 drives the push rod 5 lifting, the rotary power device drives the push rod 5 to rotate, the probe 4 is fixed to the push rod 5, and the lower portion of the probe 4 is provided with a torque detector 2, and the lower portion of the torque detector 2 is provided. The resistance plate 3, the resistance plate 3 is fixed to the probe 4, and the lower portion of the probe 4 is provided with a pairing dried hole 6. The rotating power unit is connected to the push rod 5 through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com