Cleaning head, cleaning device and cleaning method

A technology of cleaning equipment and cleaning head, which is applied in the direction of cleaning equipment, vacuum cleaners, household utensils, etc., to achieve the effect of quick cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

application example 1

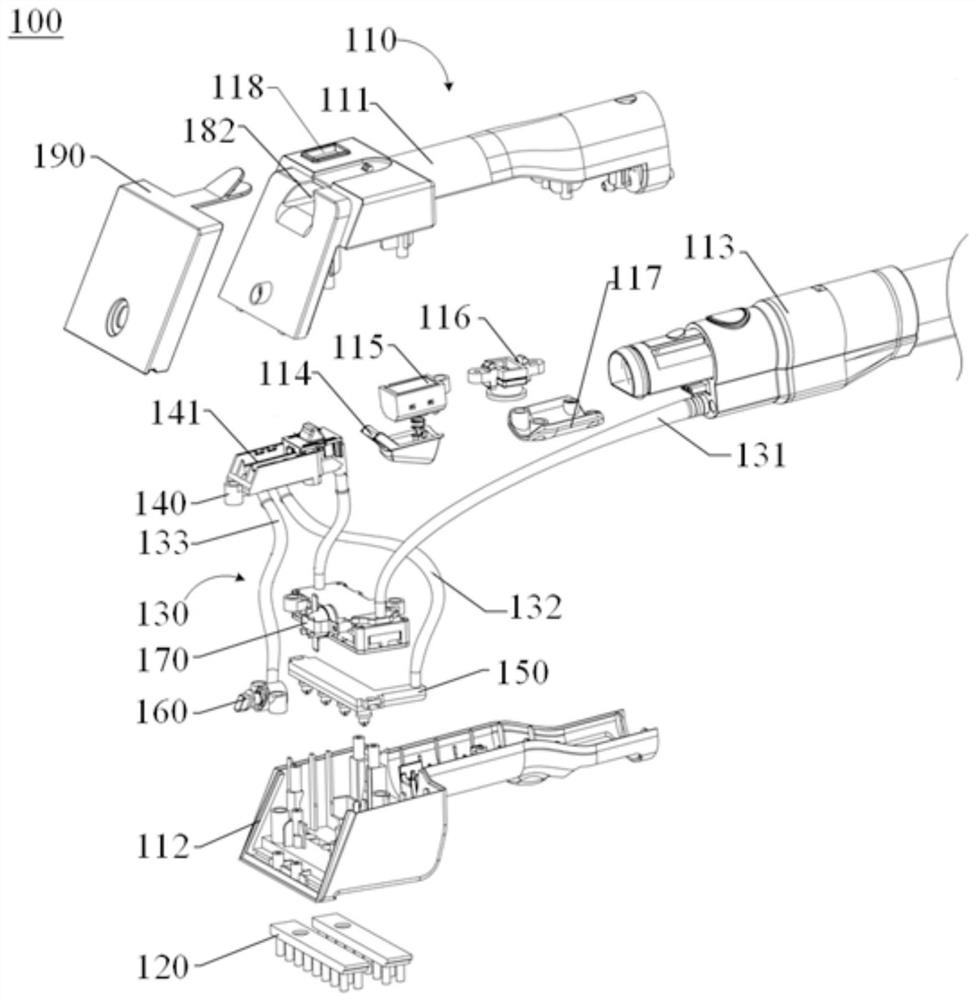

[0086] In Application Example 1, a cleaning head 100 is provided, which can be installed in various types of cleaning equipment such as vacuum cleaners, mite removing machines, carpet and curtain cleaning machines, cleaning robots, etc., where the types of cleaning equipment in this application example Not specifically limited. The cleaning head 100 includes a body 110, a cleaning piece 120, a distribution pipeline 130, a distribution device 140, a first spray device 150 and a second spray device 160, wherein the distribution pipeline 130, the distribution device 140 and At least one of the second spraying devices 160 has a speed-increasing structure, and the speed-up structure enables the cleaning medium to flow in the second spraying device 160 compared with that in the first spraying device. 150 has a larger outlet flow rate, and the second spray device 160 can be used for fixed-point cleaning of stubborn stains.

