Shock pad, step chain wheel with shock pad and escalator adopting chain wheel

A step sprocket and shock absorbing pad technology, which is applied to escalators, springs/shock absorbers, vibration suppression adjustments, etc., can solve the problem of unsatisfactory shock absorption effect of shock absorbing pads, permanent deformation of shock absorbing pads, and short service life and other problems, to achieve the effect of strong elastic deformation ability, good cushioning performance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

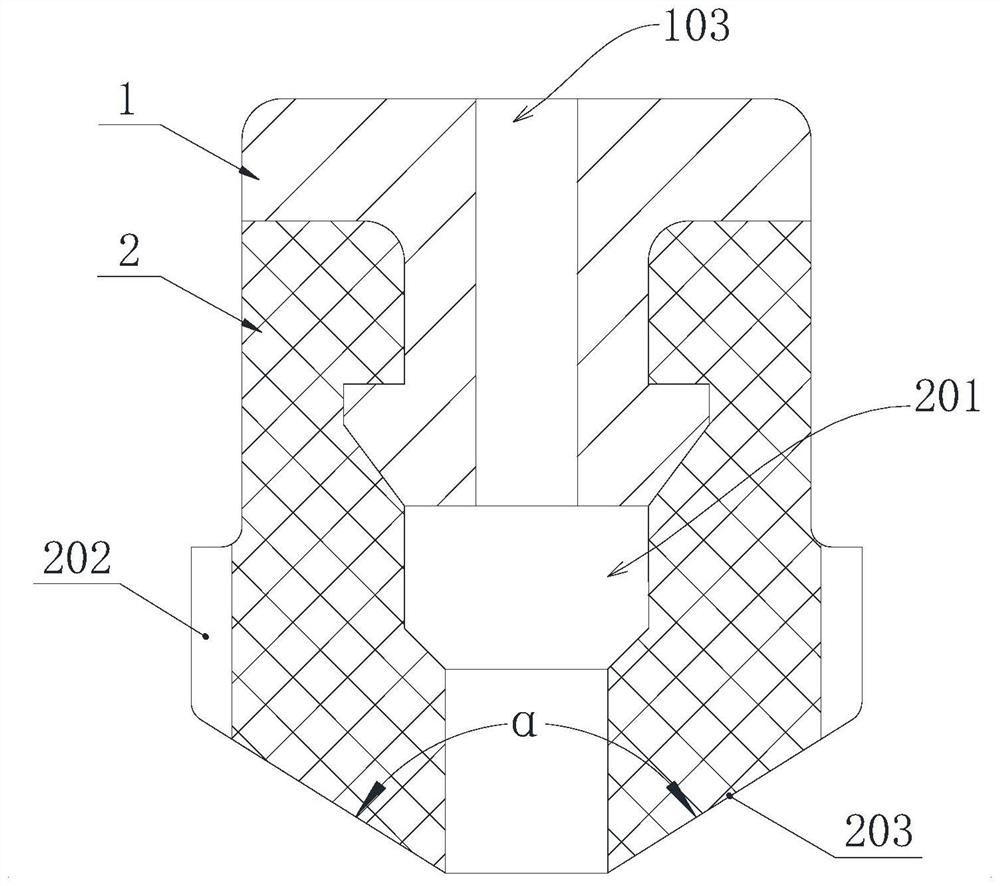

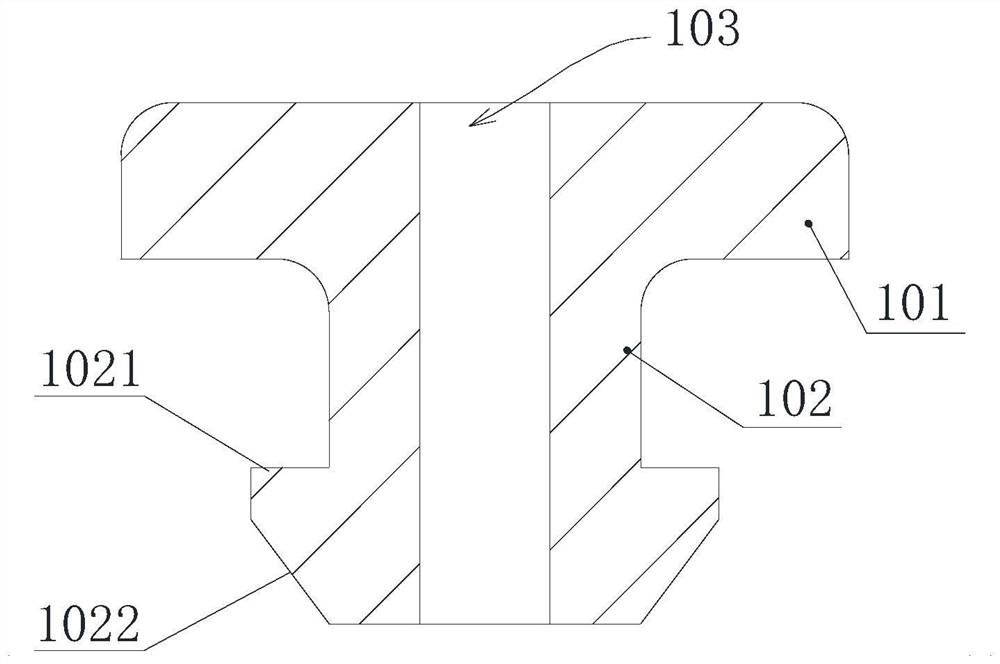

[0024] In this embodiment, a step is provided on the connecting portion 102 to form a barb 1021 . The barb 1021 provided on the connecting part 102 can improve the bonding strength between the hard wear-resistant core 1 and the elastic rubber plug 2, avoiding the phenomenon that the hard wear-resistant core 1 and the elastic rubber plug 2 are detached during use, and improves the wear resistance. The reliability of the shock pad further prolongs its service life. Further, the connecting portion 102 has a first inclined step surface 1022 that is inclined inwardly and converges at the position below the barb 1021 , forming a rounded platform structure. Setting a convergent structure under the barb 1021 can further improve the bonding strength between the elastic rubber plug 2 and the hard wear-resistant core 1, and after the hard wear-resistant core 1 converges, the radial dimension becomes smaller, so that the elastic rubber plug 2 can The radial thickness of the position can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com