Horizontal machining center zero point alignment tool and alignment method

A machining center, horizontal technology, applied in the direction of metal processing machinery parts, metal processing equipment, manufacturing tools, etc., to achieve the effect of low personal skill requirements, save alignment time, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

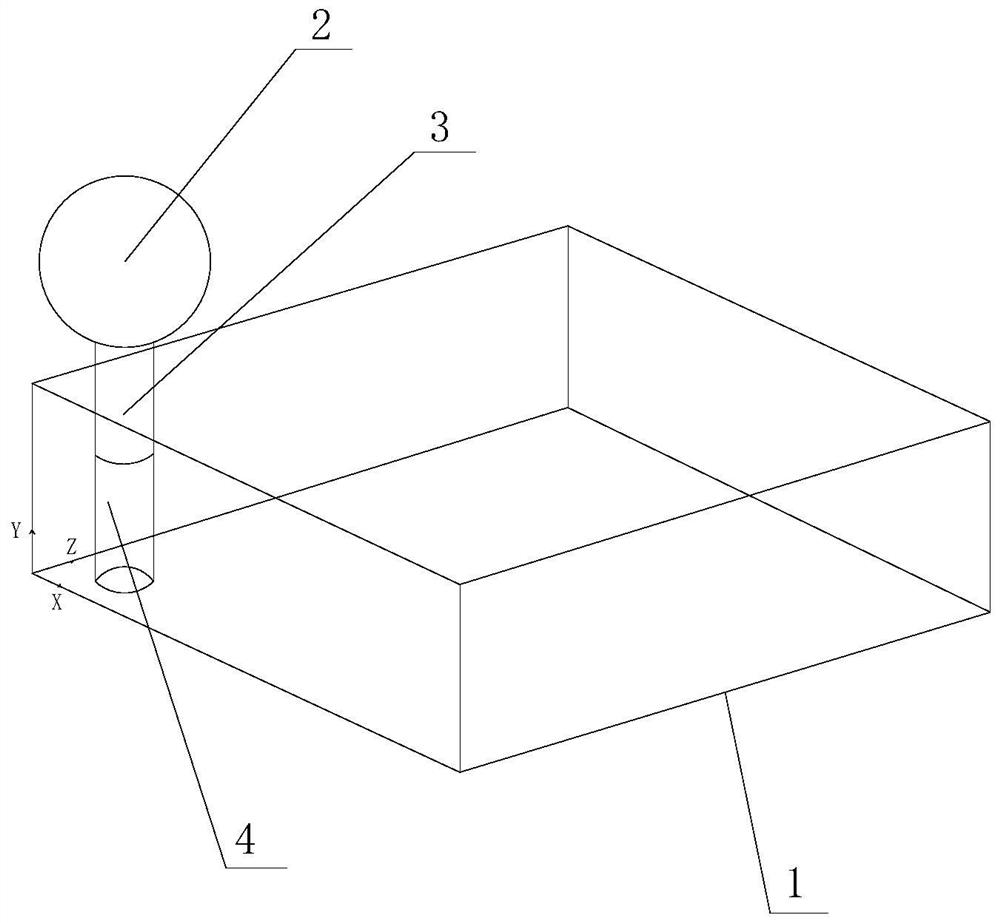

[0025] The aligning tool provided in this embodiment is obtained by improving the existing aligning tool. Specifically, the locating pin on the existing jig plate 1 is removed, and one end of the cylinder 3 at the lower end of the sphere 2 is inserted into the locating hole 4 on the jig plate 1 .

