Board card quality detection method, device and equipment and readable storage medium

A quality detection method and detection device technology, which is applied in image analysis, image enhancement, instruments, etc., can solve problems such as large influence, unfavorable quality detection results, and different detection results, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

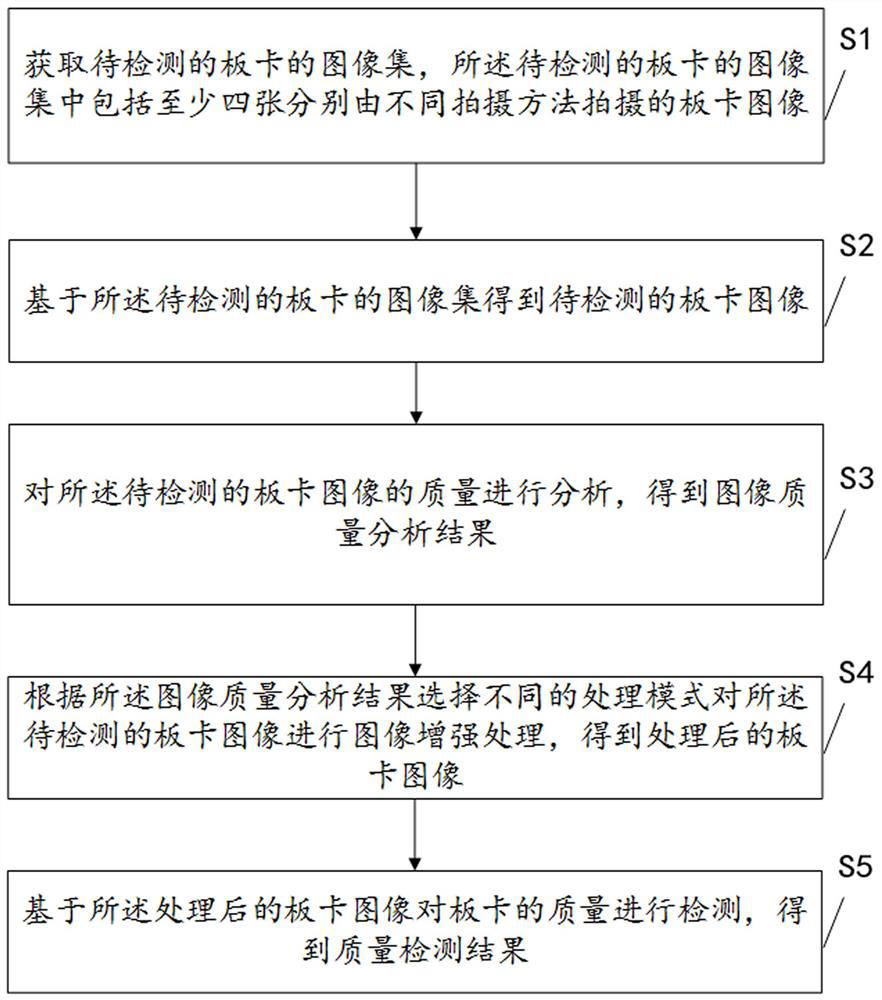

[0075] Such as figure 1 As shown, this embodiment provides a board quality detection method, the method includes step S1, step S2, step S3, step S4 and step S5.

[0076] Step S1, acquiring an image set of the board to be detected, the image set of the board to be detected includes at least four board images respectively taken by different shooting methods;

[0077] Step S2, obtaining the image of the board to be detected based on the image set of the board to be detected;

[0078] Step S3, analyzing the quality of the image of the board card to be detected, and obtaining an image quality analysis result;

[0079] Step S4, selecting a different processing mode according to the image quality analysis result to perform image enhancement processing on the board image to be detected to obtain a processed board image;

[0080] Step S5 , inspecting the quality of the board based on the processed image of the board, and obtaining a quality inspection result.

[0081] In this embodi...

