Oval beam plane construction paying-off method

An elliptical and flat technology, which is applied in the field of elliptical beam plane construction setting out, can solve the problems of construction lofting scheme without elliptical beams, plumb weight swinging back and forth error, and unevenness of the first floor, so as to improve the setting out construction Efficiency, accurate positioning and checking, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

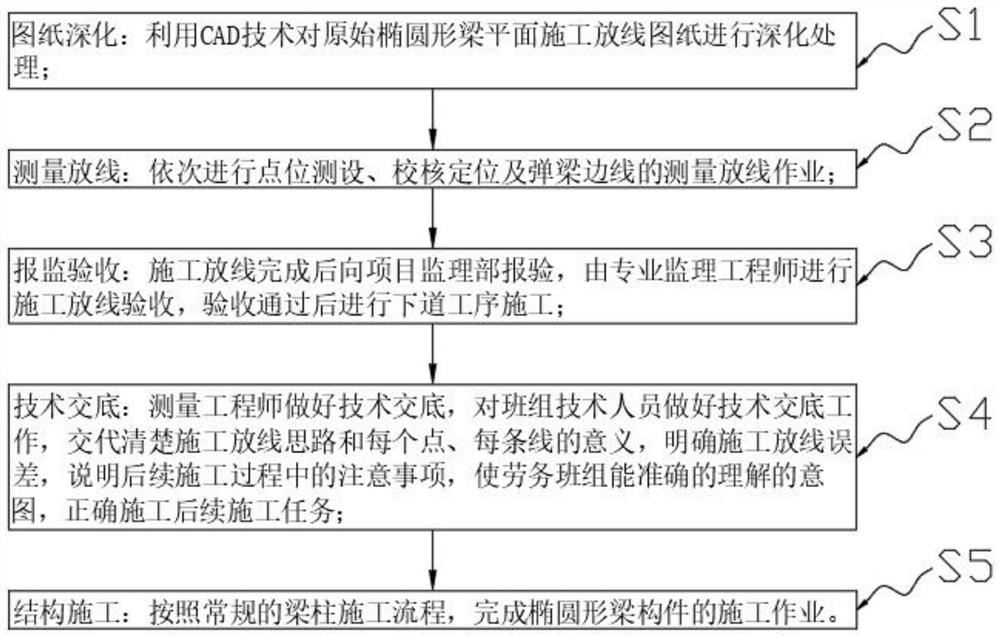

[0046] Such as Figure 1-Figure 9 As shown, this embodiment provides a method for laying out wires in plane construction of elliptical beams, including the following steps:

