A bearing noise automatic detection machine

A detection machine and bearing technology, applied in mechanical bearing testing, measuring devices, measuring ultrasonic/sonic/infrasonic waves, etc., can solve problems such as low detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

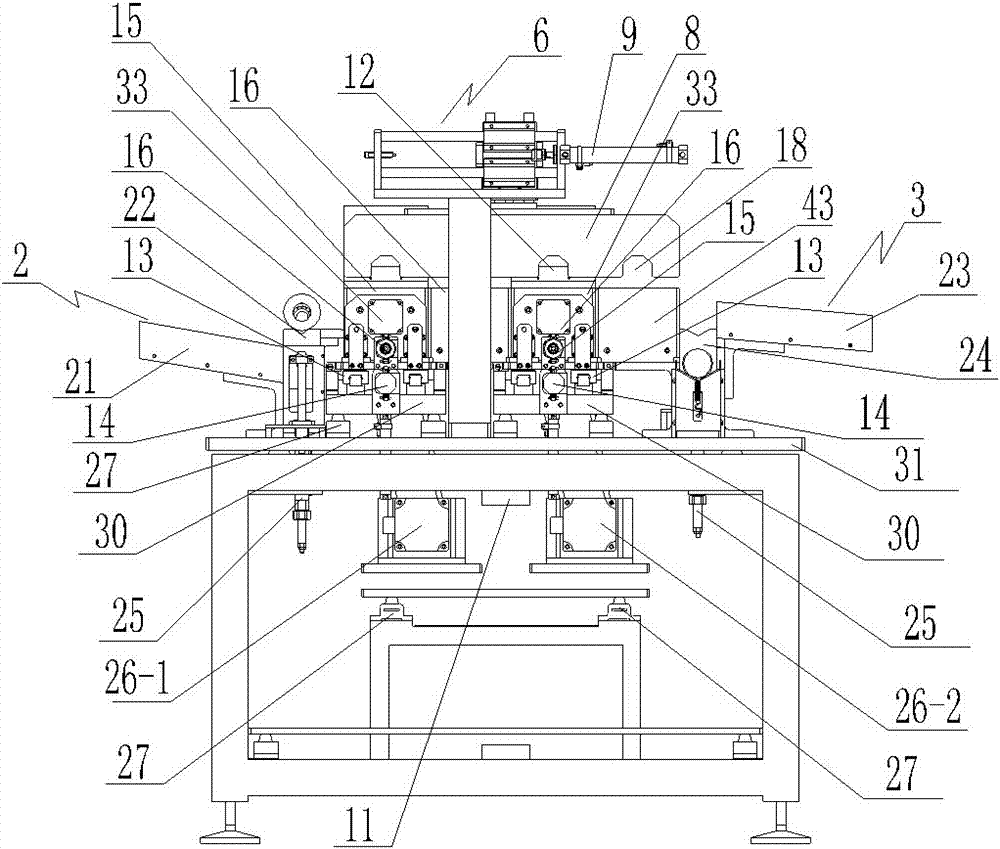

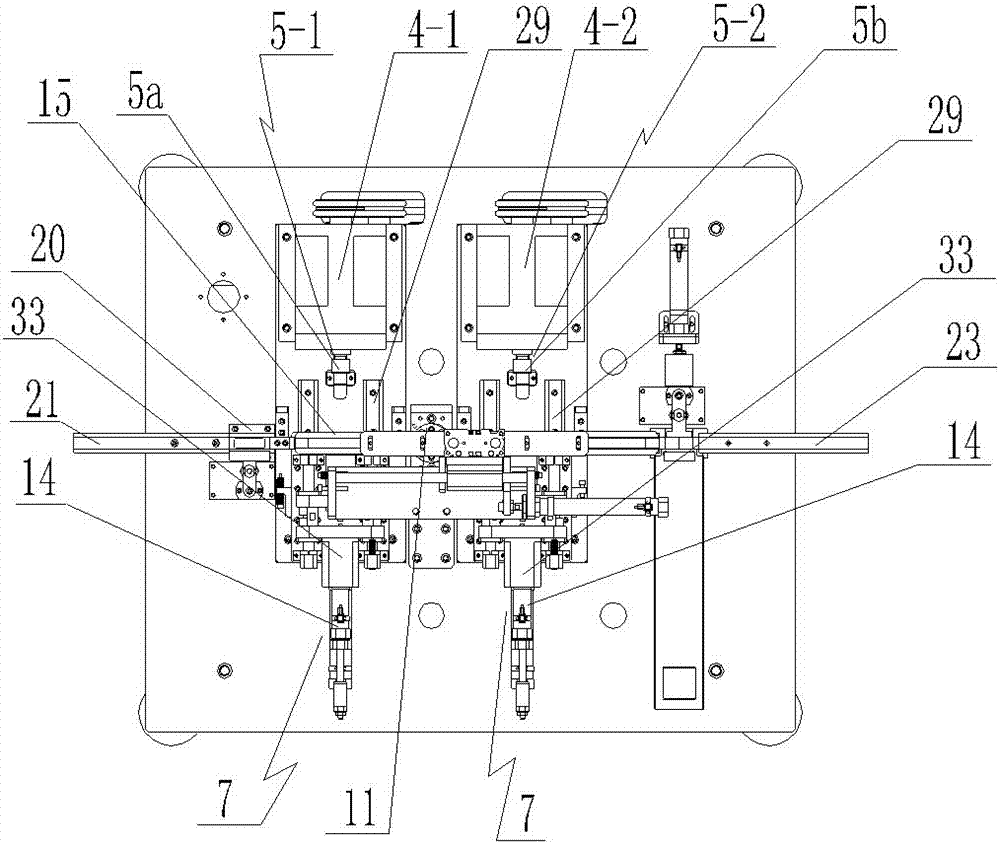

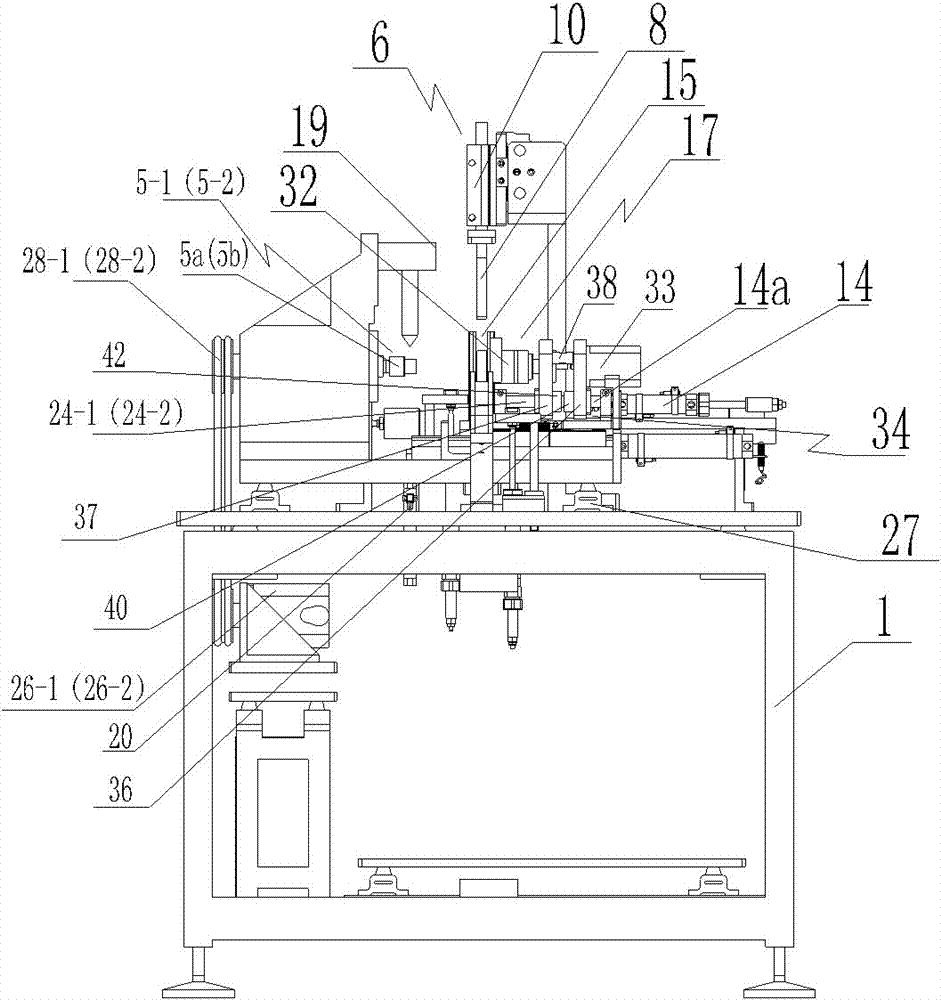

[0021] An automatic detection machine for bearing noise, which includes a frame 1, a feeding device 2 and a discharging device 3 are respectively arranged at both ends of the frame 1, and two rotating devices 4-1 and 4-2 are arranged on the frame 1, The rotating devices 4-1, 4-2 are respectively provided with bearing rotating heads 5-1, 5-2, and the corresponding rotating devices 4-1, 4-2 on the frame 1 are provided with a transverse bearing material transfer mechanism 6 and a longitudinal bearing loading mechanism. Device 7, the transverse bearing material transfer mechanism 6 comprises a fork material plate 8, the fork material plate 8 is respectively connected to the horizontal cylinder 9 and the longitudinal cylinder 10, the fork material plate 8 can move horizontally and vertically through the guide, and the fork material plate 8 is provided with three The fork trough 12 corresponding to the bearing, the longitudinal bearing loading device 7 respectively includes a carriag...

Embodiment 1

[0022] In embodiment one, embodiment two:

[0023] See figure 1 , figure 2 , image 3 , Figure 4 middle:

[0024] On the frame, the corresponding bearing rotating heads 5-1 and 5-2 are provided with an oiling cylinder 20, and the action of the oiling cylinder realizes the oiling of the bearing rotating head, ensuring that the bearing rotating heads 5-1 and 5-2 are inserted into the inner hole of the bearing The lubrication can effectively avoid the damage of the bearing.

[0025] The feeding device 2 includes a feeding channel 21, and one end of the feeding channel 21 is provided with a feeding end support plate 22, and the discharging device 3 includes a discharging channel 23, and one end of the discharging channel 23 is provided with a discharging end holder. The feeding plate 24, the feeding end supporting plate 22 and the discharging end supporting plate 24 are respectively connected to the jacking cylinder 25, through the action of the jacking cylinder 25, the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com