Highly wear-resistant packaging box

An anti-wear, packaging box technology, used in packaging, transportation and packaging, containers to prevent mechanical damage, etc., can solve the problems of insufficient packaging box cover, hand scratching, broken packaging box, etc., to achieve no longer appearance. Beautify, avoid scratches, improve the effect of wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] For the technical means that the present invention realizes, creative feature, reach purpose and effect are easy to understand, the present invention will be further described below in conjunction with embodiment:

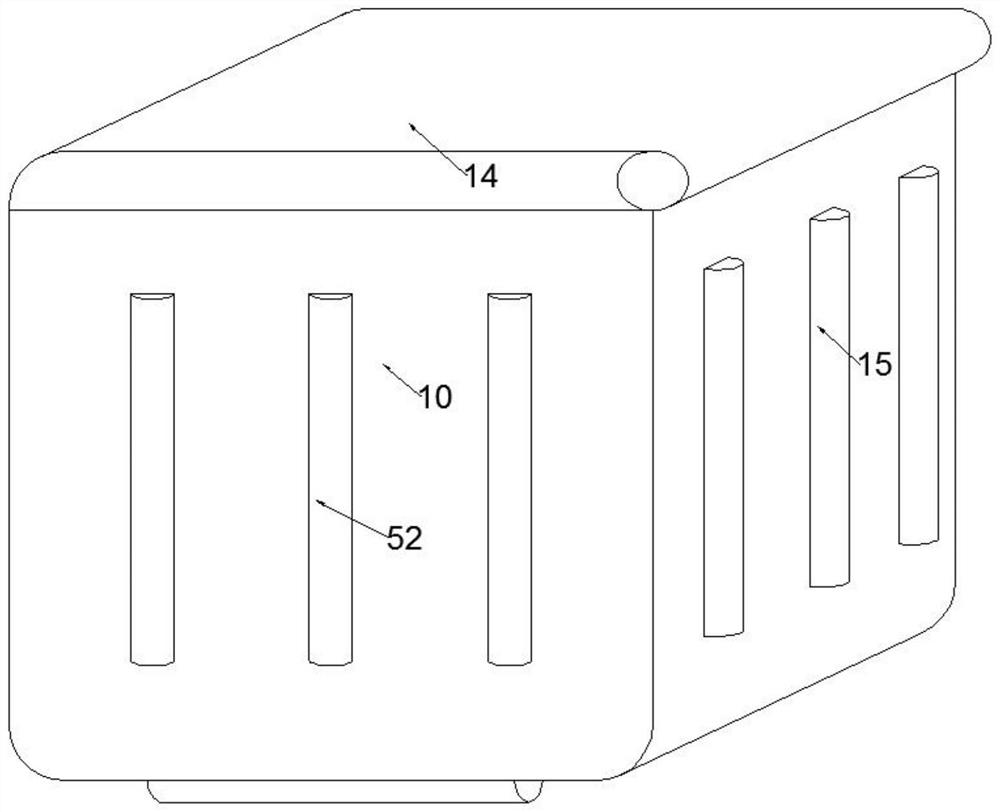

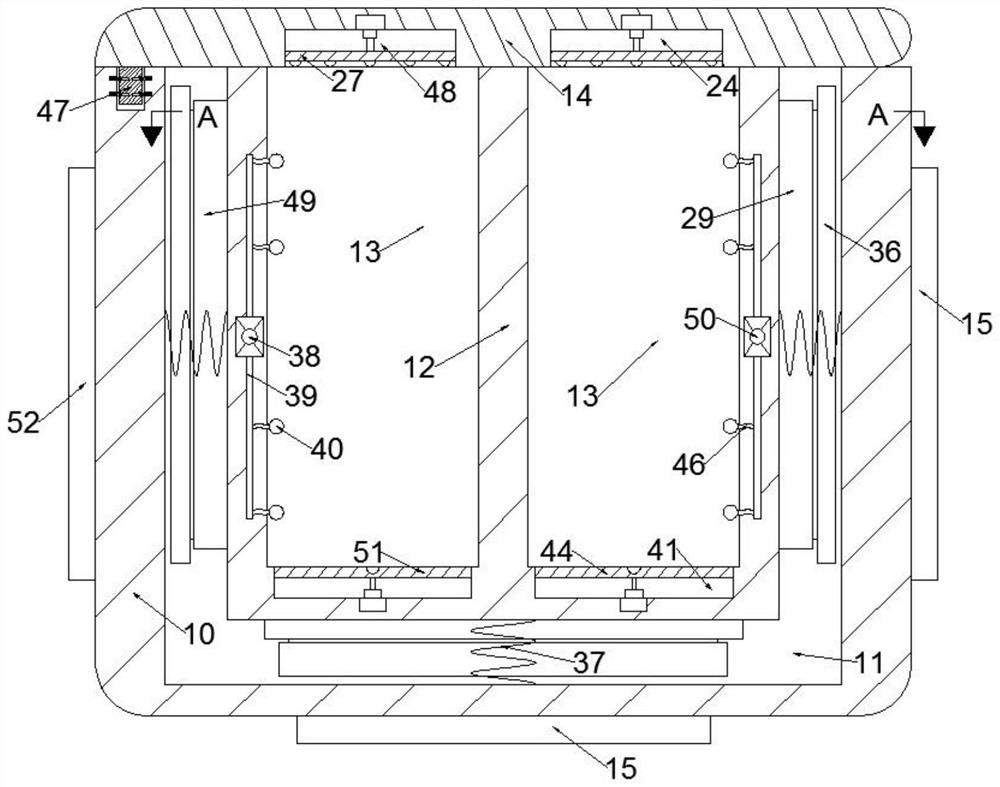

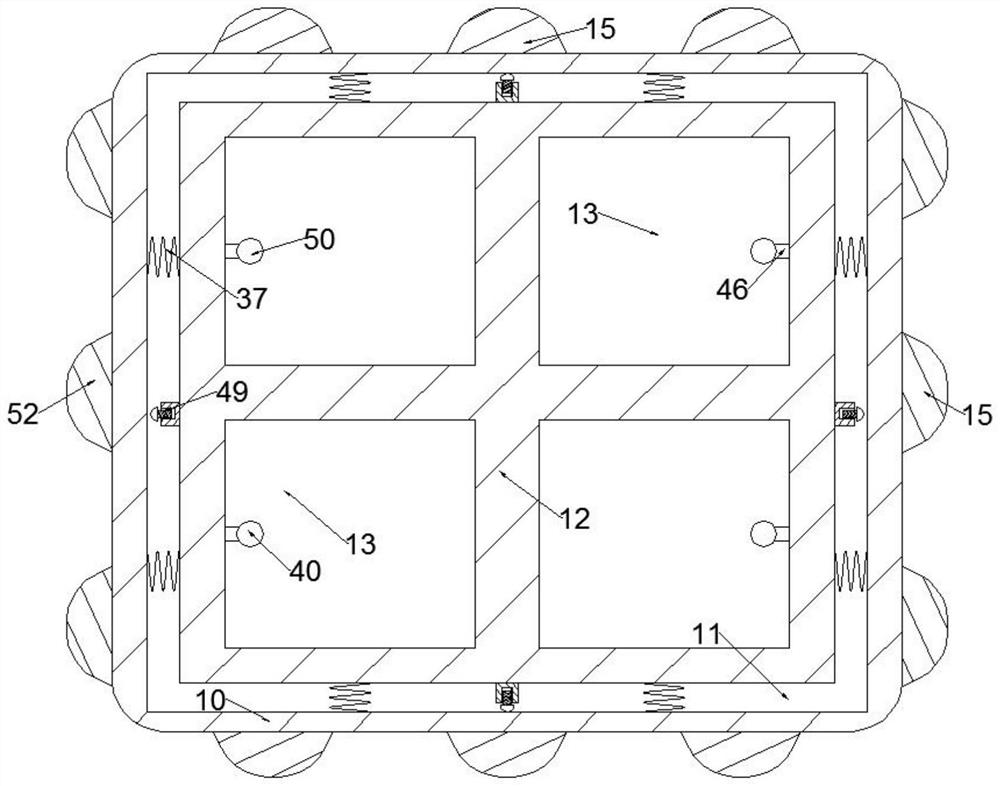

[0041] Refer to attached Figure 1-Figure 8 The shown highly wear-resistant packaging box includes an outer shell 10, and the outer shell 10 is provided with an active chamber 11 with an upward opening, and an inner shell 12 is slidably connected to the inner shell 11, and the inner shell 12, etc. There are four storage cavities 13 with upward openings at intervals, a cover plate 14 is rotatably connected to the top wall of the housing 10, and a buckle device 47 is provided on the left bottom wall of the cover plate 14;

[0042] Four first extrusion devices 48 corresponding to the storage chamber 13 are arranged at equal intervals in the wall of the cover plate 14;

[0043] A protection device 50 is provided on the side wall of the storage cavity 13 away fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com