Impeller air-entrainer air-float device

A technology of air flotation and impeller, which is applied in the direction of flotation water/sewage treatment, etc. It can solve the problems of small air entrainment capacity, insufficient air entrainment capacity, and poor gas-liquid mixing effect, so as to reduce emissions, prevent pollution of the working environment, The effect of easy scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structure and operation mode of the present invention will be further described below in conjunction with the accompanying drawings.

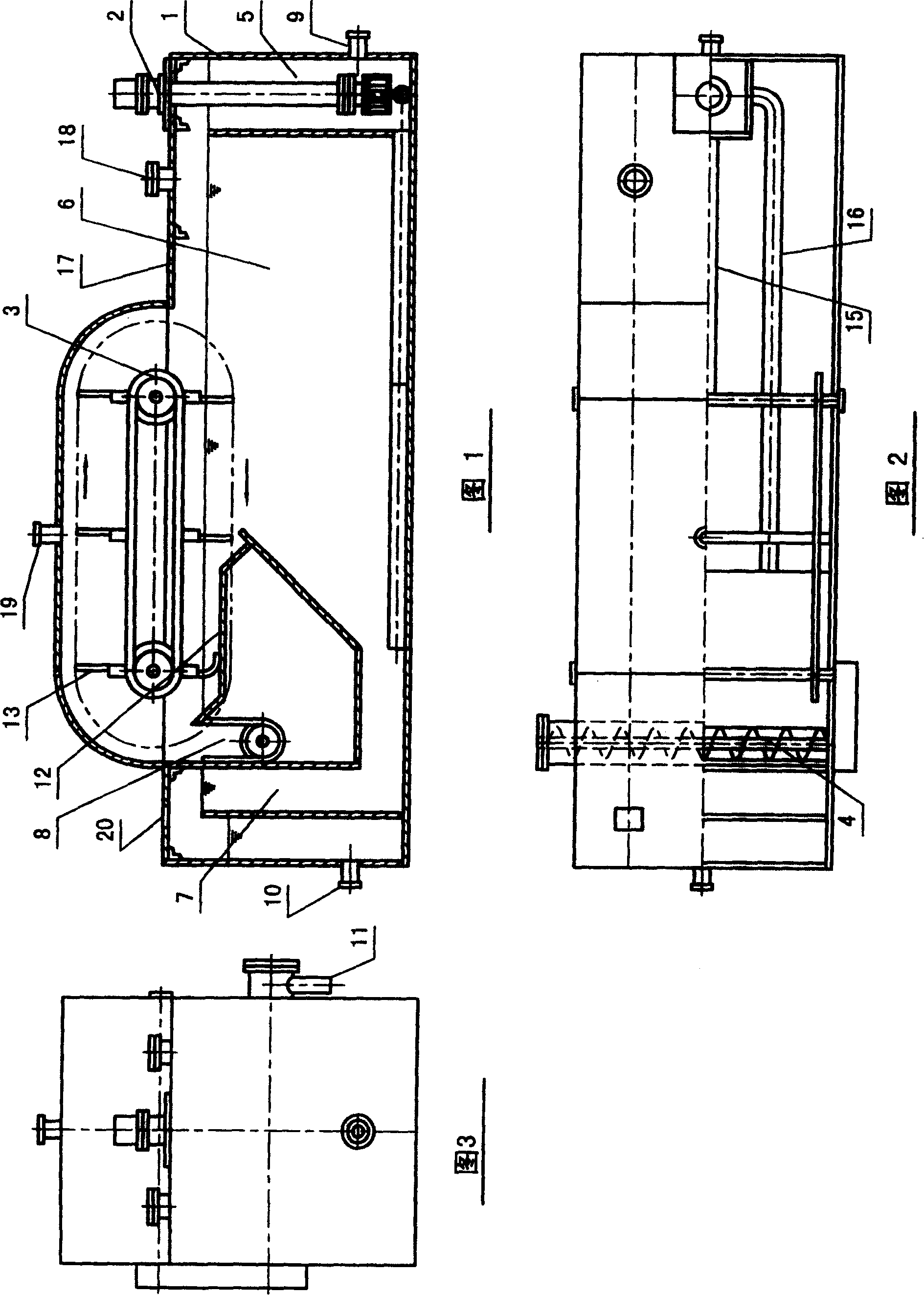

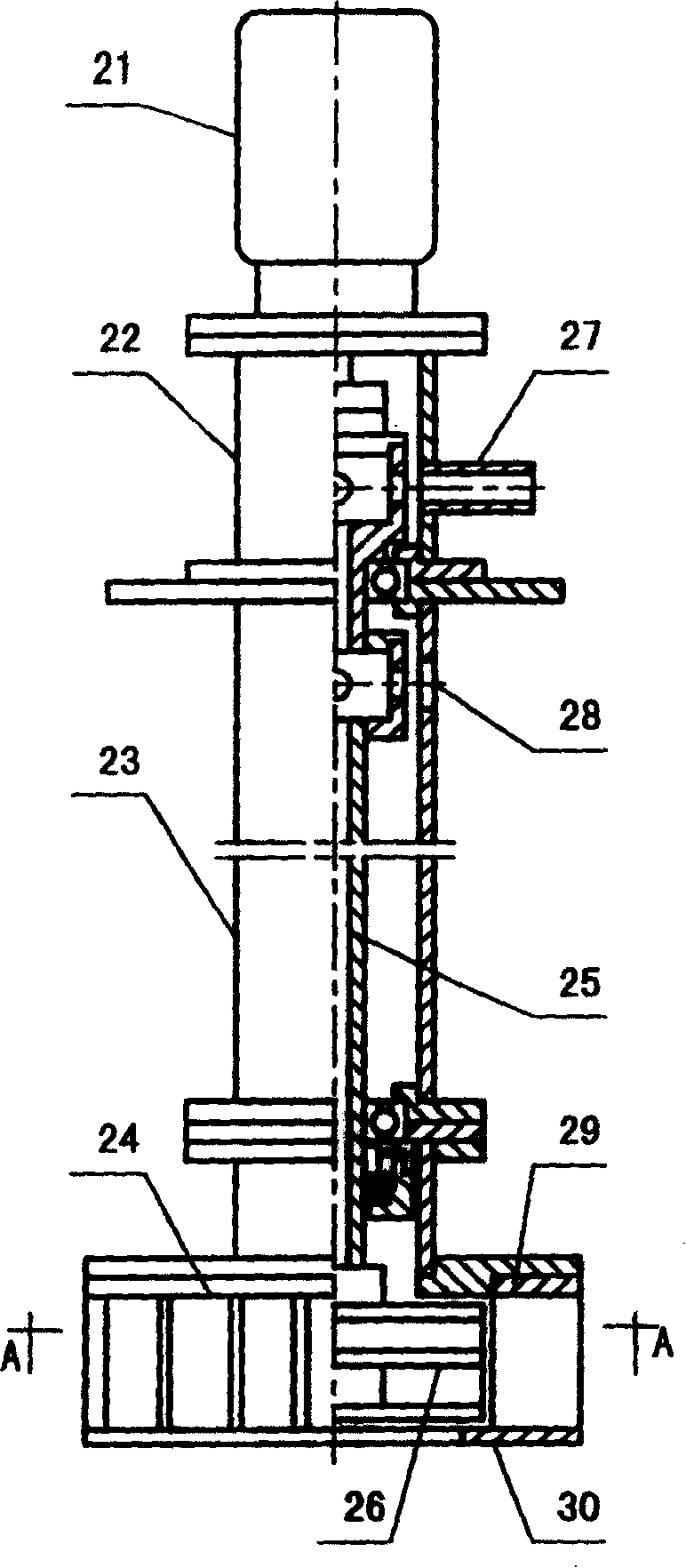

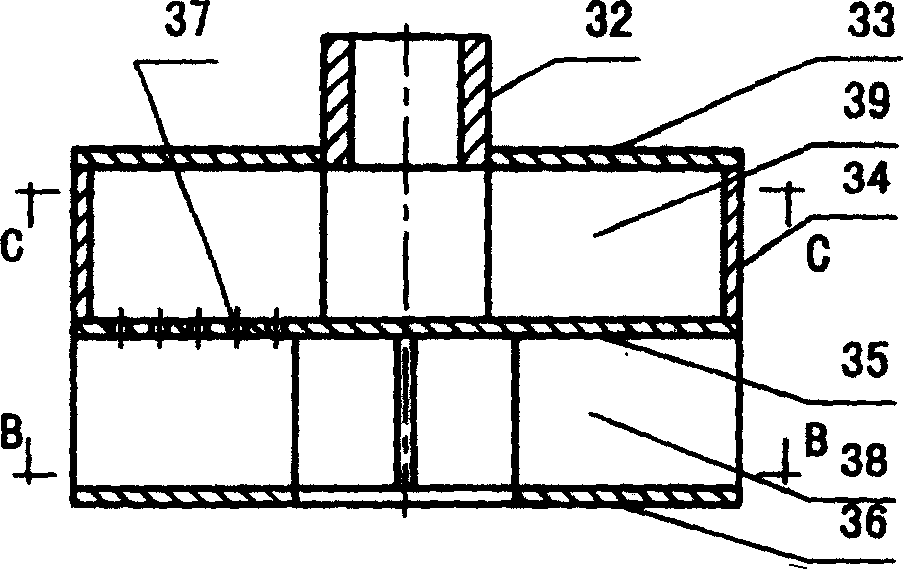

[0035] As shown in Figure 1, Figure 2 and Figure 3, the impeller-induced air flotation device includes a tank body 1, an aerator 2, a chain type slag scraper 3, a slag guide plate 12 and a screw conveyor 4. The tank body 1 is divided into an aeration zone 5, a separation zone 6, and an overflow water outlet zone 7 by corresponding partitions; The tank body 1 is equipped with a folded plate-shaped slag guide plate 12, whose front and rear parts are inclined plates, and the middle part is a horizontal straight plate; The return pipe 16; the top of the pool body is provided with a sealing cover plate 17, and the top of the cover plate is provided with a bubble observation window 18, an exhaust pipe 19 and a water outlet observation port 20. The water to be treated enters the aeration zone 5 from the water inlet 9, and enters the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com