Air entraining window of RAT generator

A generator and window technology, applied to the cooling system of the power plant, etc., can solve the problems of high processing cost, complicated manufacturing process of the bleed window, and great influence on the weight of the overall mechanism, so as to reduce maintenance cost, reduce manufacturing difficulty, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

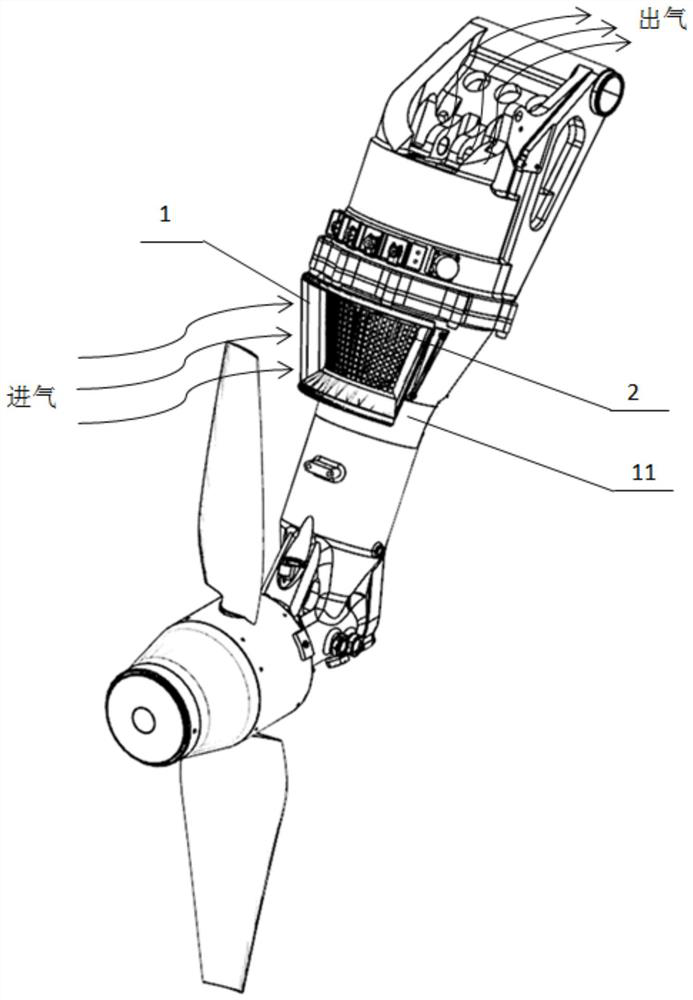

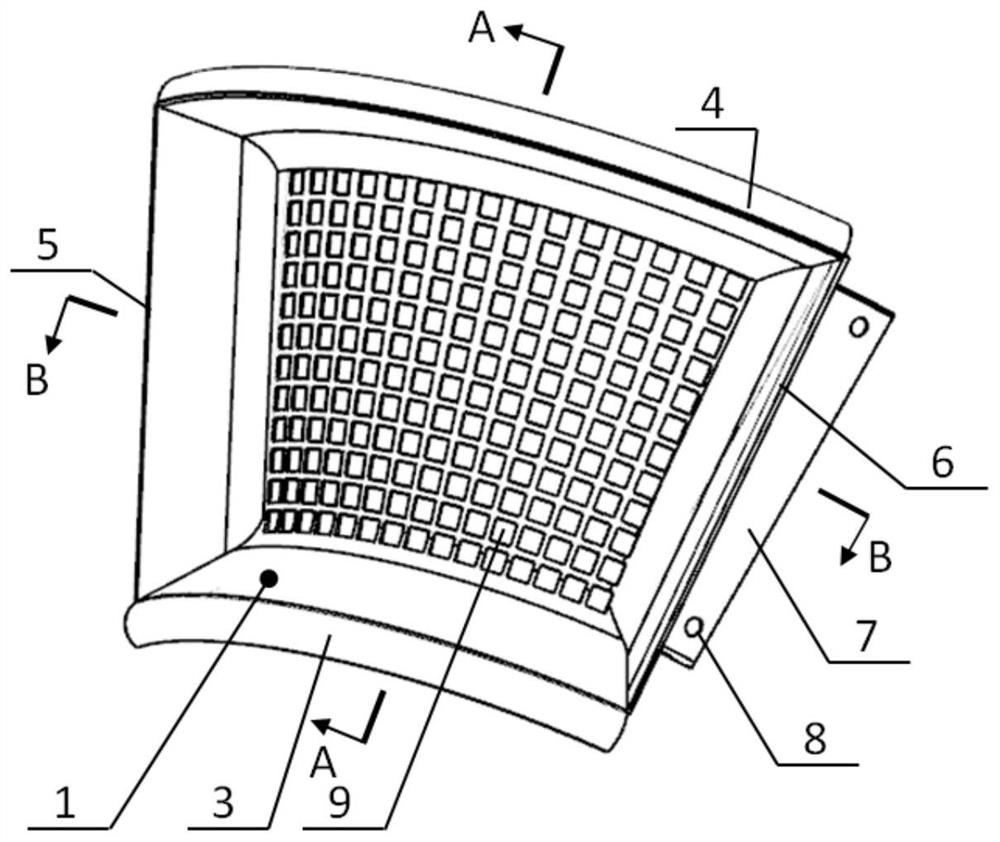

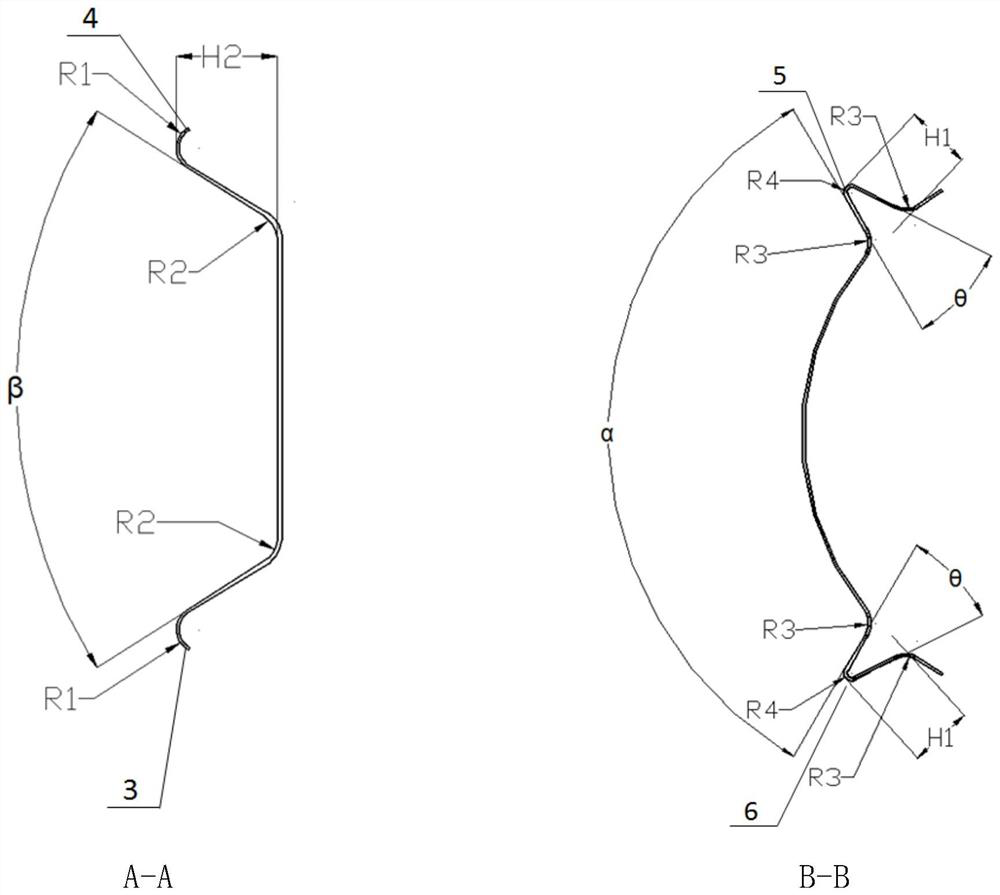

[0031] Example 1. A kind of RAT generator bleed air window, constitutes as Figure 1-5 As shown, it includes a support arm hole 2 arranged on the generator support arm 11, and the support arm hole 2 is covered with a trumpet-shaped drainage cover 1; the drainage cover 1 includes U-shaped lips I3 and U-shaped lips II4 arranged oppositely, U-shaped lip Ⅲ5, U-shaped lip Ⅳ6 and hole net 9 arranged oppositely; U-shaped lips Ⅰ~Ⅳ constitute the quadrilateral large-end air inlet of the drainage hood 1, and holes are provided at the small-end air outlet of the drainage hood 1 Net 9, hole net 9 and the support arm 11 taper surface of support arm hole 2 places are bonded. The air is drained through the shroud 1 , passes through the support arm hole 2 and then flows through the RAT generator. After the generator is cooled, it is exhausted through the upper end of the generator.

[0032] The drainage cover 1 is a thin-walled sheet metal part with a thickness of 0.6 mm to 1 mm. The drain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com