Mud scraping equipment for roadbed concrete construction

A technology for concrete and equipment, applied in the field of mud scraping equipment for concrete construction of roadbed, can solve the problems of difficulty in adjusting the mud scraper, unable to meet the needs of use, poor mud scraping effect, etc., and achieve the effect of improving the mud scraping effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

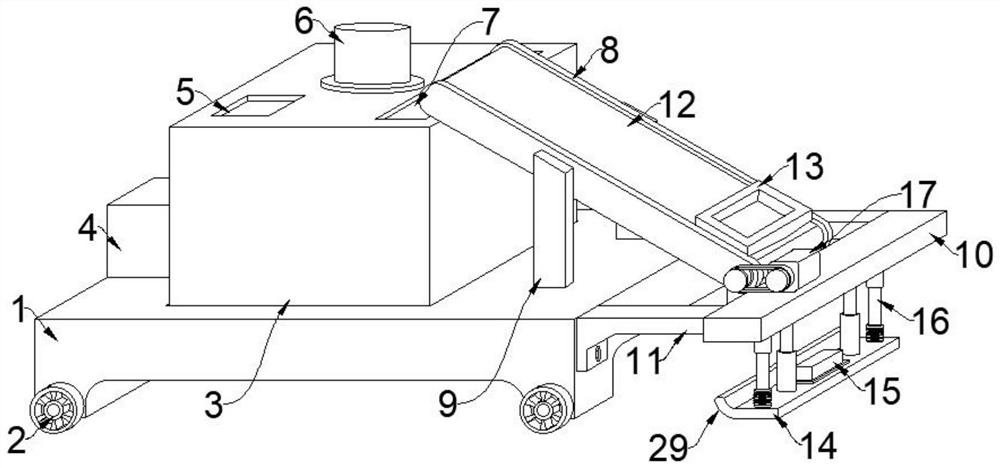

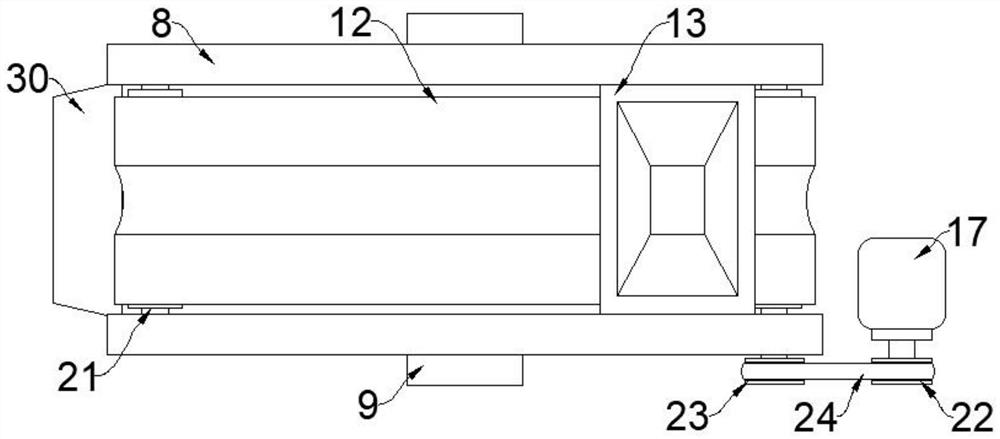

[0029] Such as Figure 1-5 As shown, a mud scraping equipment for roadbed concrete construction includes: an equipment mobile seat 1, a beam plate 10 is provided on one side of the equipment mobile seat 1, and a connection between the beam plate 10 and the equipment mobile seat 1 is provided. The beam frame 11, and the connecting beam frame 11 is connected with the beam plate 10 and the equipment moving seat 1 by screws;

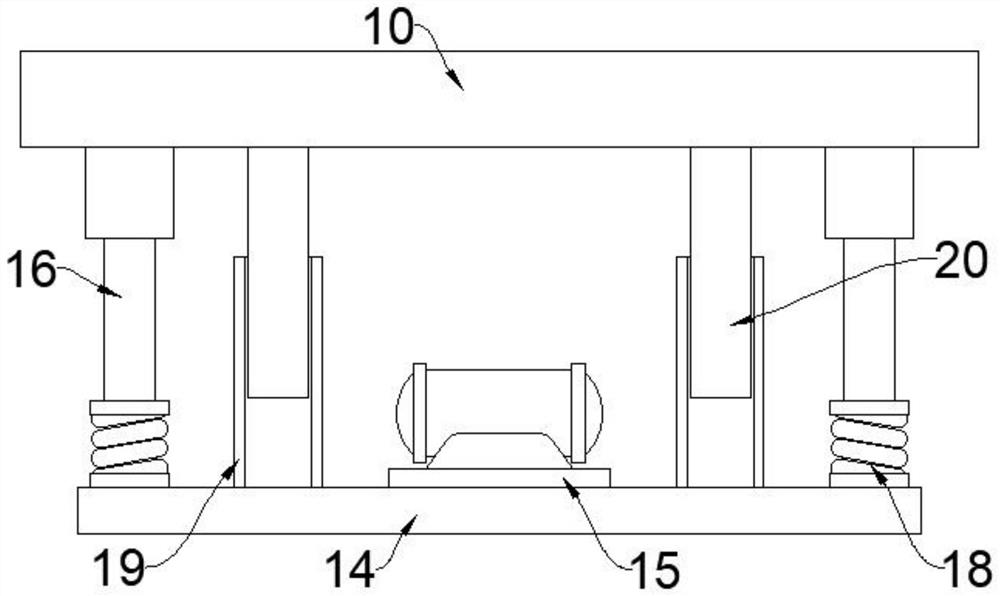

[0030] The mud scraping plate 14, the mud scraping plate 14 is arranged below the beam plate 10, the electric telescopic rod 16 is arranged between the said mud scraping plate 14 and the beam plate 10, two electric telescopic rods 16 are provided, and the electric telescopic rod 16 is connected with the beam plate 10 by screws, and a spring shock abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com