Remote control wagon balance detection device and detection method thereof

A detection device and remote control technology, applied in the direction of measurement device, detailed information of weighing equipment, instruments, etc., can solve the problems of inability to detect the nature of truck cargo, single function of weighbridge detection device, affecting measurement accuracy, etc., so as to improve measurement accuracy. performance, improve road safety, and improve measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

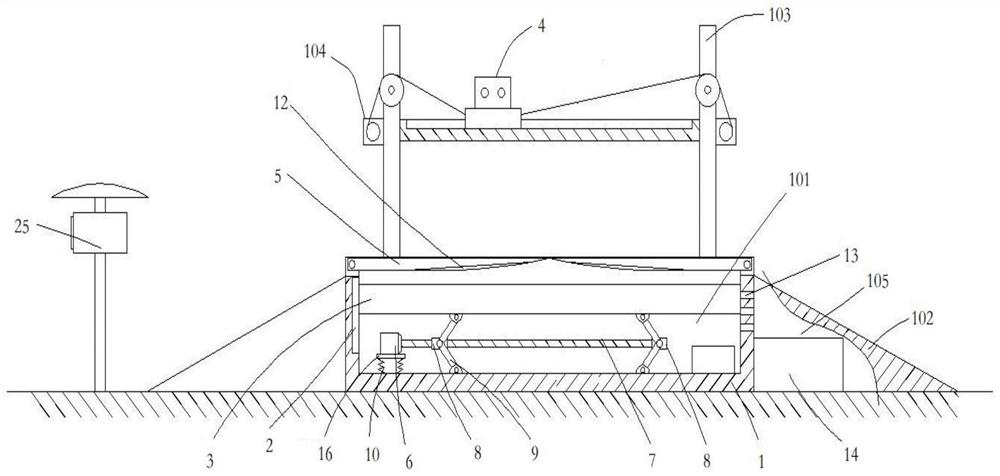

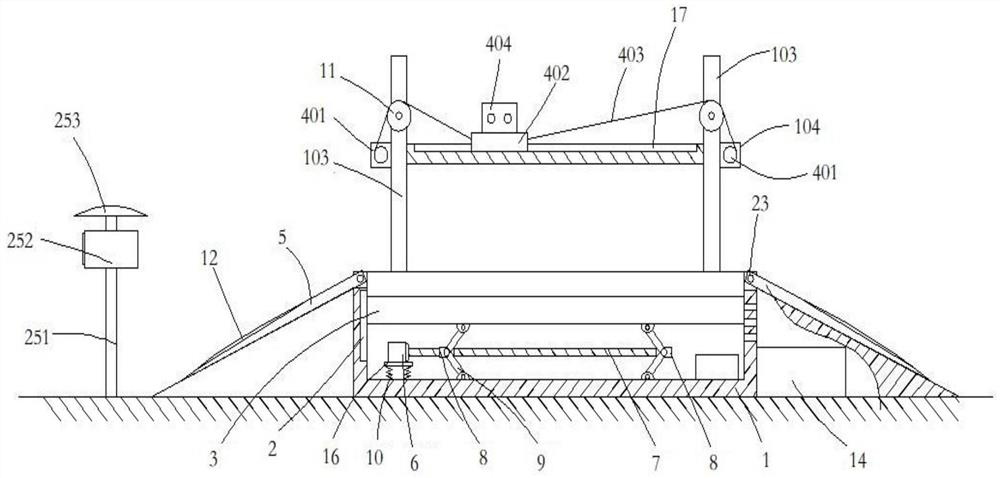

[0039] Such as Figure 1-3 As shown, a remote control weighbridge 3 detection device includes a detection platform 1, a lifting mechanism, a weighbridge 3, a rotating mechanism, a detection mechanism 4, and a control system;

[0040] A storage tank 101 is provided on the detection platform 1, the lifting mechanism is installed in the storage tank 101, the weighbridge 3 is installed on the lifting mechanism, and the side wall of the storage tank 101 is provided with a fan 2;

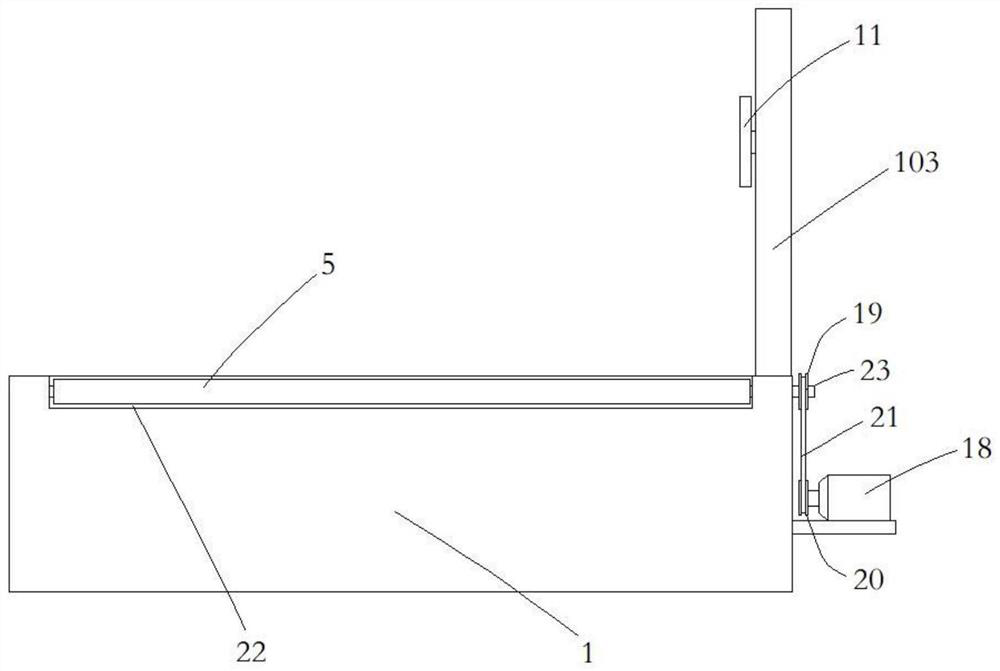

[0041] The rotating mechanism includes a driving device and a rotating plate 5, the driving device is installed on the detection table 1, the rotating plate 5 is connected with the driving device, and the rotating plate 5 is covered on the storage groove 101;

[0042] A vertical pillar 103 is also fixed on the detection platform 1, and a transverse pillar 104 is fixed on the vertical pillar 103, and the detection mechanism 4 is slidably arranged on the transverse pillar 104;

[0043] The lifting mechanis...

Embodiment 2

[0072] This embodiment provides a detection method of a remote-controlled weighbridge 3 detection device, using the remote-controlled weighbridge 3 detection device in Embodiment 1 for detection, specifically comprising the following steps:

[0073] S1: The control system receives the signal for detecting vehicle information, controls the drive device to start, and the drive device drives the rotating plate 5 to turn over, and the storage tank 101 is opened;

[0074] S2: The control system controls the lifting mechanism to start, and the lifting mechanism drives the weighbridge 3 to rise to the surface of the detection platform 1;

[0075] S3: the vehicle travels to the detection platform 1, reaches the weighbridge 3, and detects the weight;

[0076] S4: the control system controls the detection mechanism 4 to start, and the detection mechanism 4 slides reciprocally along the transverse pillar 104 to detect the cargo information;

[0077] S5: The vehicle drives away from the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com