Visual inspection-based quality control system for display backboard

A visual detection and control system technology, applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of poor consistency of detection, cost increase and low efficiency, and achieve a simple and reliable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

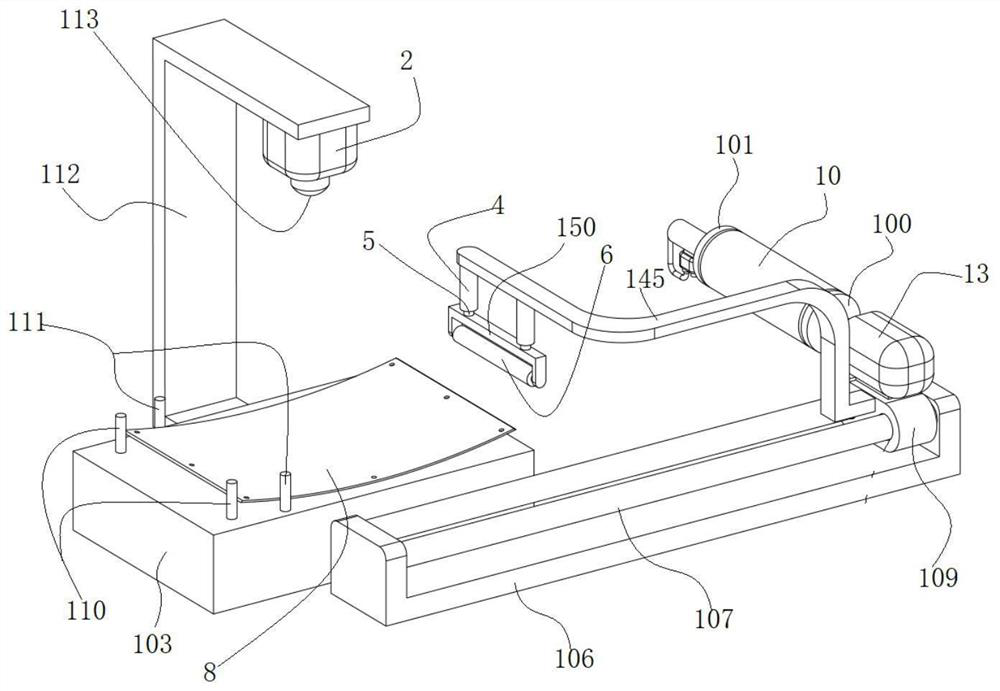

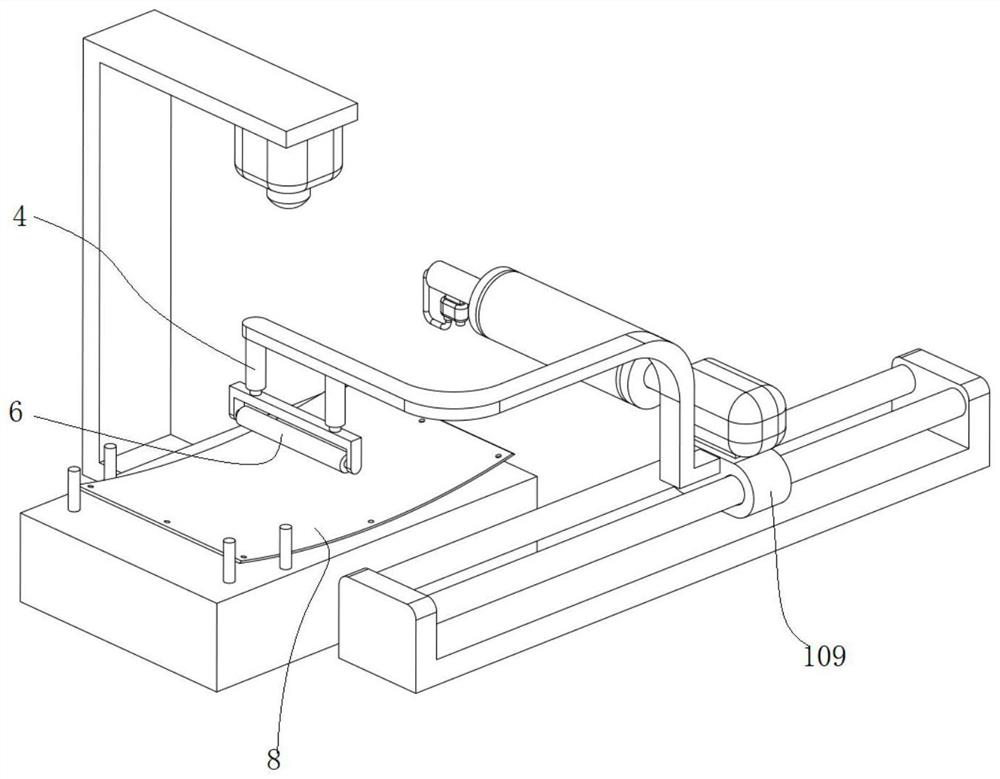

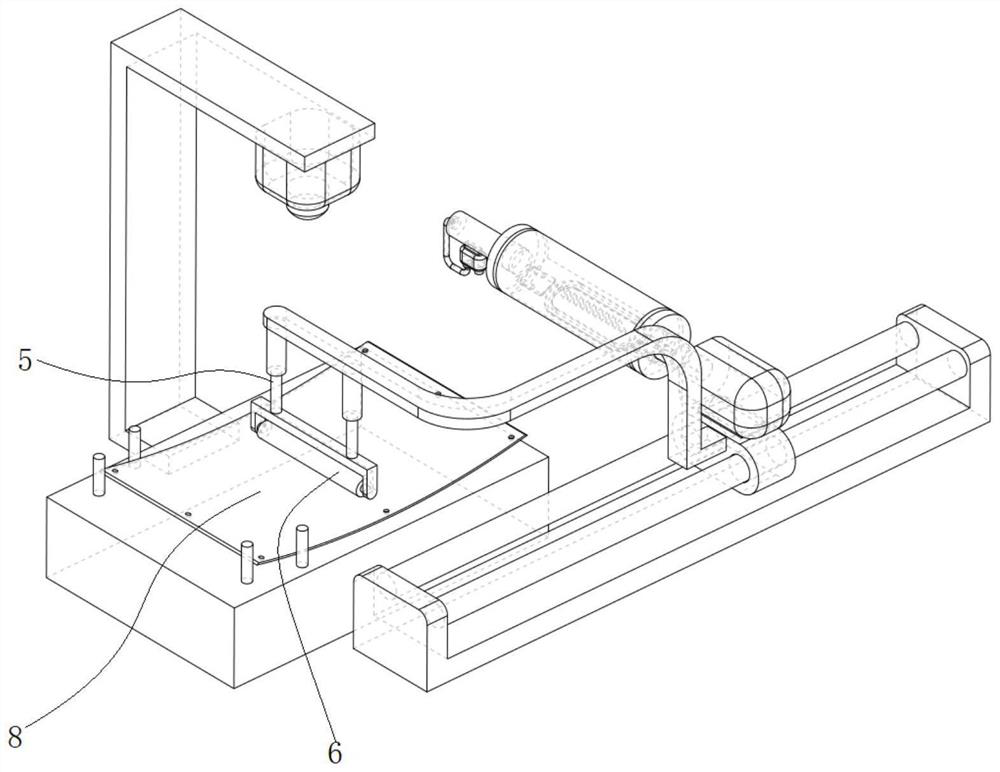

[0033] The present invention will be further described below in conjunction with the accompanying drawings.

[0034] as attached Figures 1 to 14 The shown quality control system of the display backplane based on visual inspection includes the detected curved display backplane 8, and the two curved sides of the curved display backplane 8 are respectively recorded as the first curved side 8.1 and the second curved side 8.1. Two curved sides 8.2, the two straight sides of the curved display back panel 8 are respectively recorded as the first straight side 8.3 and the second straight side 8.4, and the midpoint of the first curved side 8.1 and the second curved side The line connecting the midpoints of 8.2 is recorded as the symmetry line 29;

[0035] It also includes fixed platform 103, visual camera 2 and flip mechanism directly above fixed platform 103. The flip mechanism can turn the curved display backboard 8 with the concave surface upwards into a convex surface; The camer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com