Pressure sensor calibration method and device and electronic equipment

A pressure sensor and calibration method technology, applied in the field of sensor calibration, can solve problems such as low calibration accuracy, inability to ensure accuracy, and difficult calibration process, and achieve the effect of improving calibration accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

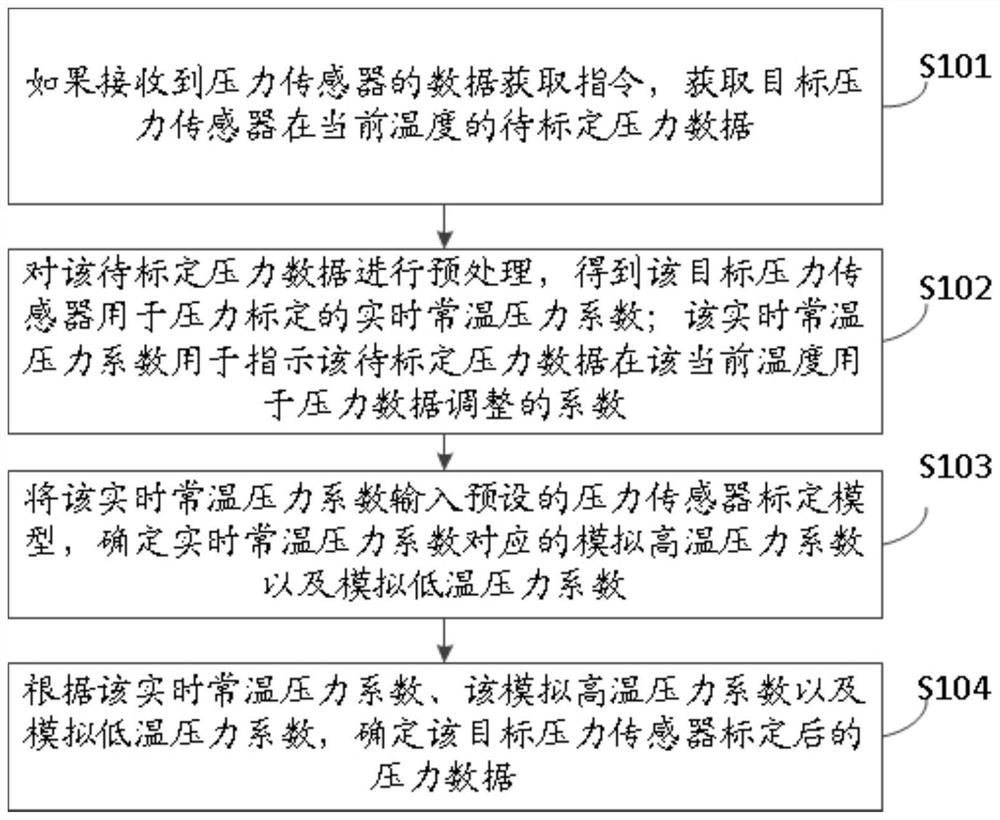

[0029] figure 1 It is a schematic flowchart of a calibration method for a pressure sensor provided in an embodiment of the present invention. figure 1 As seen, the method includes the following steps:

[0030] Step S101: If a data acquisition instruction of a pressure sensor is received, acquire the pressure data to be calibrated of the target pressure sensor at the current temperature.

[0031] In this embodiment, the current temperature is normal temperature, and the temperature range of the normal temperature is: 25°-30°. Then, through the ADC output terminal of the target pressure sensor, the pressure data to be calibrated at the current temperature of the target pressure sensor is obtained.

[0032] Step S102: Preprocessing the pressure data to be calibrated to obtain the real-time normal temperature pressure coefficient of the target pressure sensor for pressure calibration; the real-time normal temperature pressure coefficient is used to indicate that the pressure dat...