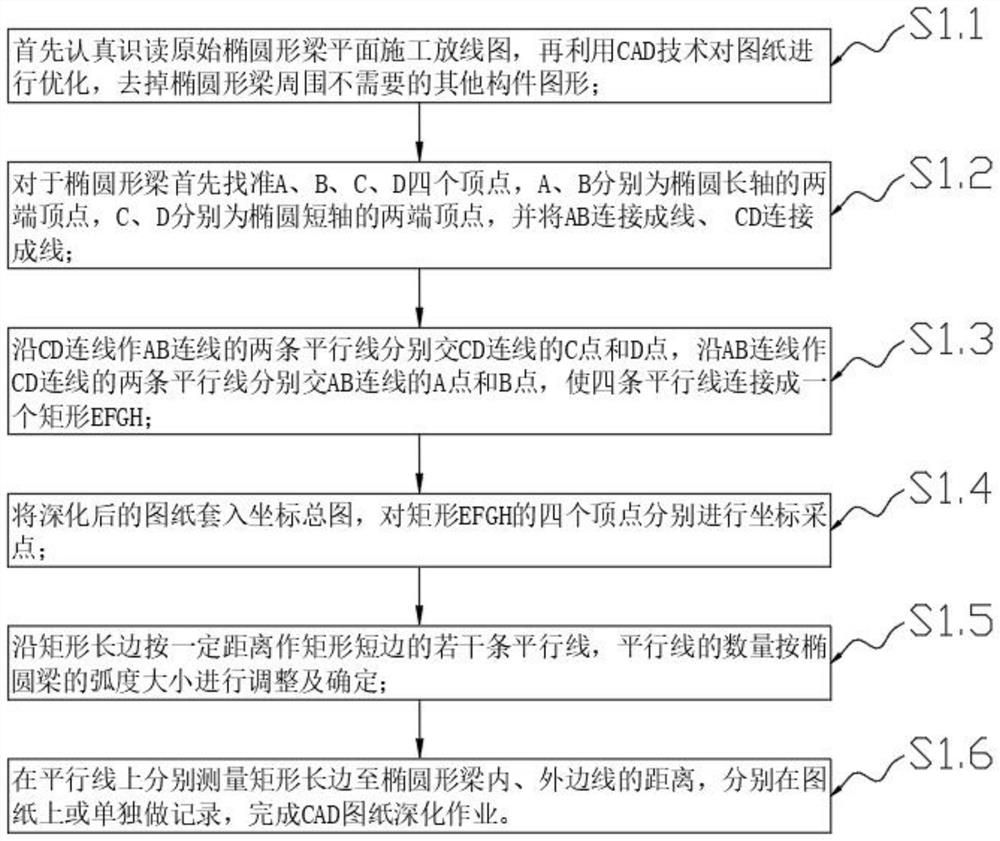

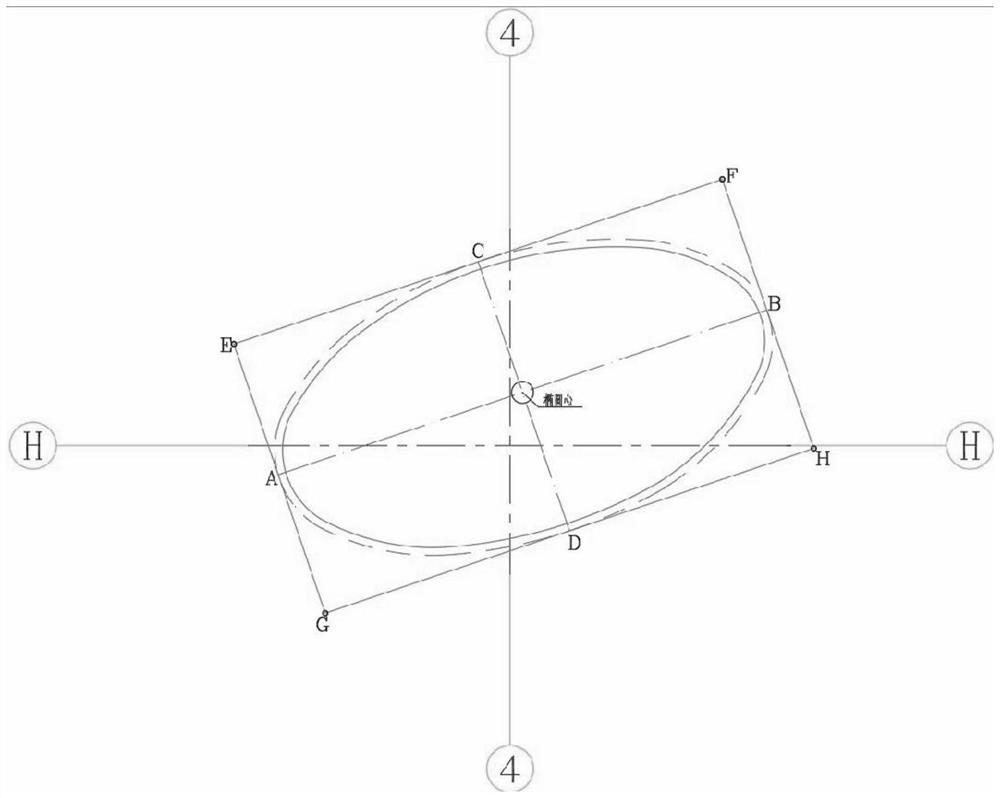

[0047] S1. Drawing deepening: use CAD technology to deepen the original elliptical beam plane construction drawing;

[0048] S2. Measuring and setting out: carry out point measurement and setting, checking and positioning and measuring and setting out of the sideline of the beam in sequence;

[0049] S3. Reporting to the supervisor for acceptance: after the completion of the construction setting-out, report to the project supervision department for inspection, and the professional supervision engineer will conduct the construction setting-out acceptance, and the next process will be carried out after the acceptance is passed;

[0050] S4. Technical clarification: The surveying engineer should do a good job of technical clarification, and do a good job of technical clarification to the team technicians, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com