Gas supply system of compressed natural gas vehicle

A technology for compressing natural gas and gas supply system, which is applied in vehicle components, layout combined with internal combustion engine fuel supply, power plant, etc. The effect of avoiding the impact of strength, reducing the risk of leakage and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to enable those skilled in the art to better understand the technical solution of the present invention, the solution will be further described in detail below in conjunction with specific embodiments.

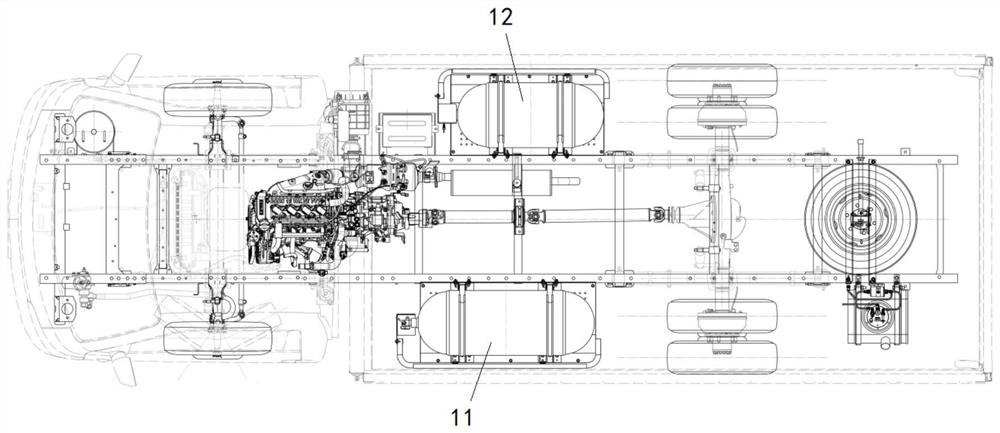

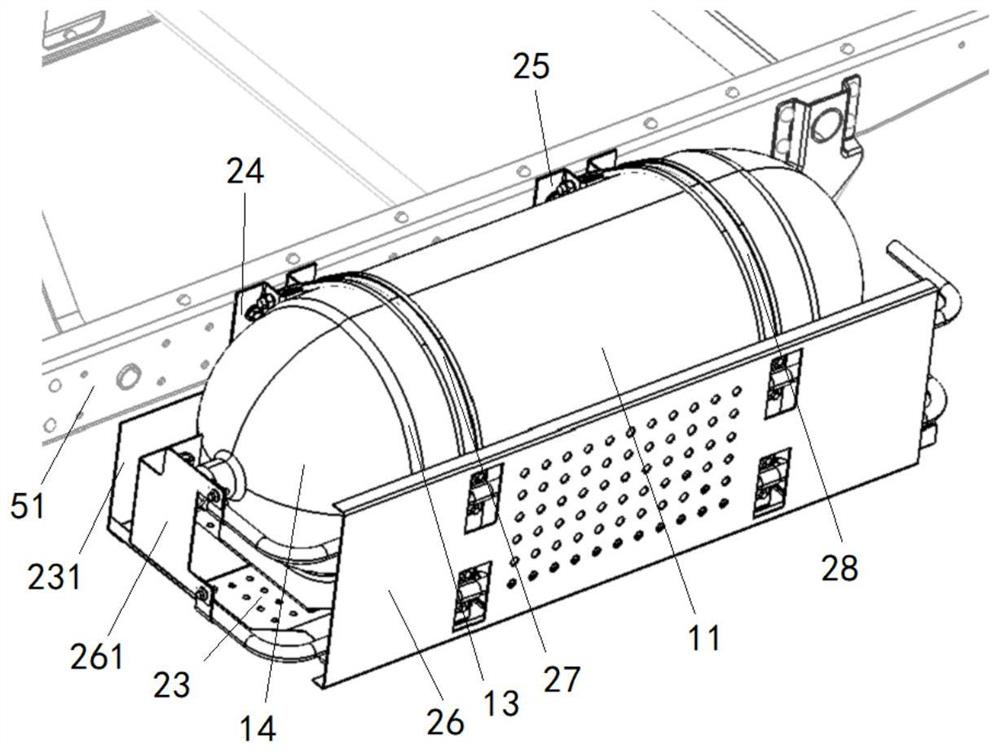

[0052] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a gas supply system for a compressed natural gas vehicle, which includes a compressed gas cylinder device, a refueling device 31, and a pressure reducer 41. The compressed gas cylinder device includes a first gas cylinder 11 and a second gas cylinder. Two gas cylinders 12, the first gas cylinder 11 and the second gas cylinder 12 are respectively arranged on both sides of the vehicle frame 51 middle position below the cargo box of the vehicle and close to the engine of the vehicle; The second gas bottle 12 is connected to the gas filling device 31 respectively, one end of the pressure reducer 41 is connected to the gas filling device 31, and the other end of the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com