Heat dissipation and cooling device for engine

A cooling device and engine technology, which is applied in the direction of engine components, machine/engine, engine cooling, etc., can solve the problems of large cooling fan power consumption, energy consumption, environmental pollution, etc., and achieve the effect of simple circuit and high intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

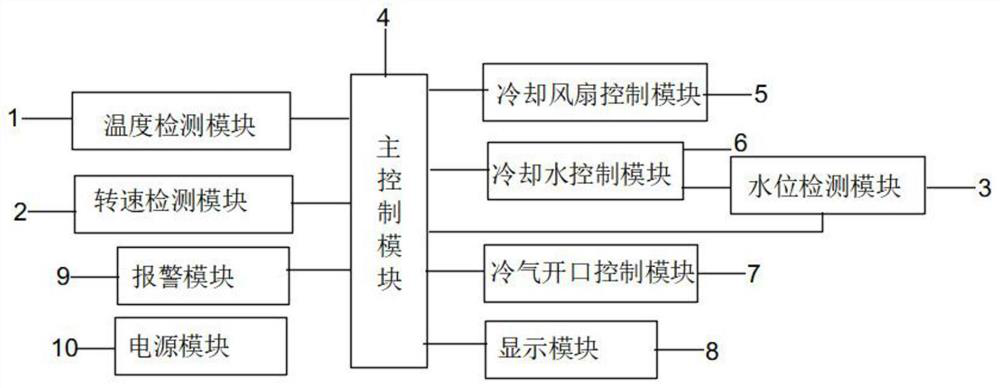

[0018] Embodiment 1: see figure 1 The embodiment of the present invention provides a heat dissipation and cooling device for an engine. The heat dissipation and cooling device for an engine includes: a temperature detection module 1, a rotational speed detection module 2, a water level detection module 3, a main control module 4, and a cooling fan control module 5. Cooling water control module 6, air-conditioning opening control module 7;

[0019] Specifically, the temperature detection module 1 is connected with the main control module 4 for detecting the temperature of the automobile engine and outputting temperature information;

[0020] A rotational speed detection module 2, connected to the main control module 4, for detecting the rotational speed of the cooling fan and outputting rotational speed information;

[0021] The water level detection module 3 is connected with the main control module 4, and is used to detect the cooling water level and output the water level i...

Embodiment 2

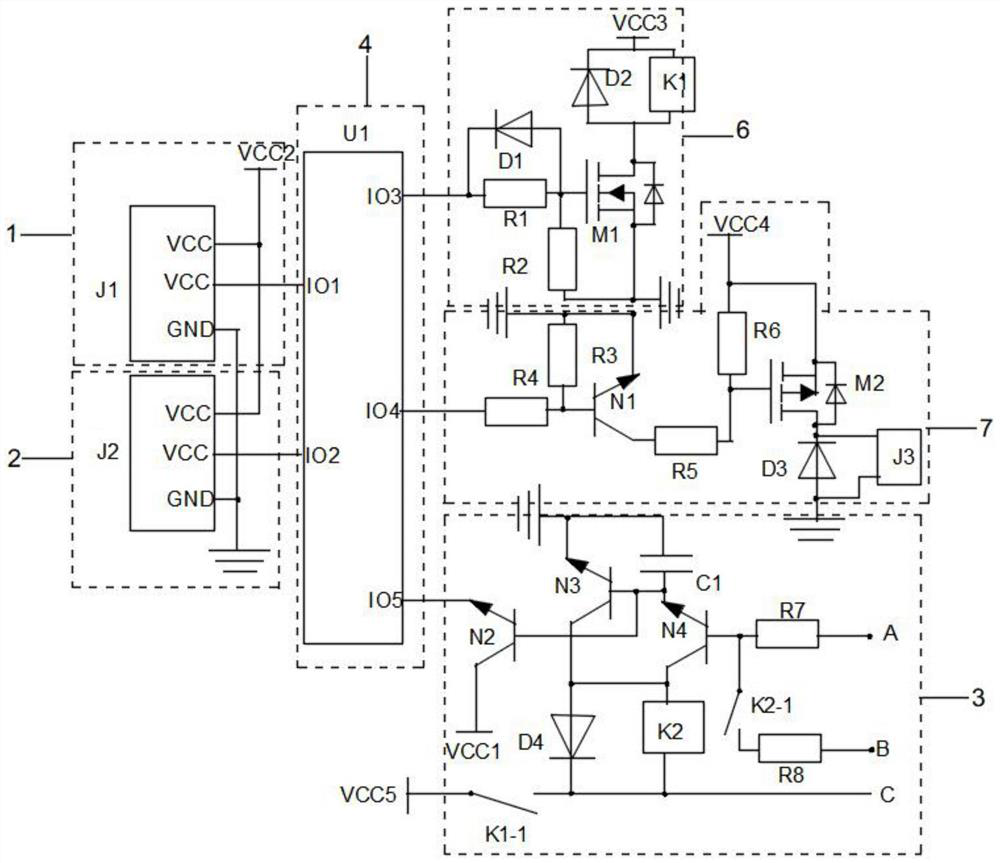

[0032] Embodiment 2: On the basis of Embodiment 1, please refer to figure 2 , in a specific embodiment of the engine heat dissipation and cooling device described in the present invention, the temperature detection module 1 includes a temperature sensor J1; the speed detection module 2 includes a speed sensor J2; the power module 10 includes a second power supply VCC2 ; The main control module 4 includes a first controller U1;

