Wafer storage device and automatic material taking and placing equipment with same

A wafer storage, automatic pick and place technology, used in conveyor control devices, packaging, transportation and packaging, etc., can solve problems such as slow product efficiency and personnel damage, improve efficiency, simplify the loading and unloading process, and meet the needs of multiple materials. The effect of box storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings.

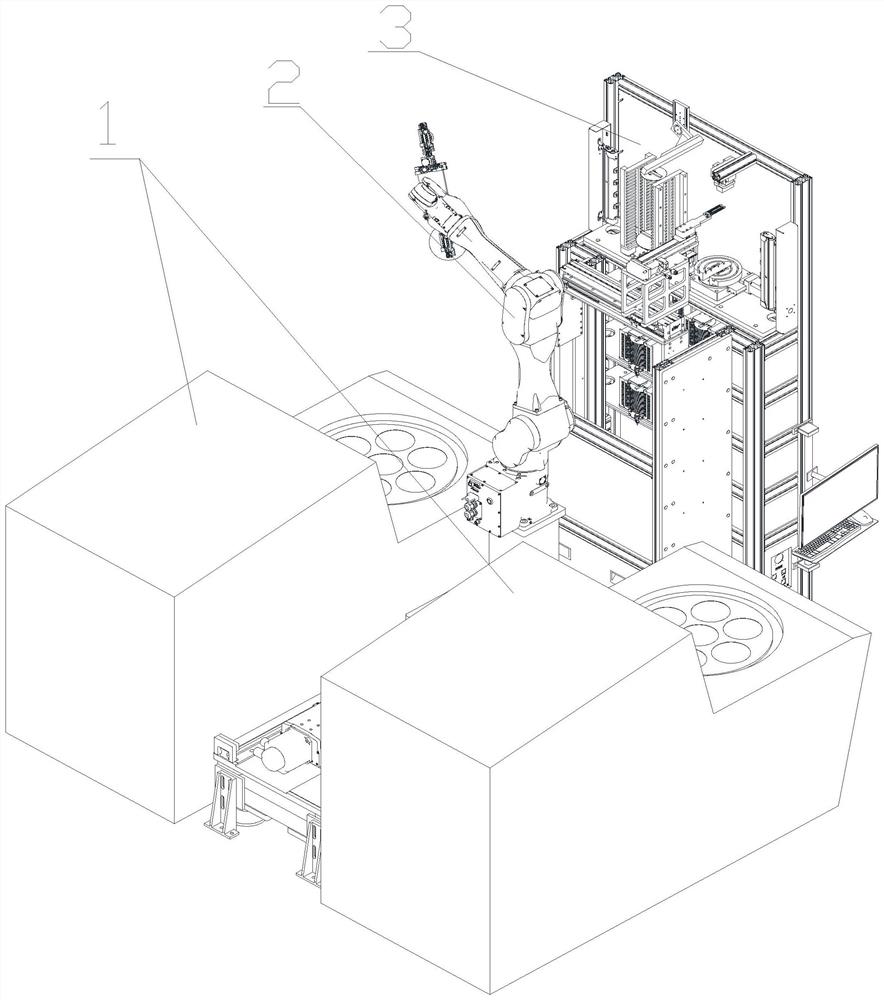

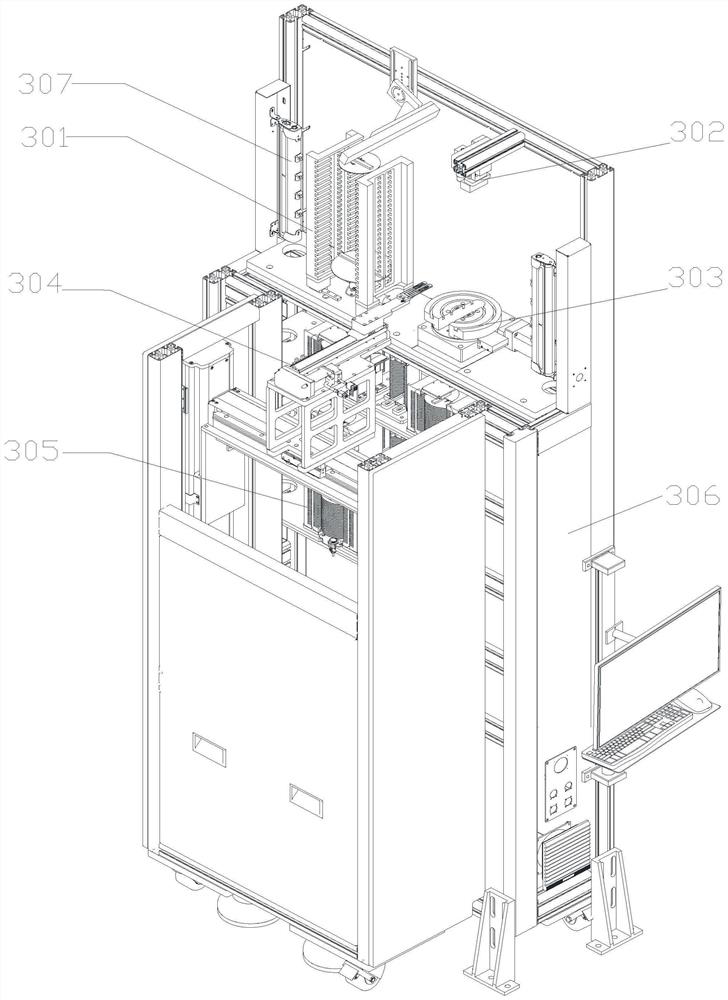

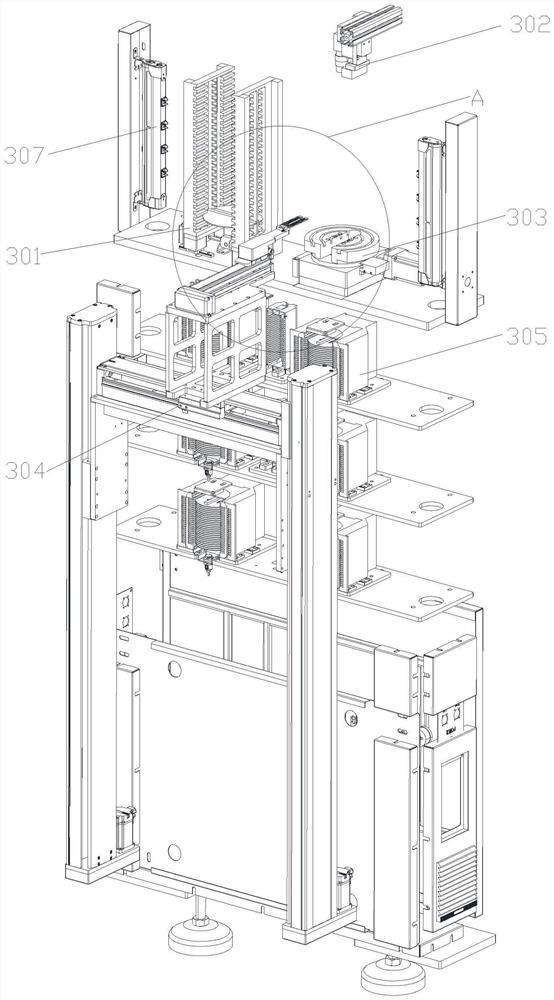

[0030] see Figure 1 to Figure 6 , the present invention provides a wafer storage device 3, including a rack 306, a cooling table 301 for unloading wafers, a transfer table 303 for loading wafers, a three-axis wafer retrieving module 304, and a wafer jam 305; A wafer temporary storage station, a wafer storage station and a wafer heat dissipation station are set in the storage rack 306, and the wafer temporary storage station is installed with the loading wafer transfer station 303, and the wafer storage station The wafer jamming station 305 is installed at the workstation, the wafer unloading wafer cooling table 301 is installed at the wafer cooling station, and the wafer three-axis retrieving module 304 is installed on the rack 306 .

[0031] see Figure 1 to Figure 3 , Figure 5 , in an embodiment of the present invention, ion fans 307 are installed on both sides ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com