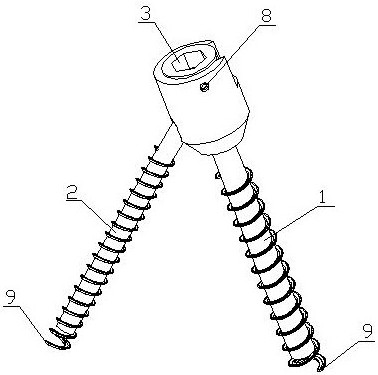

Zero-incisura conjoined screw for adjacent vertebral bodies

A zero-notch, screw technology, applied in the direction of internal fixator, internal bone synthesis, fixator, etc., can solve the problems of easy loosening, non-rotation resistance, and easy fracture of screws, and achieves increased anti-rotation balance, strong stability, Strong pull-out effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

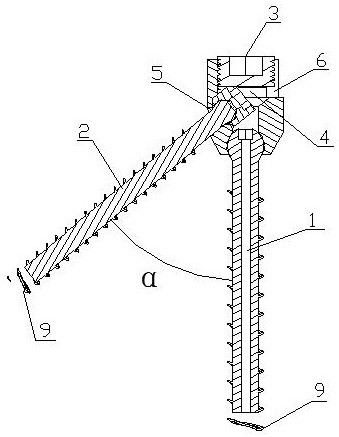

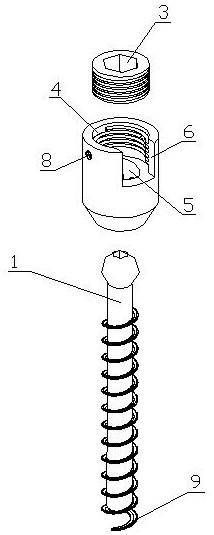

[0036] Embodiment 1: The doctor fixes the main screw 1 on the patient's vertebral body, inserts the auxiliary screw 2 into the screw oblique insertion hole 5 through the screw receiving groove 4, fixes the auxiliary screw 2 on another adjacent vertebral body, and The locking nut 3 is screwed into the screw receiving groove 4 to compress and fix the auxiliary screw 2 .

Embodiment 2

[0037] Embodiment 2: The doctor fixes the main screw 1 on the patient's vertebral body, inserts the auxiliary screw 2 into the screw oblique insertion hole 5 through the screw receiving groove 4, and fixes the auxiliary screw 2 on another adjacent vertebral body. The locking nut 3 is screwed into the screw receiving groove 4 to compress and fix the auxiliary screw 2 . Because the auxiliary screw 2 is relatively large, it is difficult to put it directly through the screw receiving groove 4, and it is more convenient to insert the screw mounting groove 6 into the screw oblique insertion hole 5.

Embodiment 3

[0038] Embodiment 3: The doctor fixes the main screw 1 on the patient's vertebral body, inserts the auxiliary screw 2 into the screw oblique insertion hole 5 through the screw receiving groove 4, fixes the auxiliary screw 2 on another adjacent vertebral body, and The locking nut 3 is screwed into the screw receiving groove 4 to compress and fix the auxiliary screw 2 . The lock nut 3 is pressed on the horizontal pressing surface 7 to make the lock nut 3 more stable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com