Turbine test bed of aero-engine under high altitude and low Reynolds number, simulation method and application

An aero-engine, low Reynolds number technology, used in jet engine testing, gas turbine engine testing, etc., can solve problems such as the inability to select turbine test systems, achieve fast and accurate model selection, and improve work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

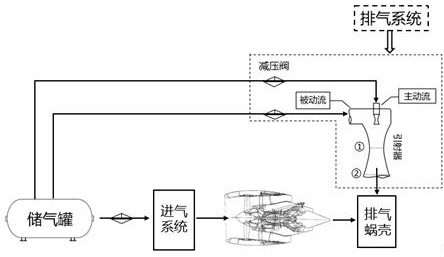

[0023] refer to figure 1 , an aero-engine turbine test bench at high altitude and low Reynolds number provided by an embodiment of the present invention, the test bench includes: mainly including an air intake system, an ejector active flow input port and a passive flow input port, a pressure reducing valve and an ejector The tester body; the test gas is provided by the high-pressure gas in the gas storage tank. Since the air intake system, the pressure required by the active flow and the passive flow of the ejector are different, different pressure reducing valves are required, and different test conditions require Different flow rates, so the opening of the pressure red...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com