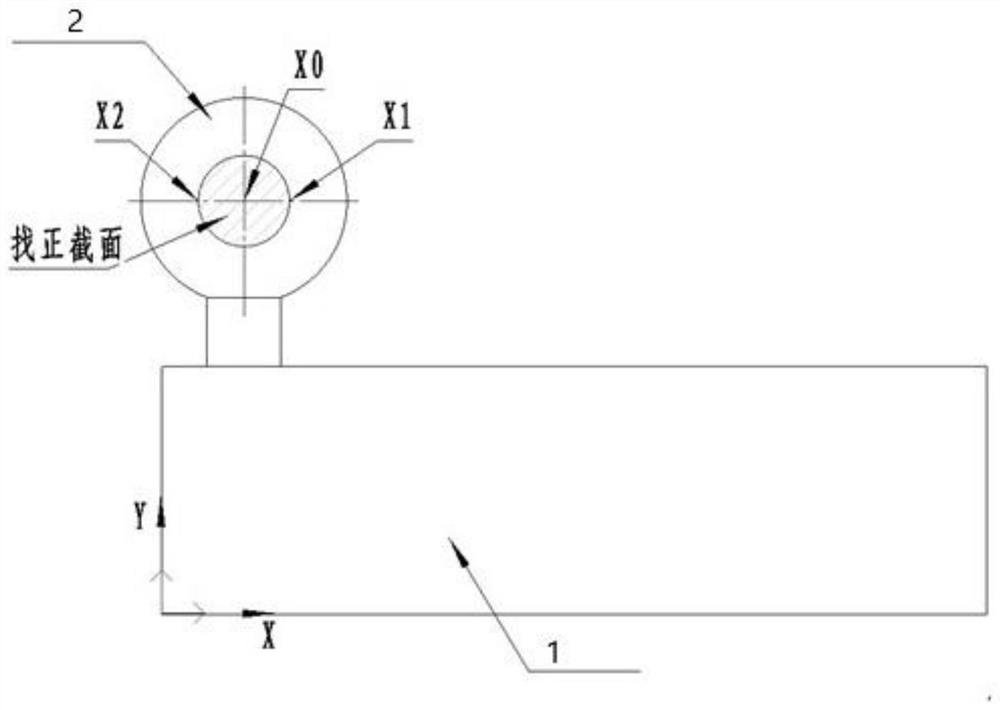

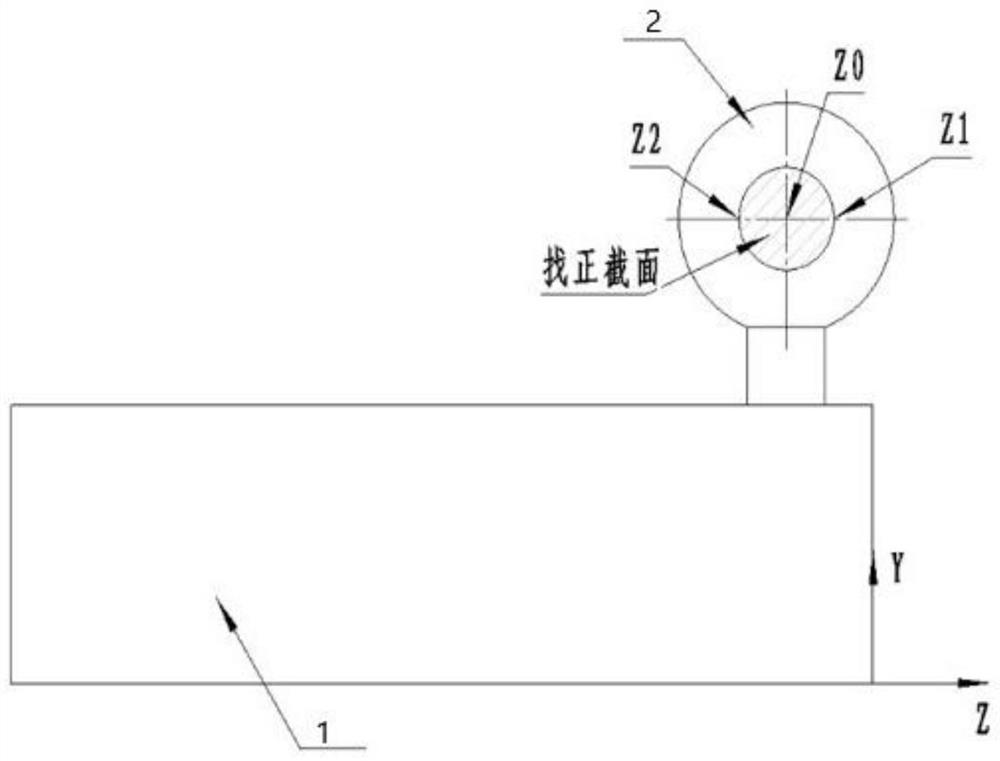

[0026] see figure 1 , the alignment tool provided in this embodiment includes a jig plate 1 and a sphere 2 placed on the surface of the jig plate, a cylinder 3 is arranged between the sphere 2 and the jig plate 1, and the axis of the cylinder 3 and the center of the sphere 1 Coincidentally, the positioning hole 4 is set on the fixture plate 1, which is convenient for clamping the cylinder 3 into the positioning hole 4, and then fixing the sphere 2 on the fixture plate 1. The fixture plate 1 is a square box structure, which is convenient for realizing spatial positioning.

[0027] During implementation, the fixture plate 1 is placed on the workbench for parts processing, the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com