Automatic centering method for end cover of centrifugal compressor

A centrifugal compressor and end cap technology, applied in automatic control devices, metal processing machinery parts, large fixed members, etc., can solve problems such as laborious operation, reduce labor intensity, improve processing efficiency, and reduce alignment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

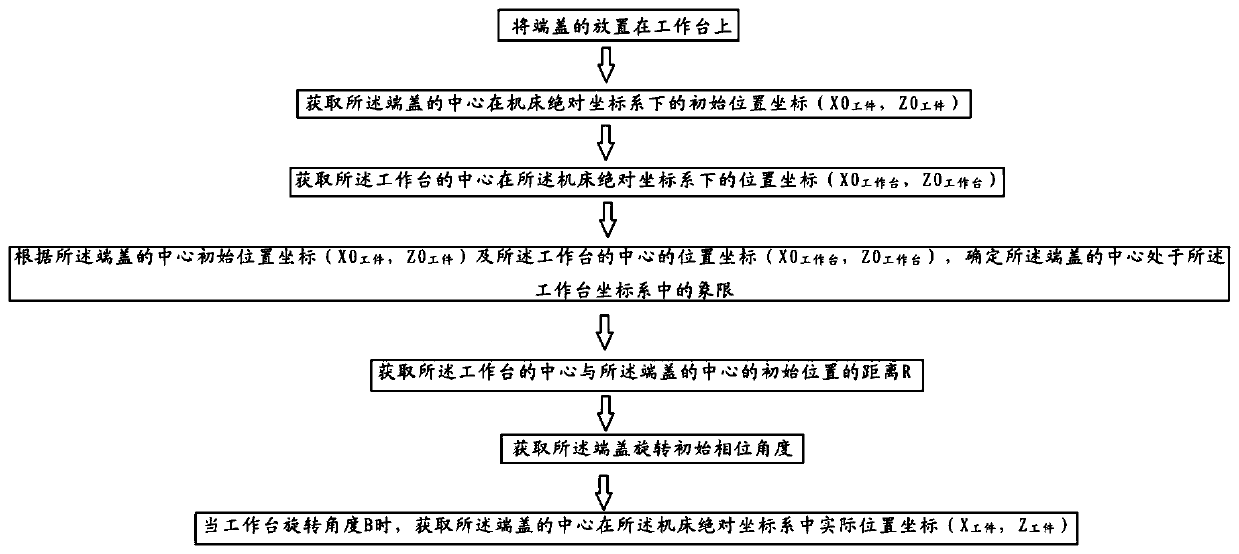

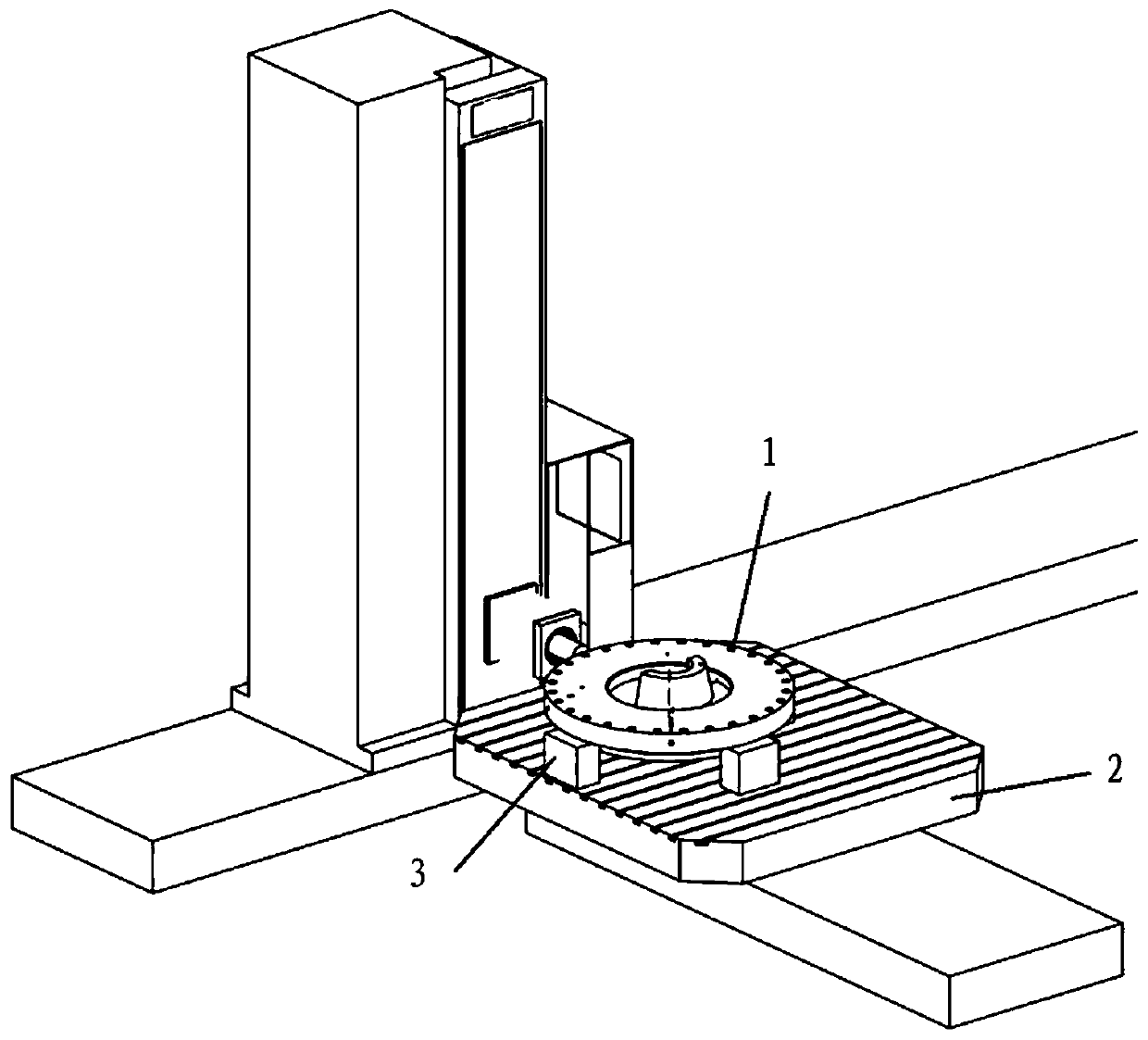

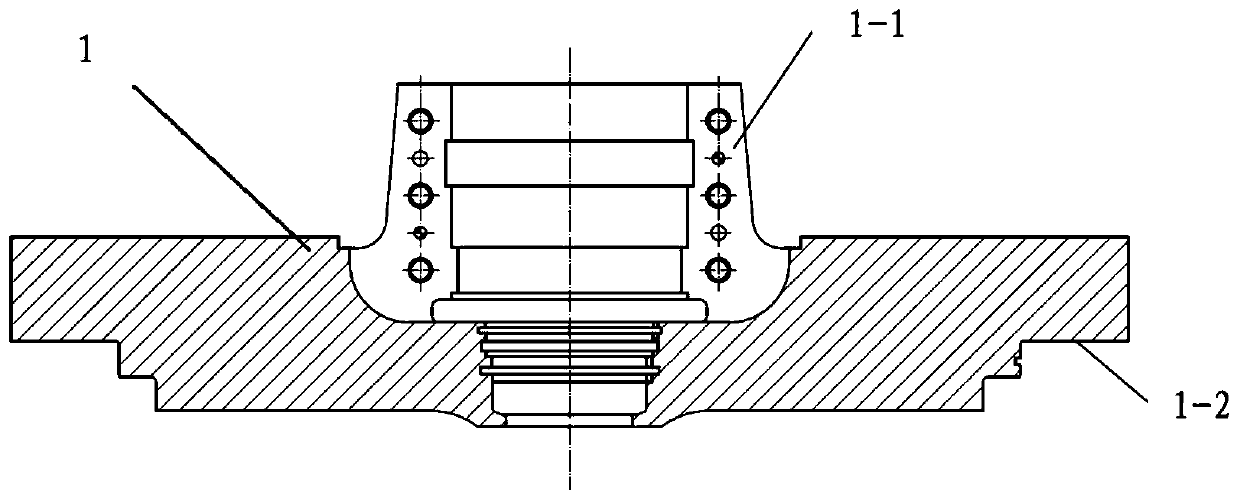

[0020] see Figure 1-3 A method for automatically finding the center of a centrifugal compressor end cover provided by an embodiment of the present invention includes the following steps:

[0021] Step S1 , placing the end cap 1 on the workbench 2 .

[0022] Step S2, obtain the initial position coordinates (X0 工件 , Z0 工件 ).

[0023] Step S3, obtain the position coordinates (X0 工作台 , Z0 工作台 ).

[0024] Step S4, according to the initial position coordinates of the center of the end cap 1 (X0 工件 , Z0 工件 ) and the position coordinates of the center of workbench 2 (X0 工作台 , Z0 工作台 ), determine the quadrant where the center of the end cover 1 is in the workbench coordinate system.

[0025] Step S5, acquiring the distance R between the center of the workbench 2 and the center of the end cover 1 at the initial position.

[0026] Step S6, obtaining the initial phase angle of the rotation of the end cap 1 .

[0027] Step S7, when the workbench 2 is rotated by an angle B, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com