Electric car motor controller

A technology for motor controllers and electric vehicles, applied in the direction of AC motor control, control systems, electrical components, etc., can solve the problems of low motor controller integration, large controller dimensions, and no consideration of safety protection, etc., to achieve Reliability, compact structure, good heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

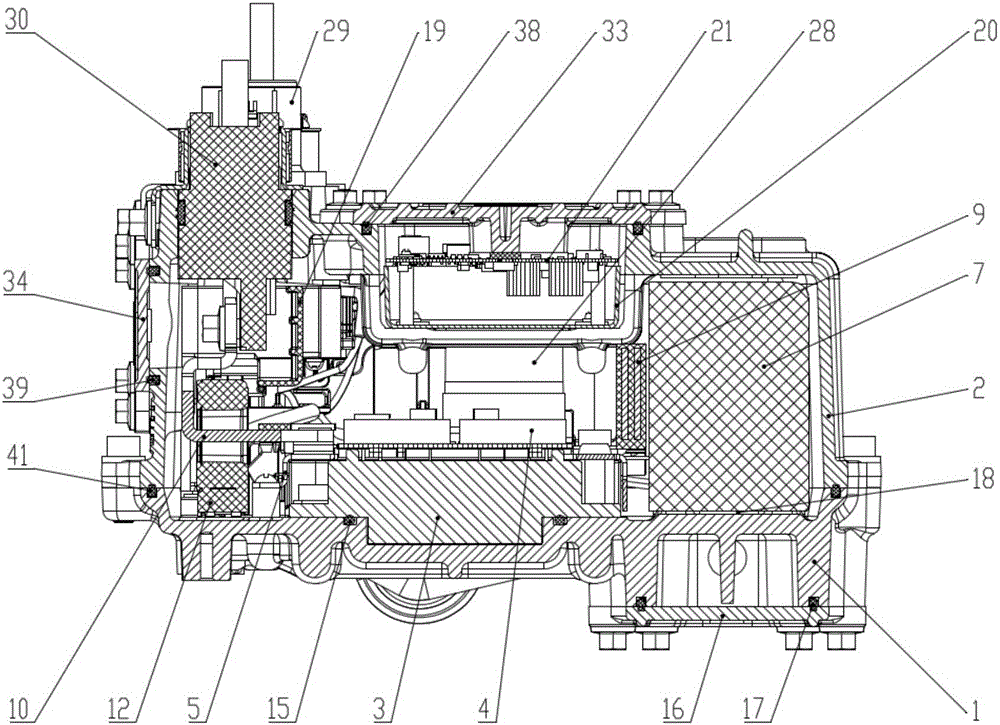

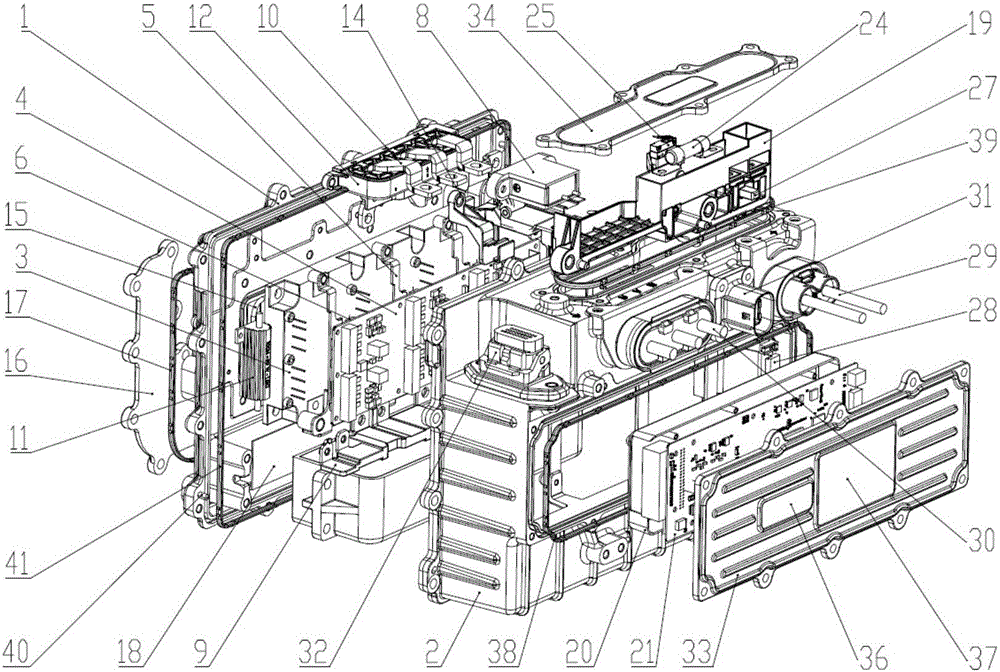

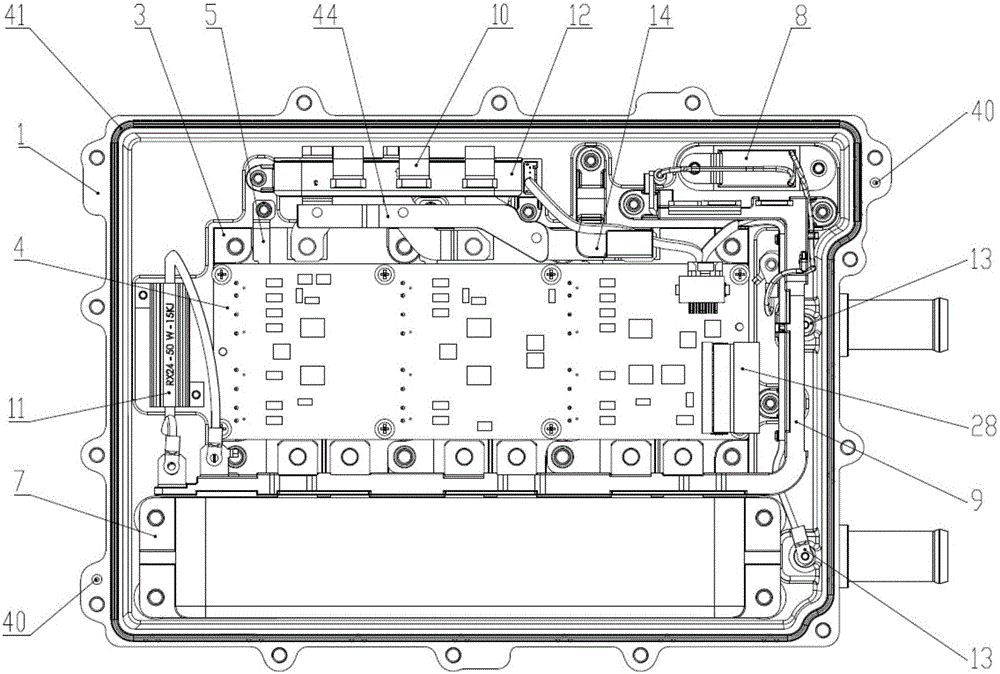

[0031] see Figure 1-Figure 5 , this embodiment discloses an electric vehicle motor controller, including a main box 1 and an upper box 2, and each functional component of the electric vehicle motor controller is installed in the described The inside or outside of the main box 1 and the upper box 2, and then realize the compact integration of the functional components of the motor controller through the main box 1 and the upper box 2, and further realize various functions. The electrical connection of the components is simpler and more efficient, improving the reliability and power density of the motor controller.

[0032] Specifically, the main box 1 is preferably arranged in a rectangular structure so as to fit the layout of the vehicle boundary. In order to facilitate the connection with the upper box 2, it is preferred in this embodiment that the main box 1 The edge on one side is protruding, and its interior is used to install various functional components of the motor c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com