[0033] Specifically, the power supply terminal of the temperature sensor J1 and the power supply terminal of the rotational speed sensor J2 are both connected to the second power supply VCC2, the ground terminal of the temperature sensor J1 and the ground terminal of the rotational speed sensor J2 are both grounded, and the output terminal of the temperature sensor J1 and The output terminals of the rotational speed sensor J2 are respectively connected to the first IO terminal and the second IO terminal of the first controller U1.

[0034] Further, t...

Embodiment 3

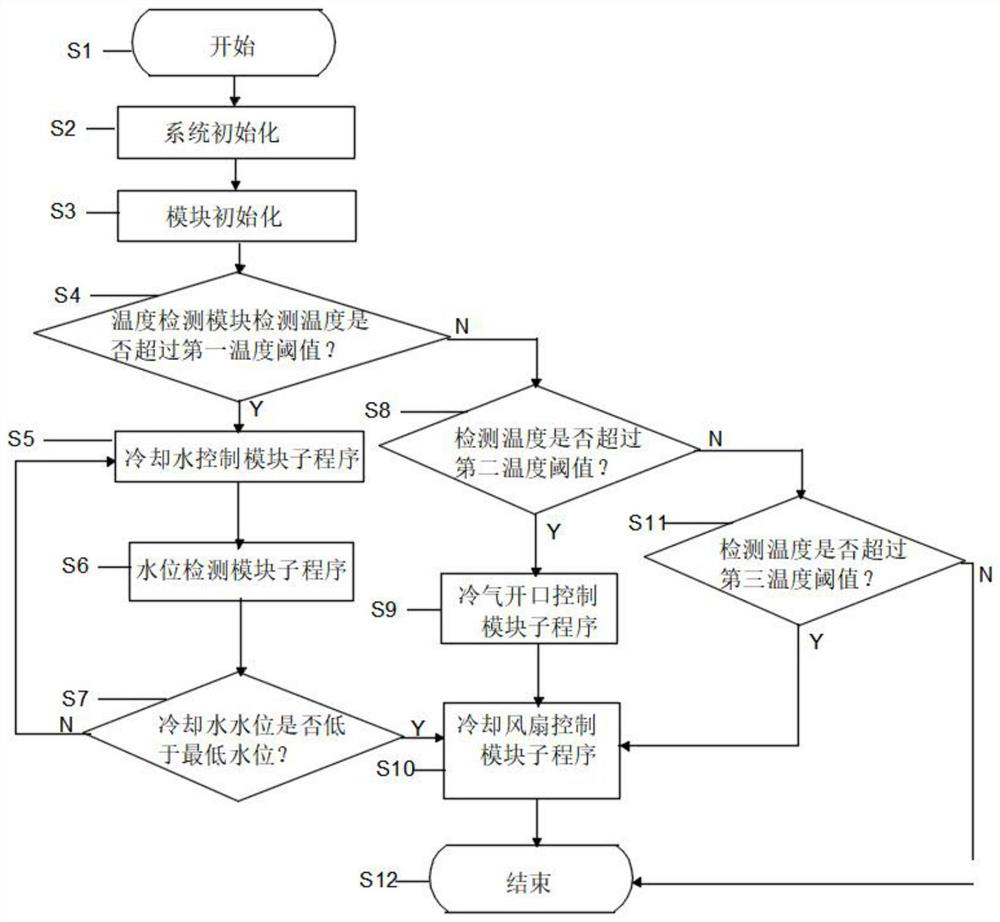

[0042] Embodiment 3: On the basis of Embodiment 2, please refer to image 3 , in a specific embodiment of a heat dissipation and cooling device for an engine according to the present invention, the specific steps of the workflow of each module are as follows:

[0043] S1, start;

[0044] S2, device initialization;

[0045] S3, module initialization;

[0046] S4, the temperature detection module 1 detects whether the temperature exceeds the first temperature threshold, if so, enters S5, otherwise enters S8;

[0047] S5, 6 subroutines of the cooling water control module, used to control the work of the cooling water module;

[0048] S6, water level detection module 3 subroutines, used to detect the water level situation in the cooling water tank;

[0049] S7. Whether the cooling water level is lower than the minimum water level, if yes, enter S10, otherwise, enter S5;

[0050] S8. Detect whether the temperature exceeds the second temperature threshold, if yes, enter S9, oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com