Circular knitting machine transfer pickup device and pickup method

A technology of circular knitting machine and pick-up device, which is applied in knitting, weft knitting, textiles and papermaking, etc. It can solve the problems of complex structure of transfer pick-up device, radial position of deformed needle cylinder, grasping missing knitting loops, etc. Achieve compact structure, prevent accidental detachment, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

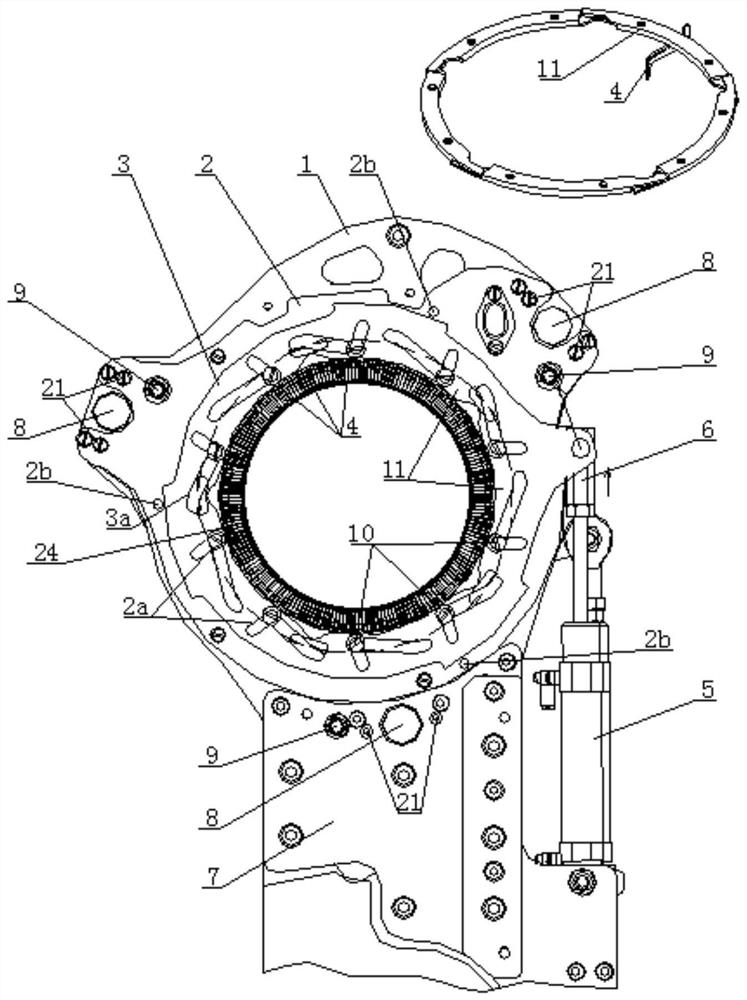

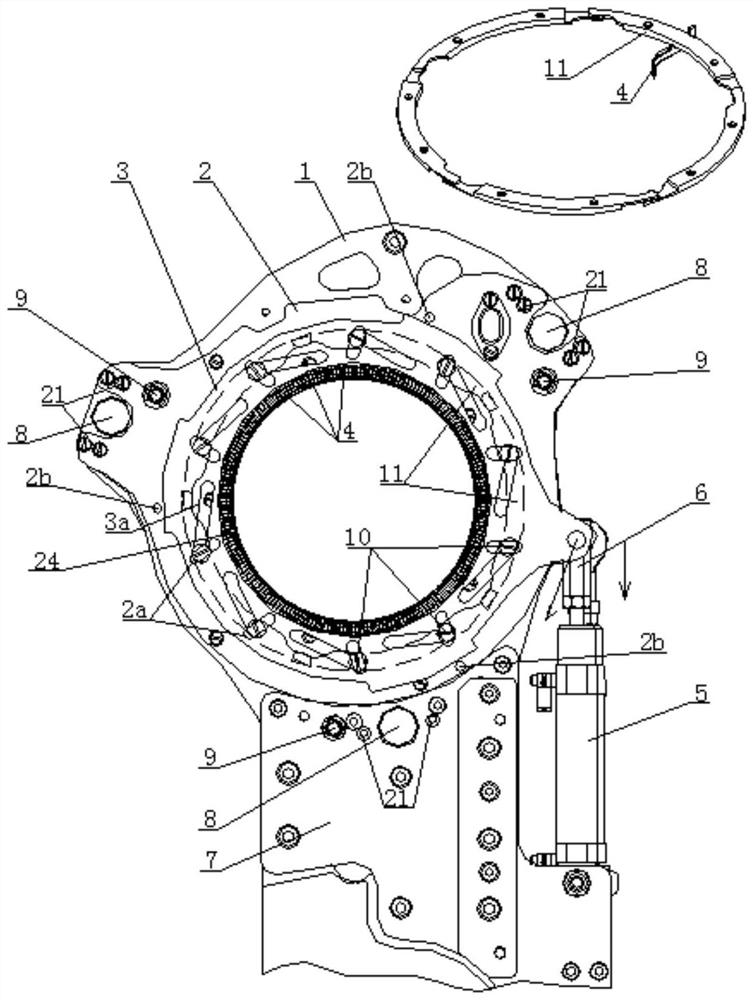

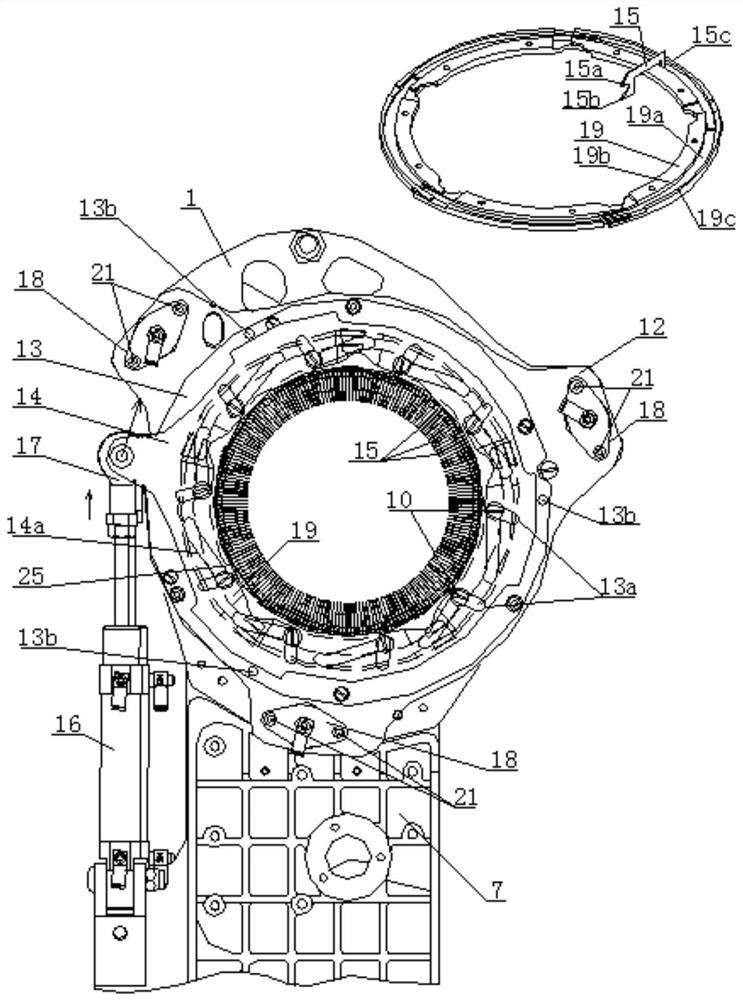

[0030] refer to Figure 1 to Figure 17 The specific implementation of a circular knitting machine transfer pick-up device and pick-up method of the present invention will be further described.

[0031] A transfer pick-up device for a circular knitting machine, comprising a catch assembly, a catch assembly is arranged below the catch assembly, the catch assembly and the catch assembly are arranged in concentric circles, the catch assembly and the catch assembly The grasping assembly is respectively provided with a plurality of corresponding radially movable trocar needles 4 and grasping pieces 15, and a shaft is arranged between the trocar assembly and the grasping assembly to drive them to move up and down relative to each other. to the drive unit.

[0032] The transfer pick-up device includes a set of set up and down sets of sets and grasping components, grasping components can move up and down axially relative to the sets of sets of sets, the set of set needles 4 is sliding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com