Vehicle sign double-sided detection equipment and detection system

A technology for testing equipment and signs, applied in measuring devices, material analysis through optical means, instruments, etc., can solve problems such as low efficiency and manual turning over, and achieve the effect of reducing wear and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

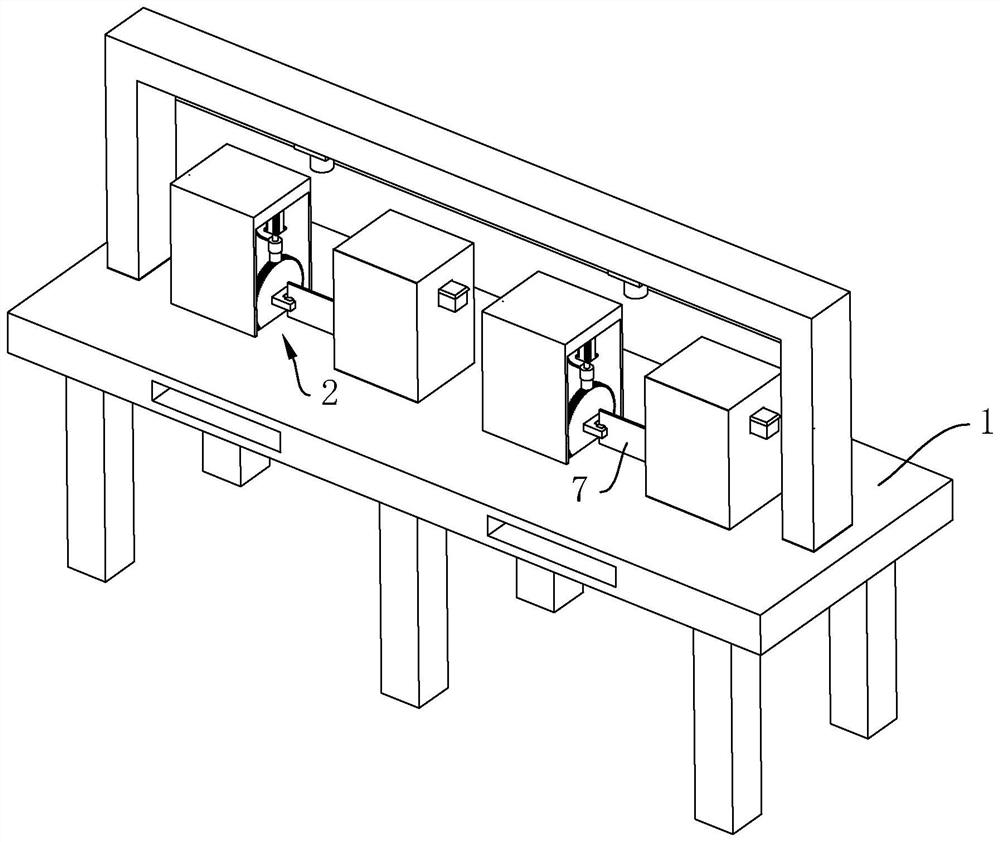

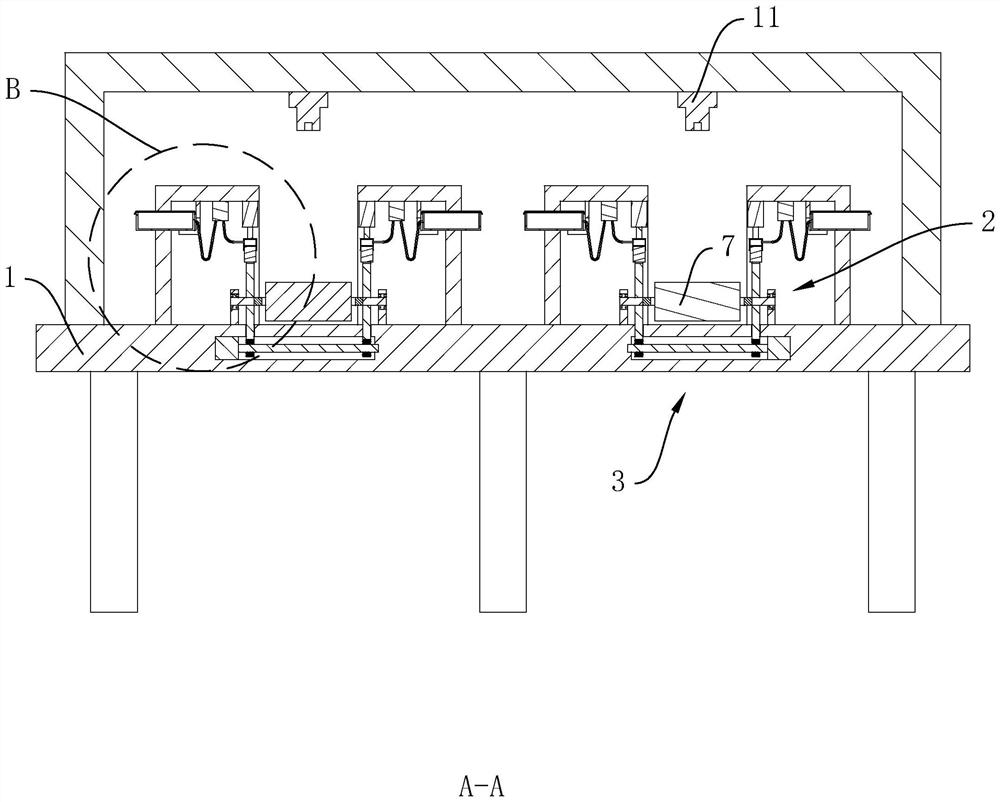

[0049] Embodiment The implementation principle of a vehicle label double-sided detection device is as follows: the operator inserts the two ends of the vehicle label 7 into the clamping assembly 2 respectively; Move in the slot 212, and finally the clamping arc blocks 22 on both sides drive the sealing soft bag 23 against the car label 7; at this time, the rotating motor 31 is started, and the rotating motor 31 drives the first gear 32 to rotate, and the first gear 32 drives The second gear 33 rotates, and the second gear 33 drives two clamping blocks 21 to rotate synchronously, and the two clamping blocks 21 drive the car sign 7 to rotate, and the car sign 7 will face the different faces of the CCD camera 11, thereby realizing the vehicle Double-sided detection of the label 7; through the rotation of the rotating drive assembly 3 to the driving and rotation of the clamping assembly 2, the clamping assembly 2 drives the clamped vehicle label 7 to rotate, realizing the automatic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com