application example 2

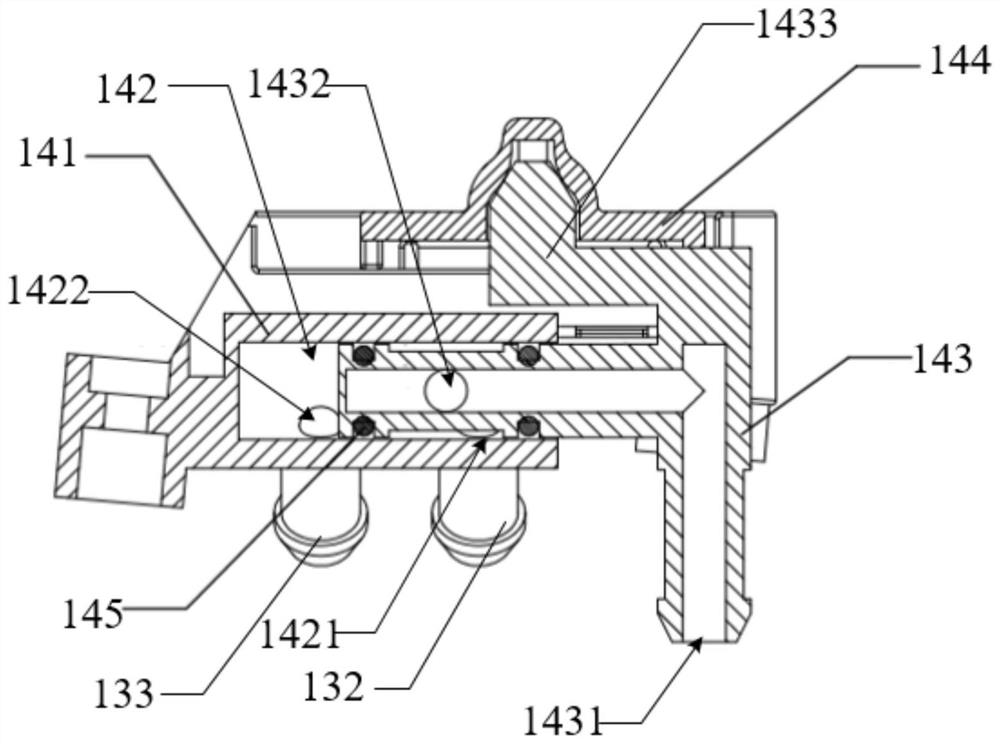

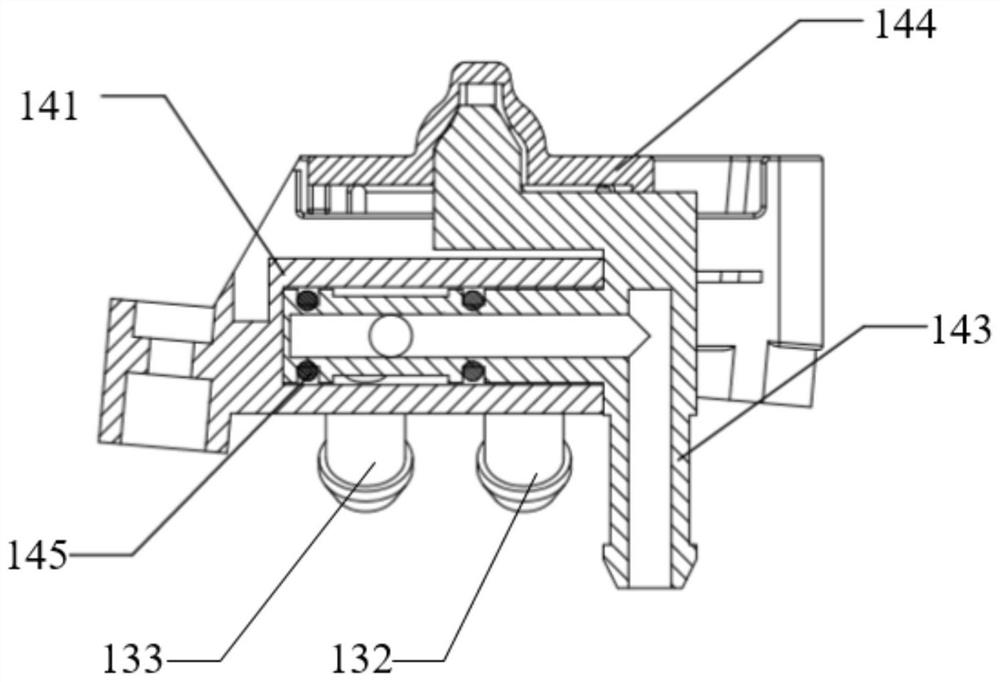

[0088] In the second application example, the structure of the cleaning head 100 is substantially the same as that in the first application example, the difference being that the distribution device 140 in this application example specifically includes a distribution seat 141 and a switching member 143 . Wherein, the distribution base 141 has a distribution cavity 142, and the distribution cavity 142 has a first interface 1421 and a second interface 1422, the first interface 1421 communicates with the first spray device 150, and the second The interface 1422 is connected to the second spraying device 160; the switching member 143 has an inlet port 1431 and an outlet port 1432, and the inlet port 1431 is used for receiving cleaning medium. Here, when the switching member 143 is located at the first position, the cleaning medium may be supplied to the first shower device 150 . When the switching member 143 is in the second position, the cleaning medium can be supplied to the sec...

application example 3

[0090] In the third application example, the structure of the cleaning head 100 is substantially the same as that in the first application example, the difference is that the first spray device 150 specifically includes a plate-shaped spray seat 152, the spray A medium flow channel is arranged inside the seat 152 and several first spray ports 151 communicated with the medium flow channel are arranged on its surface, and the first spray ports 151 are evenly spaced so as to achieve a uniform spray effect. The second shower device 160 only includes a second shower port 161 . The first shower device 150 has a larger coverage area than the second shower device 160 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com