Aviation fuel quantity sensor measuring circuit based on triangular wave automatic windowing mechanism

A technology for measuring circuits and aviation oil, which is applied in the direction of engine lubrication, measuring devices, engine components, etc., can solve the problems of complexity, distribution parameters, and the inability to continue to improve the accuracy of aircraft fuel measurement, so as to reduce signal voltage fluctuations, The effect of improving measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

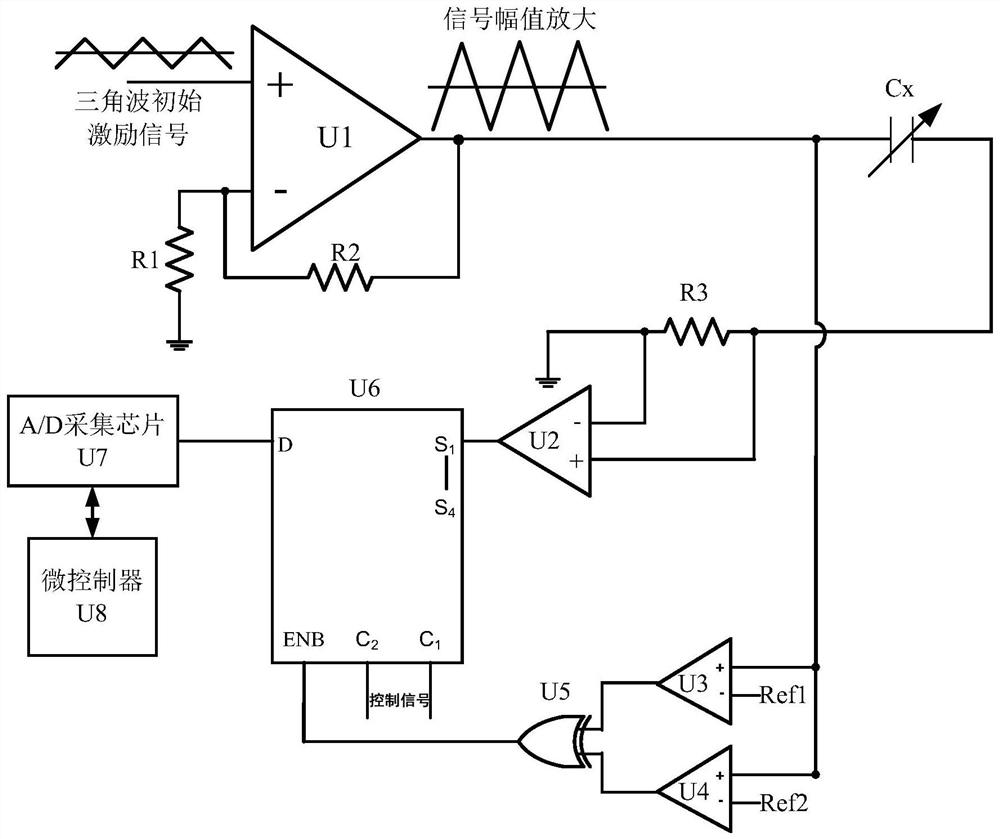

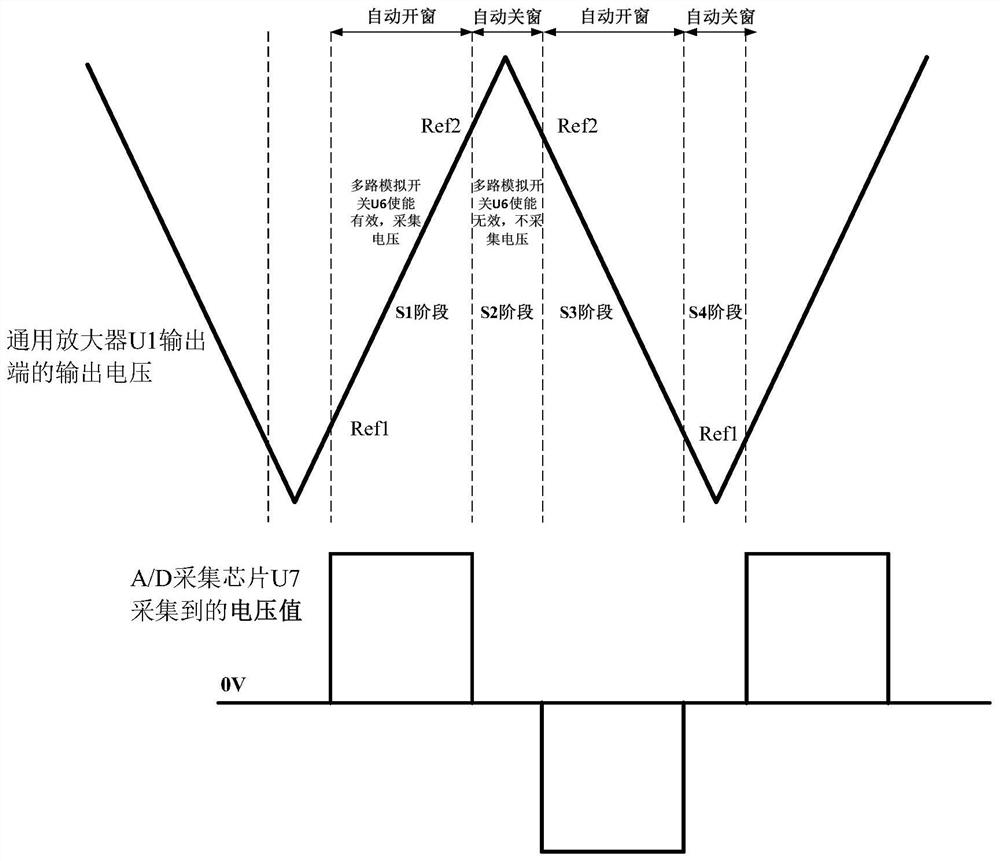

[0021] combine figure 1 and figure 2 The present invention is described in further detail.

[0022] Such as figure 1 As shown, the present application provides an aviation fuel quantity sensor measurement circuit based on a triangular wave automatic window opening mechanism, and the circuit includes a general amplifier U1, a differential amplifier U2, a first comparator U3, a second comparator U4, and an exclusive OR gate U5 , multi-channel analog switch U6, A / D acquisition chip U7, microcontroller U8, first resistor R1, second resistor R2, sampling resistor R3, oil quantity sensor Cx, wherein:

[0023] The anode of the universal amplifier U1 is connected to the triangular wave initial excitation signal, the negative pole of the universal amplifier U1 is connected to one end of the first resistor R1; the other end of the first resistor R1 is grounded; the output end of the universal amplifier U1 is respectively connected to one end of the second resistor R2, One end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com