Embodiment 2

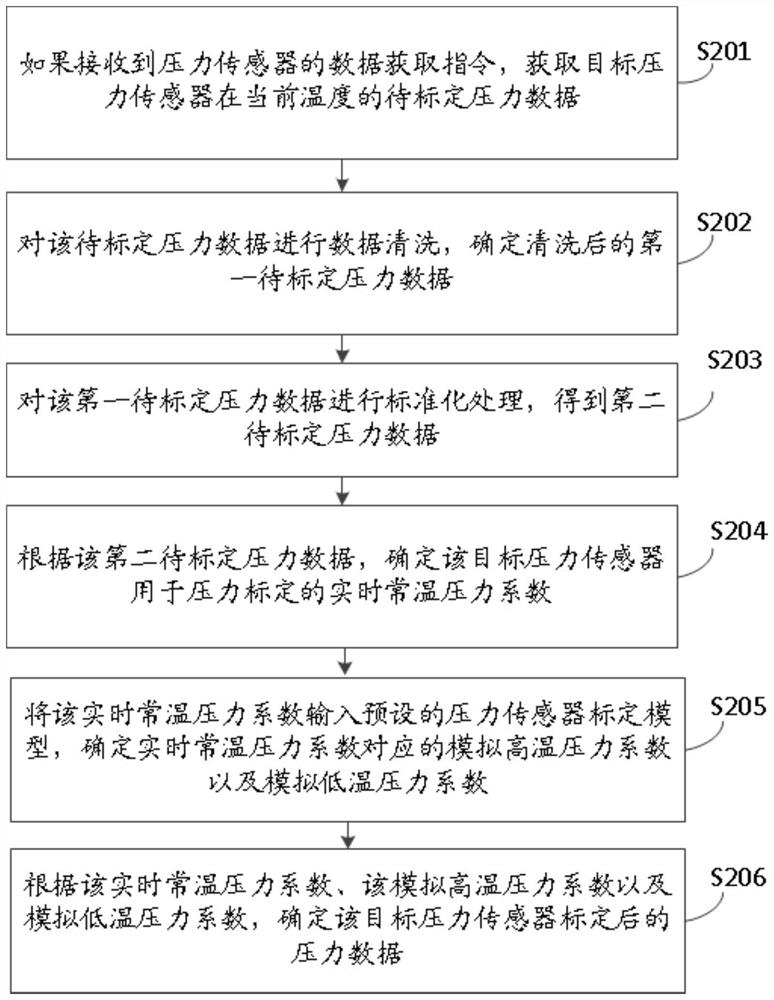

[0039] exist figure 1 On the basis of the schematic flowchart of a calibration method for a pressure sensor shown, this embodiment also provides another calibration method for a pressure sensor. figure 2 It is a schematic flowchart of another pressure sensor calibration method provided by the embodiment of the present invention. The method includes:

[0040] Step S201: If a data acquisition instruction of a pressure sensor is received, acquire the pressure data to be calibrated of the target pressure sensor at the current temperature.

[0041] Step S202: Perform data cleaning on the pressure data to be calibrated, and determine the first pressure data to be calibrated after cleaning.

[0042] In this embodiment, firstly, according to the pressure data, the pressure data to be calibrated beyond the preset analog-to-digital conversion range is determined. Then, delete the pressure data to be calibrated beyond the preset analog-to-digital conversion range, and determine the f...

Embodiment 3

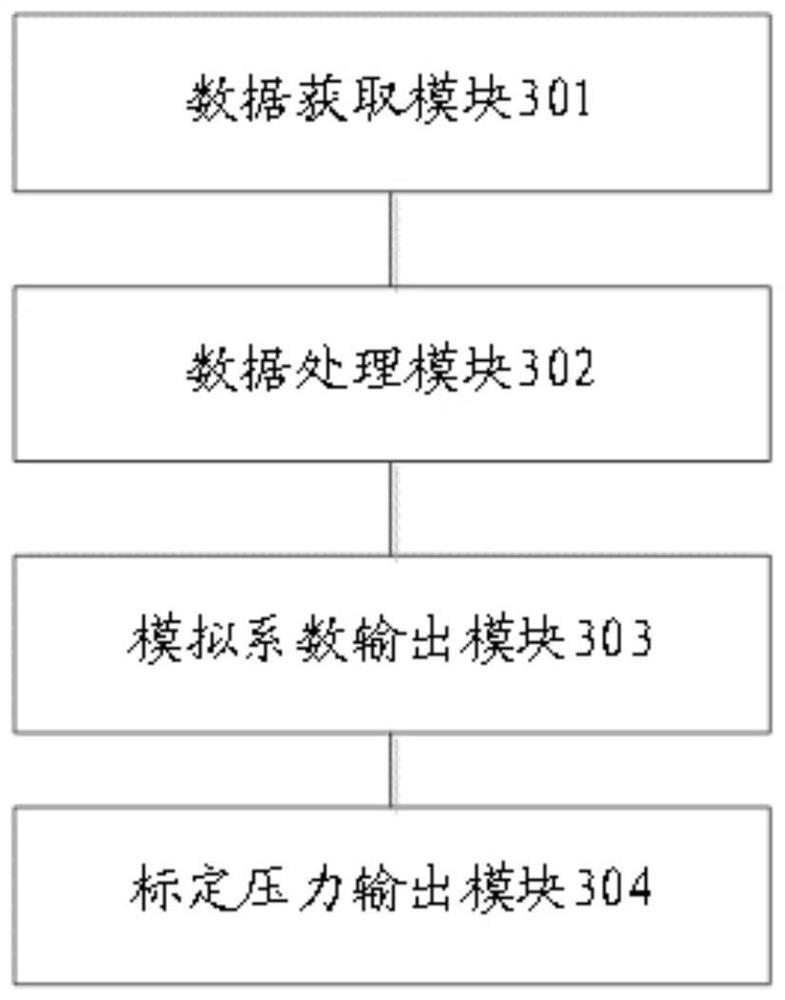

[0082] The embodiment of the invention also provides a calibration device for the pressure sensor. Such as image 3 as shown, image 3 A schematic structural diagram of a pressure sensor calibration device provided in an embodiment of the present invention, the device includes:

[0083] The data acquisition module 301 is configured to acquire the pressure data to be calibrated of the target pressure sensor at the current temperature if a data acquisition instruction from the pressure sensor is received.

[0084] The data processing module 302 is used to preprocess the pressure data to be calibrated to obtain the real-time normal temperature pressure coefficient of the target pressure sensor used for pressure calibration; Coefficient to adjust for pressure data.

[0085] The simulation coefficient output module 303 is configured to input the real-time normal-temperature pressure coefficient into the preset pressure sensor calibration model, and determine the simulated high-t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com