Embodiment 2

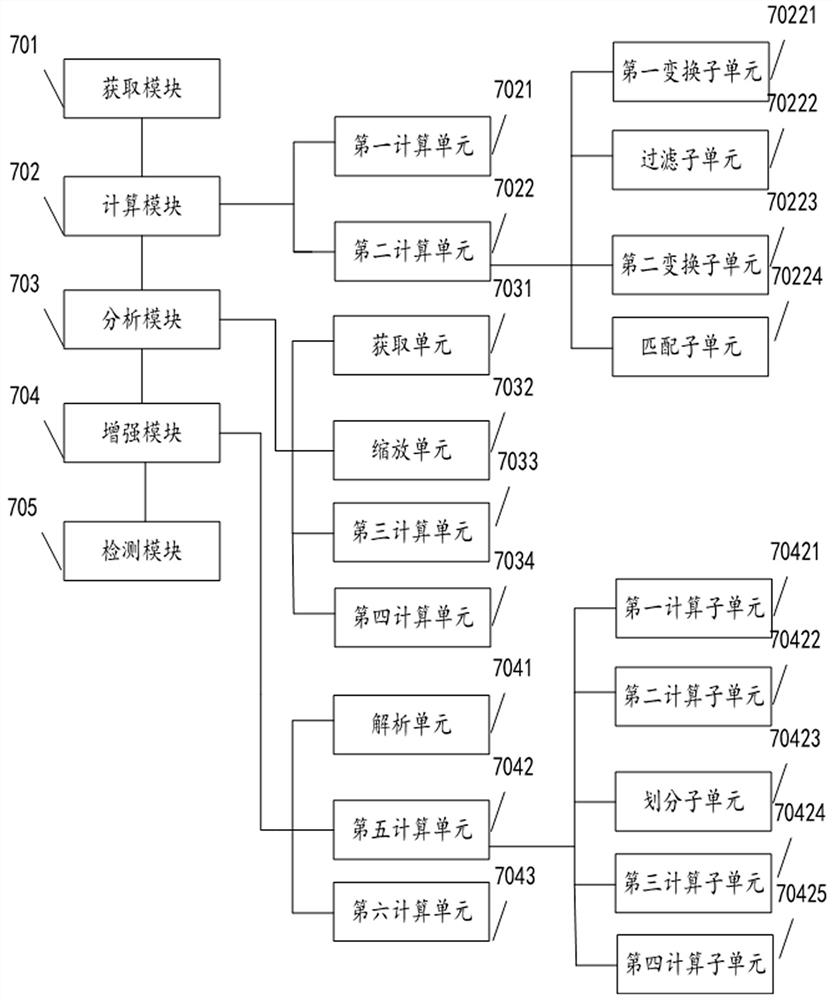

[0114] Such as figure 2 As shown, this embodiment provides a board quality detection device, which includes an acquisition module 701 , a calculation module 702 , an analysis module 703 , an enhancement module 704 and a detection module 705 .

[0115] The acquiring module 701 is configured to acquire an image set of the board to be detected, the image set of the board to be detected includes at least four board images respectively taken by different shooting methods;

[0116] Calculation module 702, for obtaining the image of the board card to be detected based on the image set of the board card to be detected;

[0117] An analysis module 703, configured to analyze the quality of the board image to be detected, and obtain an image quality analysis result;

[0118] An enhancement module 704, configured to select a different processing mode according to the image quality analysis result to perform image enhancement processing on the board image to be detected, to obtain a proc...

Embodiment 3

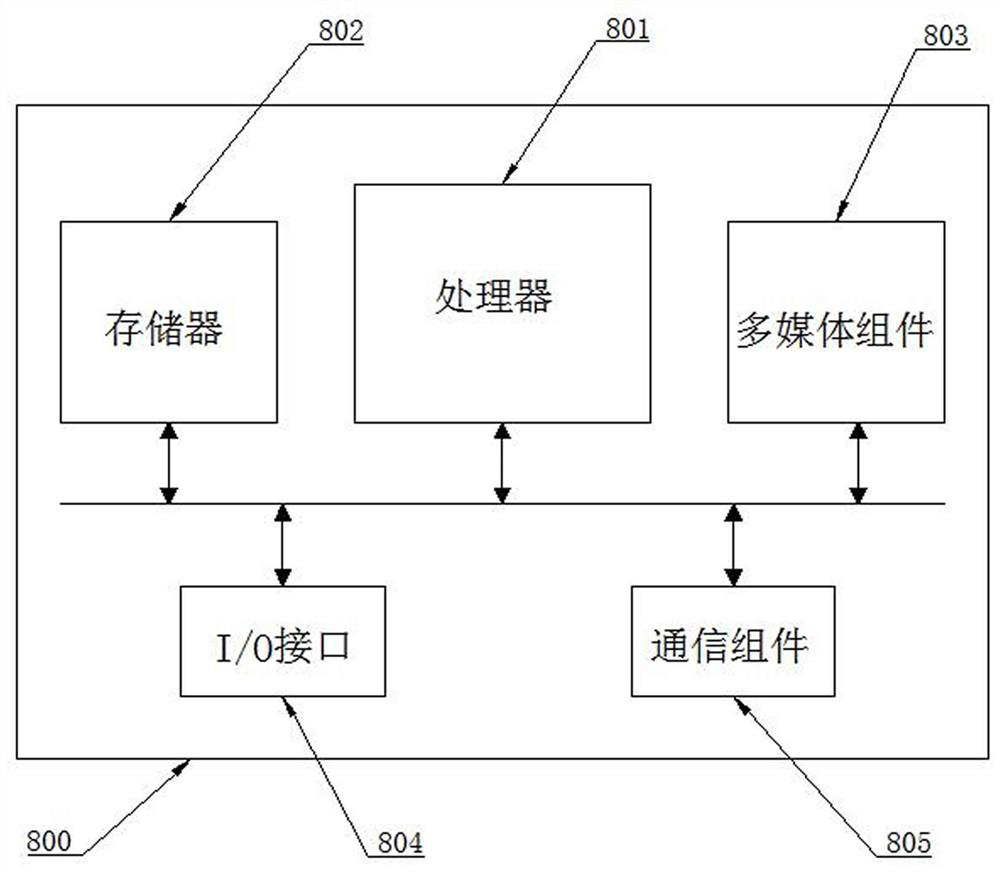

[0146] Corresponding to the above method embodiments, the embodiment of the present disclosure further provides board quality inspection equipment, and the board quality inspection equipment described below and the board quality inspection method described above can be referred to in correspondence with each other.

[0147] image 3 It is a block diagram of a board quality inspection device 800 shown according to an exemplary embodiment. Such as image 3 As shown, the board quality inspection device 800 may include: a processor 801 and a memory 802 . The board quality inspection device 800 may also include one or more of a multimedia component 803 , an input / output (I / O) interface 804 , and a communication component 805 .

[0148] Wherein, the processor 801 is used to control the overall operation of the board quality inspection device 800, so as to complete all or part of the steps in the above board quality inspection method. The memory 802 is used to store various types ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com