High-dynamic self-shielding pulsed eddy current detection probe and defect detection method

A pulsed eddy current and detection probe technology, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve problems such as hidden safety hazards and cover-ups, and achieve the effects of improving utilization, reducing amplitude, and reducing waste of range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

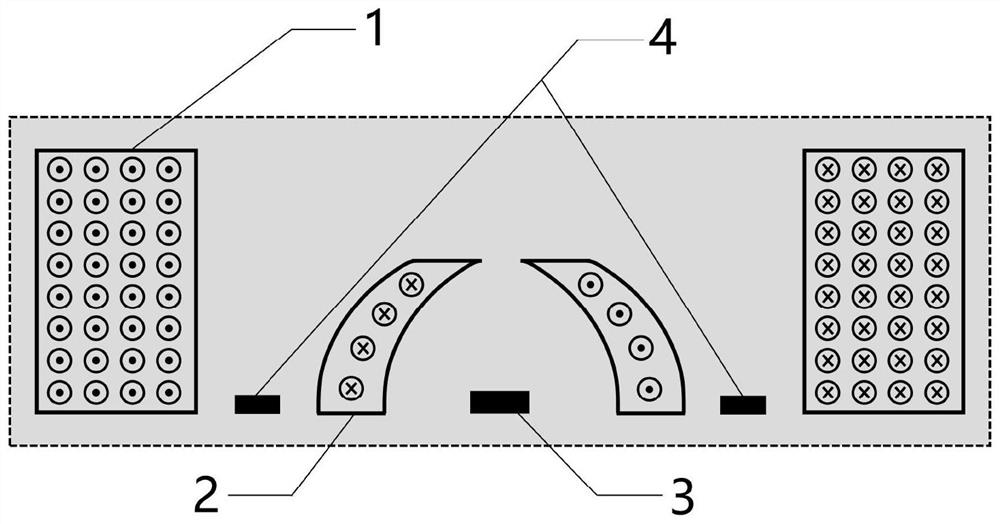

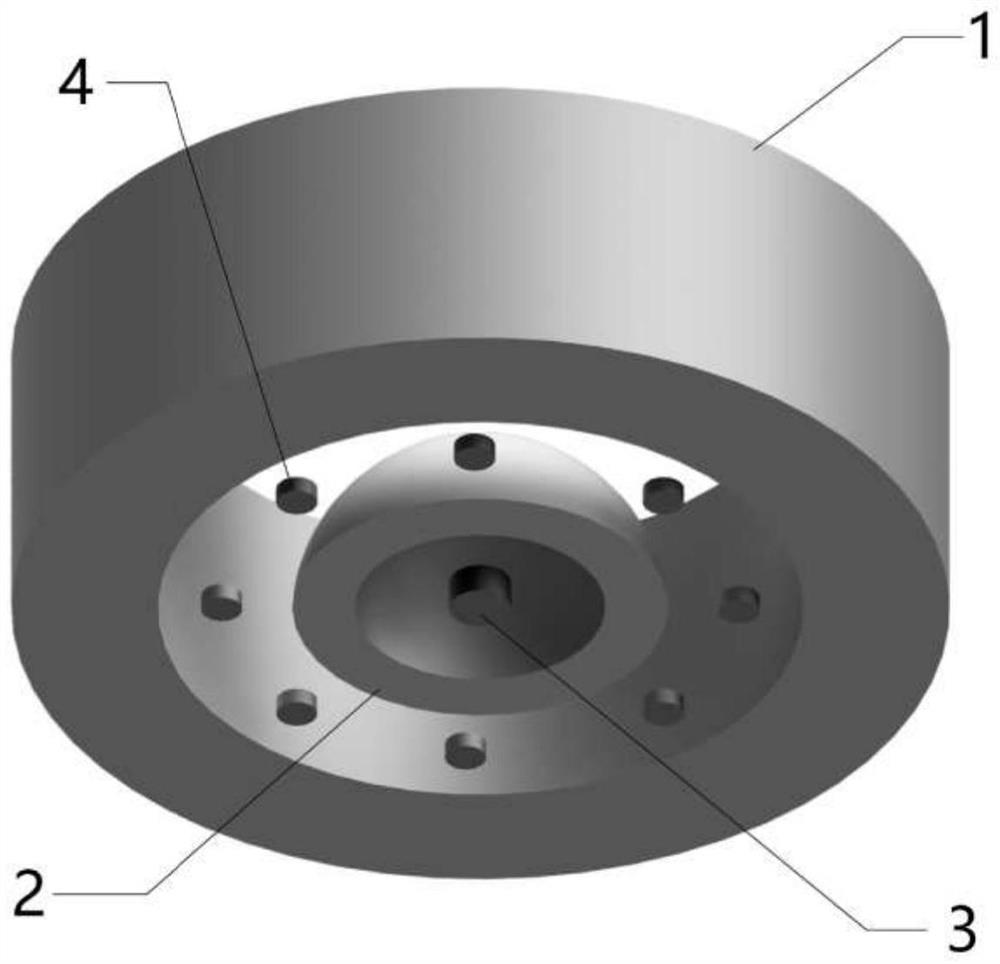

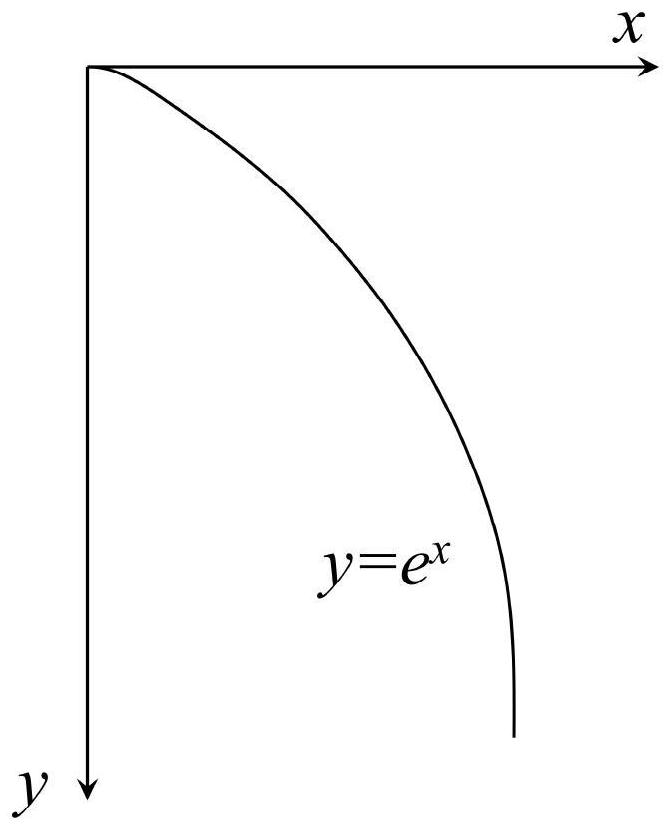

[0030] Such as figure 1 , figure 2 As shown, the high dynamic self-shielding pulsed eddy current detection probe of the present invention includes an external disc excitation coil 1, an internal raspberry type active self-shielding coil, a high-precision magnetic field sensor 3 and a group of annular magnetic field gradient sensor arrays 4; The 1-axis section of the disc excitation coil is rectangular, and the inner raspberry type has the same length as the upper and lower bottom sides of the 2-axis section of the shielding coil. The inner and outer sides are exponential curves, and the side curves and expressions are as follows image 3 As shown; the external disc excitation coil 1 and the internal raspberry type active shielding coil 2 are coaxially placed, and the connection mode of the external disc excitation coil 1 and the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com