Large-current electric tool switch

A power tool and high-current technology, which is applied to electric switches, flip switches/rocker switch components, circuits, etc., can solve the problem of temperature rise of switches, shortened service life, difficult to solve the problem of fast on-off of switches and dynamic and static contacts Anti-bounce, anti-arc and other issues to achieve the effect of reducing temperature rise and reducing local heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The embodiments of the present invention will be further described in detail according to the above-mentioned drawings.

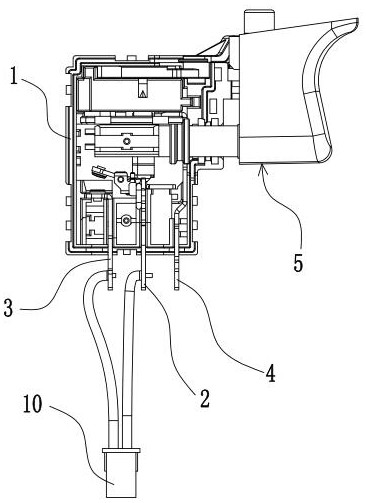

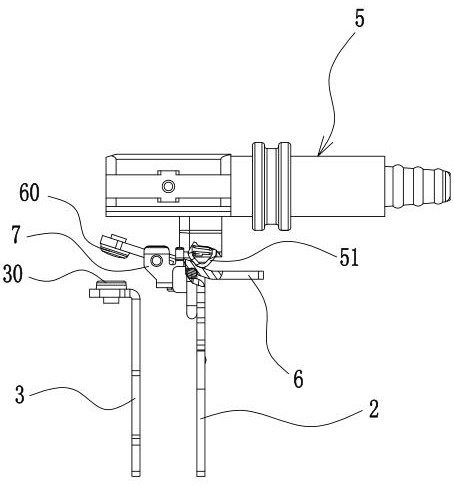

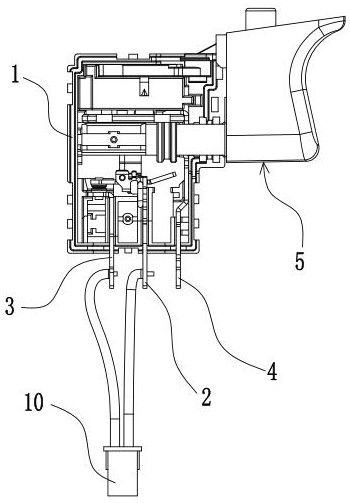

[0045] Such as Figure 1~Figure 28 As shown, 1. Shell, 10. Connector assembly, 11. Bottom shell, 111. Buckle groove, 12. Shell cover, 13. Spring, 14. Conductive rod, 2. Bracket terminal, 21. Positioning tongue, 211 .Positioning column, 212. Positioning gap, 22. Connection gap, 23. Connection hole, 24. Connection pin, 25. Mounting groove, 26. Anti-loose convex shell, 3. Static contact piece terminal, 30. Static contact, 4. Positive pole terminal, 5. Trigger assembly, 51. Warhead, 52. Push rod, 521. End hole, 522. Side hole, 53. Dustproof ring, 54. Trigger block, 55. Locating pin, 56. Push rod spring , 57. Bullet spring, 6. Conductive bridge, 60. Moving contact, 61. Arc groove, 62. Quick on-off protrusion, 621. First shift point, 622. Second shift point, 63. Limiting slot, 64. Chamfer slope, 7. Elastic seat, 71. Bottom plate, 711. Positioning hole, 7...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com