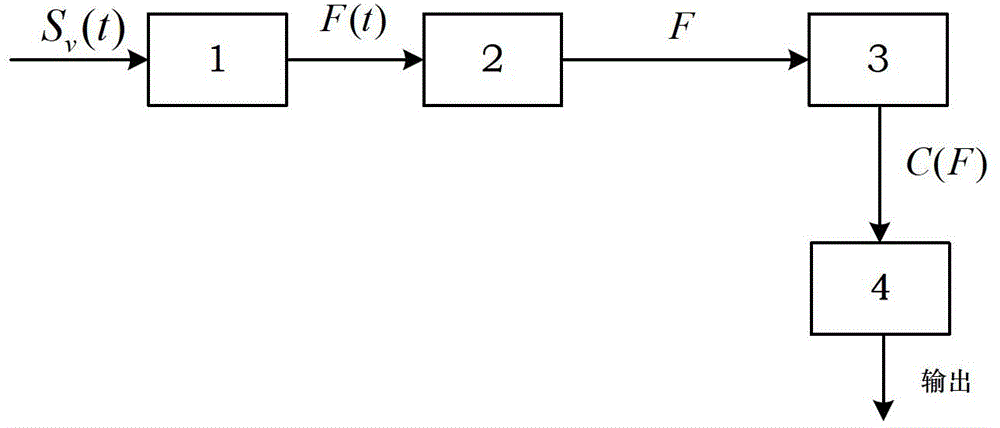

Characterization and quantitative evaluation system for fatigue damage state of in-service 16Mn manganese steel bearing part based on WPT (wavelet packet tactic) and DF (double focusing spectrum) tactic

A technology for fatigue damage and quantitative assessment, which is applied in the processing of detection response signals and the use of sonic emission technology for material analysis. To achieve the effect of ensuring safety and economic benefits, reducing the loss of personnel and property, and accurate and reliable assessment results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Fatigue-loaded acoustic emission testing of load-bearing parts of a 40-ton rail-mounted crane.

[0064] Bearing parts: the effective extension of the cantilever is 5000mm, and the detection length is 3000mm.

[0065] The composition of 16Mn steel used in bearing parts is:

[0066] Table 216Mn steel composition content

[0067] Element C mn Si P S Ca Fe Mass percentage content (%) 0.16 1.42 0.31 0.022 0.033 0.10 margin

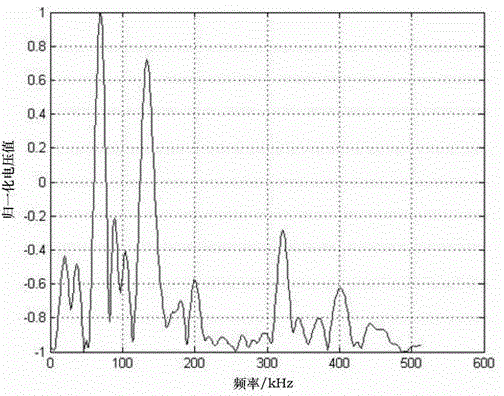

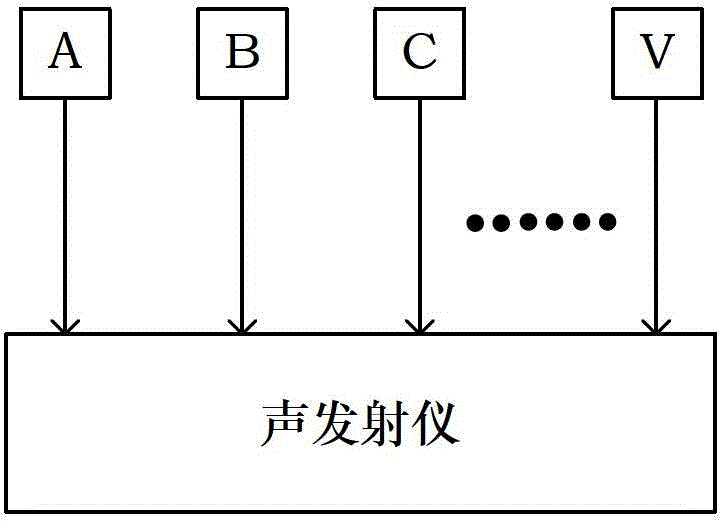

[0068] The detection equipment includes: (A) 4 R15 acoustic emission sensors, the response frequency is 100-400kHz, and the center frequency is 150kHz.

[0069] (B) The acoustic emission instrument is an all-digital 16-channel DiSP acoustic emission system from PAC Corporation of the United States. The threshold value of the acoustic emission instrument detection is 30dB, the acoustic emission peak definition time PDT is 300μs, the acoustic emission impact limit time HDT is 600μs, and the acousti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com